These New Solar Cells Are Modeled After a Fly’s Eye

Stanford University researchers may have found a way for perovskites to compete with silicon in the solar panel market

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/51/ab/51abb68e-6b7c-4ba0-a571-93a1cd8e0e4d/robber_fly_eye.jpg)

As far as elements go, silicon is second only to oxygen when it comes to abundance on Earth. For this and its properties as a semiconductor it has long been the backbone of electronics. The material is in everything from computer chips to radios. It’s the namesake, after all, of the modern tech industry’s hub in California, Silicon Valley.

Speaking of the sunny tech capital, silicon is the primary element used in solar panels. Three scientists at New Jersey’s Bell Telephone Company patented the very first silicon solar cell—the first solar cell to be considered practical, with its ability to convert 6 percent of incoming light into usable electricity—in the 1950s. The material has dominated the solar market ever since. Today, more than 90 percent of panels produced worldwide are crystalline silicon PV panels.

Silicon has earned so much status and market influence, with little competition in the solar space, that few know there are other options for solar.

Perovskites, or crystalline structures, are a new type of solar cell, made of common elements such as methylammonium lead iodide. Perovskites are easier to manufacture, and have the potential to convert sunlight to electricity at a greater rate than silicon cells. The challenge is that perovskites are extremely fragile.

Scientists at Stanford University, however, are taking a hint from nature. To make perovskites more durable, they have looked to the resilient structure of a fly’s eye.

The compound eye of a fly is comprised of hundreds of hexagonal segmented eyes each shielded with an organic protein “scaffold” for protection. The eyes are organized in a honeycomb shape, and when one fails, the others still function. The entire organ displays a redundancy and durability that researchers hope to recreate in solar panels.

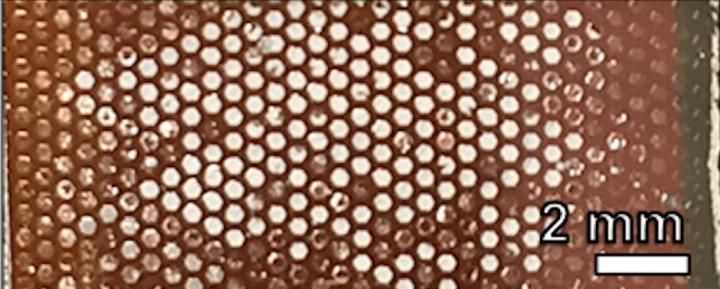

Reinhold Dauskardt and his materials science engineering group have created a honeycomb-shaped scaffolding, just 500 microns wide, from standard photoresist, or light-sensitive, material. To borrow another example from nature, just as a bee creates a honeycomb, and then fills it with honey, scientists build this protective structure and then make the perovskite inside it. They spin a solution of elements within the scaffolding, add heat and watch it crystallize to achieve the perovskite structure, and its photovoltaic properties. The scientists then coat the solar cell with a silver electrode to seal it and its ability to capture energy.

In a preliminary lab test, Dauskardt’s solar cells, which are about as wide as six strands of hair, maintained their structure and functionality. When exposed to high temperatures and humidity (185 degrees Fahrenheit and 85 percent relative humidity) for six weeks, the cells continued to produce electricity at consistent levels. The scaffolding around the perovskites didn’t deter from their electrical output either.

This is a game-changing accomplishment. Before this innovation, it was very difficult for researchers to manipulate and create photovoltaic perovskite cells, let alone for them to survive in the environment.

“When I gave talks in the beginning of organic photovoltaics, I would say, ‘if you breathe on these materials they’ll fail.’ In the case of perovskites, I say ‘if you look at them they’ll fail,’” jokes Dauskardt, principal investigator on the new study, published in Energy and Environment Science.

Perovskites can be up to 100 times more brittle than glass. But with the scaffold used to toughen it, the cell’s mechanical durability increases by a factor of 30. It adds both chemical and mechanical stability to the cell so that researchers can touch it without it breaking, and expose it to high temperatures with lower chance of deterioration.

Researchers at the University of Tokyo first explored the perovskite photovoltaic cell as an alternative to the silicon photovoltaic cell in 2009, and researchers around the world jumped into the field. Perovskite solar cells certainly have their advantages. Unlike silicon cells, which require high temperature processing to purify and crystallize, perovskite solar cells are relatively simple to manufacture.

“This is a breakthrough in one sect of perovskite research because it is solving problems that early-stage concepts face on the path to commercialization,” says Dick Co, director of operations and outreach at Argonne-Northwestern Solar Energy Research Center (ANSER). That said, he acknowledges that the development is not universally applicable to all perovskite solar cell research. There are so many ways perovskites solar cells can be made, and each lab has its own focus.

Since the crystalline structures can be made from various elements, there are also many aesthetic possibilities. The solar cells can be outfitted into windows, car tops or other surfaces exposed to light. Some companies are even printing the cells.

Co suspects perovskite solar cells will initially impact niche markets.

“I could see them being sold on iPad keyboard chargers, integrated into buildings and maybe on automobiles, such as the curved hood of a car,” he says. “But it’s hard to imagine making a [prototype] perovskite solar cell the size of a thumbnail big and widely deployed, especially when silicon solar factories are pumping out enough modules to cover small countries.”

Nonetheless, with improvements in efficiency and durability, researchers are on their way to making a cell ready to produce electricity in many environments. The researchers have applied for a provisional patent.

In Dauskardt’s test, the cells achieved a 15 percent efficiency rate, which is much higher than the first test in 2009 that converted 4 percent of light to electricity. Silicon panel efficiency rates rest around 25 percent, and in the lab, perovskites have achieved upwards of 20 percent. Researchers have estimated the theoretical efficiency capacity of photovoltaic perovskites at about 30 percent.

Dauskardt thinks his team may be able to improve upon the scaffold, originally built with cheap, easily available materials, to increase the cell’s efficiency.

“We were so surprised we could make one as easily as we could. Now the question is, are there better scaffolds that we can use? How can we recapture the light that would fall on the scaffold wall?” says Dauskardt. He and his colleagues plan to experiment with light-particle-scattering materials.

With the potential for cheap manufacturing, relatively quick commercialization (Dauskardt estimates within the next three to five years), and amazingly diverse applications, the perovskite solar cell may just make for the next great solar panel of the 2020s and beyond.

So when that fly is buzzing in your ear, rest assured that nature, in all its forms, inspires.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Headshot_MollyASeltzer.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Headshot_MollyASeltzer.jpg)