Drones are Ready for Takeoff

Will unmanned aerial vehicles—drones—soon take civilian passengers on pilotless flights?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/drones-Tad-McGreer-631.jpg)

During a test flight last year off the Pacific coast of Latin America, an aerial drone launched from the USS McInerney relayed back to the ship video of an open skiff speeding across the water. The frigate’s crew had long experience chasing drug smugglers, so they knew what they were seeing. The skiff was 20 miles ahead of the frigate and moving away as the sun went down. In the flight control room, operators instructed the drone to take up the chase.

Over the next three hours, the skiff stopped twice and shut down its engine—standard practice among smugglers listening for law enforcement aircraft. The drone, a 23-foot-long helicopter trailing a mile or two behind, was quiet enough to evade detection. It also had the range to keep up the pursuit when a manned helicopter, roughly twice its size, would have had to turn back and refuel. By the time the skiff made its rendezvous with a fishing boat under cover of darkness, the McInerney was on its tail. A flare went up as a boarding party moved in. The startled suspects began dumping contraband, but 132 pounds of cocaine was recovered when the smugglers were arrested.

Until now, drone aircraft have been confined largely to war zones—most recently in Libya—and they have become controversial for killing civilians along with insurgents. But critics and boosters alike say unmanned aircraft will increasingly be used for peacetime work. They disagree about the likely scale of the industry, but the Federal Aviation Administration is already considering new rules and training staffers to adjust to unmanned aircraft in U.S. airspace. “It’s not a matter of if, it’s a matter of when,” says Peter Singer, an analyst with the Brookings Institution. “Is it going to be 2012 or 2014? The point is, it’s going to happen.”

In fact, it’s happening now. Unarmed versions of the military Predator drone already patrol thinly populated stretches of the nation’s borders. Predators have also been flown over cities to assess damage after hurricanes, floods and earthquakes.When smoke grounded other aircraft during a 2009 forest fire in Circle, Alaska, a drone provided infrared imagery that allowed officials to determine that no evacuation was necessary. And during the accident this spring at Japan’s Fukushima Daiichi nuclear power plant, the world’s largest drone analyzed the emergency from high altitude, while a backpack-size drone inspected the crippled reactors at close quarters.

Drones will probably move first into jobs deemed “too dull, dirty or dangerous” for humans, says MIT automation expert Mary “Missy” Cummings. To monitor marine mammal populations off Alaska, for instance, oil companies have employed small manned aircraft flying at 300 feet, 200 miles offshore, in icy conditions. But a drone operated by the University of Alaska at Fairbanks recently did the job quietly enough not to scare off the animals. Police agencies are also lobbying for permission to use drones for building searches in hostage situations and for traffic management. With no need to carry people, drones designed for such work come in all sizes and shapes. Some look like a flying engine cowling (minus the rest of the plane) or a laptop with tail fins. Some are as big as a 737; others have the heft, and flapping wings, of a sparrow.

Some drones also look like conventional aircraft, and Cummings believes unmanned systems will ultimately replace even commercial pilots. She first saw the possibilities in the 1990s as a Navy pilot landing a highly automated F-18. “On carrier landings, it always did better than humans,” she says. At some airports today, Cummings notes, Boeing and Airbus jets take off, land and brake to a stop without human hands on the controls. She predicts that within ten years cargo planes will fly without human pilots and that passenger jets will ultimately follow.

First, though, somebody will need to work out some glitches: a few months after that drug bust at sea, Navy operators in Maryland experienced a “lost link”—like losing your wireless connection—with the same model drone, a Northrop Grumman Fire Scout, as it was traveling at 70 miles an hour straight toward Washington, D.C. The drone briefly entered restricted air space (within 40 miles of the capital). Military officers contemplated shooting down the 3,000-pound robotic helicopter over a heavily populated metropolis. But before anyone could scramble the F-16 fighter jets, technicians on the ground regained control and turned the drone back to base.

A good place to watch the developing drone revolution, with all its technological, commercial and ethical complications, is an hour east of Portland, Oregon, in the heart of the Columbia River Gorge, an area otherwise known for windsurfing, craft beer and political progressivism. Go almost anywhere on either side of the river—to an old school building in Bingen, Washington, say, or a former Chevy dealership in Hood River, Oregon—and you will find somebody working on drones.

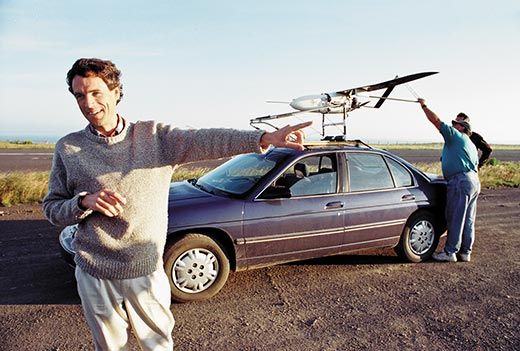

The aeronautical engineer who got the industry started here is a boyish, reclusive character in his mid-50s with the perfect garage-inventor name, Tad McGeer. He runs the Aerovel Corporation, a start-up with nine employees, tucked behind a dense wall of pine trees in the rugged hills above Bingen. The entrance is a narrow gravel driveway with a broken-down gate. A wrecked Cessna sits in a derelict barn, and cars cluster around a big, blocky house at the end of a hayfield.

Inside, a staffer fabricates plane parts in what was once a child’s bedroom, where the electronic controls for a coffin-like industrial oven now sit on a dresser decorated with beetles and snails. Aerovel’s mechanical engineering laboratory occupies another bedroom, with horses and hearts painted on the walls. Test engines roar in the garages at either end of the house, and if it all looks a little makeshift, that suits McGeer just fine.

“Aren’t we all amateurs?” he asks, his voice a low murmur that fades in and out like a distant radio station. “There are a lot of people doing what we do, tinkering in a garage.”

McGeer’s longtime business partner, Andy von Flotow, operates in similar fashion on a farm on the Hood River side of the gorge. But where McGeer tends to be cautious and constrained, von Flotow is about moving obstacles aside and getting business done. He has a gleeful farm boy bearing, with sun-bleached blue eyes and weather-reddened skin. He also has a high regard for calculations scratched on the back of an envelope.

In a pear orchard nearby, von Flotow points out a trailer insulated with five tons of hay. It houses a fan capable of blowing air at 80 miles an hour through a 1,500-foot length of white silage tubing stretched out over a hill. In a meadow on the other side, a cradle built on an old orchard crate is designed to hold a drone running its engine at full speed in the silent wind.

“This is my Mil-14 meadow,” von Flotow says, meaning that it meets military specifications for a sound-testing facility. (In addition to his partnership in Aerovel, von Flotow owns Hood Technology Corporation, which makes launchers, camera turrets and other military gear.) He uses the meadow in the dead of night to test different engine and muffler configurations. In springtime, the raucous calling of frogs in a nearby pond can pose a challenge. “So I phone the sheriff to tell them not to send the police and then I fire a shotgun twice.” That buys him 30 seconds of silence.

McGeer and von Flotow, both Canadians who earned doctorates in aeronautical engineering from Stanford University, have spent much of their careers as seat-of-the-pants inventors, solving problems fast and cheap. Their idea of engineering is making something for a dime that any fool can make for a dollar, and having fun doing it.

McGeer got started in drones working on one of the first civilian models, the Perseus, which made its maiden flight over the Mojave Desert in November 1991. The hole in the ozone layer was a hot issue then, and the idea was that Perseus would take sophisticated measurements of atmospheric chemistry at high altitudes over Antarctica. But McGeer soon split off to develop the Aerosonde, a drone with a ten-foot wingspan that could take routine weather measurements by moving autonomously up and down through the atmosphere. He named the company Insitu, Latin for “in place.” “It would not have been possible to conceive of the idea a few years earlier,” says McGeer, who could take advantage of newly miniaturized technologies, particularly lightweight receivers for the Global Positioning System (GPS).

By 1998, McGeer was regularly flying Aerosondes, often operating out of an old school bus von Flotow owned. But atmospheric research was a niche market at best, with few customers in sight. “Maybe it’s time for a stunt,” von Flotow suggested. He had in mind the first Atlantic crossing by an unmanned aircraft. “I didn’t want to do a stunt,” says McGeer. “I wanted to fix our problems. We needed to test-test-test, break, fix, test-test, but we didn’t have the money to do it.”

He lost four aircraft in 200 hours of flight that spring—an average of 50 hours between failures. But even at $25,000 apiece, his cost at the time, drones are meant to be expendable. McGeer figured that an Atlantic crossing would take about 25 hours, “and I said, ‘OK, so if we send four aircraft across the ocean, our chances that one will make it are better than 90 percent.’ ” A major defense contractor in San Diego was also planning the first Atlantic crossing, with a drone (and a budget) the size of a 737. The Los Angeles Times billed it as a David-and-Goliath contest.

That August, on Bell Island in Newfoundland, McGeer sent a rental car racing down the runway with an Aerosonde on top, the first of two launches that day. On South Uist Island in Scotland, a BBC crew set up movie cameras and waited. Back then, says McGeer, ground control could communicate with a drone for only about 50 miles at either end. The team programmed in GPS waypoints and prayed that the planes would find them on their own. The plan, developed with a meteorologist from the University of Washington, was to make the 2,000-mile crossing on 1.5 gallons of fuel. After both drones failed to arrive the next day, the BBC packed up and left.

Three days later, McGeer launched two more. On South Uist the next day, a blip flashed on a laptop screen, then disappeared, leaving the landing crew tensely waiting. Soon after, a drone dropped down from the sky and landed softly in the grass. McGeer got the word by phone, in classic mission control monotone: “We have something you lost.” When he returned his rental, McGeer was thinking, “‘This is a historic car!’ But we had scratched the roof a bit and decided not to mention it.”

The achievement attracted potential customers in the tuna industry, which had suffered a series of deadly crashes of fish-spotting helicopters. The Pentagon also “began to make cooing noises,” says McGeer; drones had been doing military work almost as long as there had been aircraft, with uneven results.

McGeer and von Flotow decided to focus on tuna. “Tad has a basic conflict with the Eisenhower military-industrial complex thing,” says Juris Vagners, a colleague who teaches at the University of Washington. “He wants to do civilian stuff.” For the tuna industry, McGeer and von Flotow developed the SeaScan, a drone with a camera turret. They also had to figure out how to make takeoff and landing user-friendly for fishermen working on the deck of a small ship. For the launch, they devised a catapult powered by a Sears, Roebuck air compressor, with a release mechanism triggered by a man yanking a rope. Recovery was more complicated.

McGeer eventually hit on the idea of flying one wing of the drone into a vertical rope, with the rope quickly slipping out along the leading edge of the wing to snag on a hook at the tip. Cutting the rope with the propeller wasn’t an issue because the prop is mounted at the tail, safely out of the way. The problem was developing a hook that would cause the plane to hang in midair, rather than slide down the rope and smash into the ground.

They tested mechanisms on von Flotow’s farm, using a plywood model of a SeaScan at the end of a five-foot rope. “I stood on a trailer and spun it around like a hammer thrower,” recalls Cory Roeseler, who does what he calls “grunt engineering” for McGeer and von Flotow. But instead of releasing it like an Olympic athlete, he sidled the model over to a vertical line stretched down the corner of a barn. “When you hit the line, you can figure out which hooks snag and which hooks fail. You can do that in an afternoon. Good ideas rise to the top quickly if you have some plywood, a cordless drill and some good thinkers.”

The “skyhook” technology they developed in this fashion is now used a thousand times a month, on land and sea, almost always without incident. But it is still a spectacle. The drone circles for its approach, then comes whining in at about 50 miles an hour. GPS devices on the skyhook and the plane communicate, like air traffic control talking to a pilot, and the plane adjusts to an accuracy of a half-inch or less. Then it slams into the rope and snags 25 feet in the air, causing the skyhook to buck and sway as in an earthquake. “That’s violent,” says a visitor seeing it for the first time. An engineer’s view, says McGeer, with a proud, parental smile, is, “Just violent enough.”

The changes McGeer came up with to attract the tuna industry also suited the military. Steve Sliwa, a college friend McGeer brought in to run Insitu’s business side, was soon steering the company into a closer alliance with Boeing for defense work. McGeer’s SeaScan became the ScanEagle, a 40-pound surveillance drone. During the Battle of Fallujah in 2004, the ScanEagle spotted would-be assailants and sent real-time video to troops on the ground. Military demand rose rapidly. There are now 18 ScanEagles aloft at any moment, according to Insitu, mostly in Iraq or Afghanistan, and the company is the largest employer in the Columbia River Gorge, where the boast is sometimes heard that while the Predator costs millions and works for generals, a ScanEagle costs about $100,000 and works for gunnery sergeants.

The ScanEagle carries no weapons, but its camera helps target military strikes, and videos sent back to Insitu sometimes showed Iraqis being engulfed in flames. McGeer struggled with what he was seeing, then quit the company in 2005. Three years later, Boeing purchased Insitu for about $400 million. According to von Flotow, he and McGeer split about 10 percent of the total. McGeer remains conflicted about it. “If you’re a dead Iraqi,” he says, “you might not think it worked out all that well.”

It’s a sentiment that echoes around the gorge, but quietly. Between them, Hood River and Bingen are home to fewer than 8,000 people, and neighbors inevitably run into one another at Brian’s Pourhouse or the Wednesday night Secret Salsa dance club. Nobody wants to blame the conduct of war on neighbors who build the hardware. “It would be like blaming a bank teller for the financial crisis,” says one local who works in the industry. Von Flotow acknowledges that “nobody’s happy about it.” Then he adds: “Most engineering nerds are basically apolitical.”

The question everyone asks is how quickly unmanned technology can make the leap into the civilian market. The potential seems limitless—handling routine monitoring of pipelines and power lines, for instance, or gathering geomagnetic data about natural resources (a job that entails flying hundreds of miles in a straight line, at low altitude, then moving 50 yards over and flying straight back). Drones could help farmers monitor crops in distant fields, allow real estate developers to perform simple construction jobs in remote or difficult locations or enable environmentalists to spot polluters.

But these applications face major regulatory issues. Drone proponents say that the FAA has limited the domestic market because of safety questions and that the State Department has shut off the international market by restricting the export of defense technologies. New questions about privacy and civil liberties are also certain to arise. For instance, Aurora Flight Sciences, a Virginia firm, is testing a drone to conduct “wide area surveillance” over cities. Where a human observer might detect nothing, says Tom Clancy, the company’s chief technology officer, computer algorithms can “extract behaviors or patterns of movement” suggesting ill intent—for instance, a car passing a bank four times before circling back and stopping. Would a court consider that probable cause for a police search?

The Brookings Institution’s Singer believes that the adjustment to drones will be as challenging as the adjustment to horseless carriages at the start of the 20th century. Regulatory issues are the main reason the Teal Group, aerospace industry analysts, recently estimated that the nonmilitary portion of the drone market will grow only to $500 million a year by 2020, up from $300 million now. Meanwhile, the military market will double, from $5 billion worldwide today.

The problem, says John Allen, the FAA’s director of flight standards, is that “there are too many lost [communications] links now. Some would say it’s not that big a deal—‘The aircraft continues to fly, it’s not going to come plummeting to earth.’ ” Drones are typically programmed to go into a holding pattern—or return to base—when they lose contact with ground control. “Well, that might be fine in a combat environment,” Allen says, “but in a civil environment, with a very congested national airspace, that creates a problem.”

Under current FAA rules, operators of unmanned aircraft must have a certificate of authorization; only 264 such certificates are active, most for research and development in remote areas. “What they would like,” says Allen, “is to not have to go for that permission every time,” and simply file a flight plan and take off, like manned aircraft. But human pilots can see and avoid small planes flying by visual flight rules. Many drones, he says, lack the technology to “sense and avoid.”

The FAA is considering rules that would continue to separate unmanned aircraft from conventional air traffic but relax restrictions on drones weighing less than 50 pounds and flying below 400 feet. Allen predicts the change, likely to take effect late next year, will spur entrepreneurs and government agencies to launch thousands of new drone applications. But opening the national airspace to larger drones—some with the wingspan of a passenger jet—will be more complicated, he says, requiring “a lot of cultural change” and more reliable technology.

One watchdog database lists more than 50 accidents involving large military drones since 2007. Most took place in Afghanistan or Iraq, where combat sometimes requires pushing a drone to unsafe extremes. But a Predator providing surveillance along the Mexican border crashed in this country, when an operator accidentally shut off its engine. Officials at U.S. Customs and Border Protection and the FAA disagree about whether the Predator’s domestic record adds up to a few minor mistakes over four years of safe civilian operations—or 350 times the accident rate for commercial aviation.

The concern expressed even by some in the drone community is that a careless accident early on could be a disaster for the entire industry. The first fatality involving a civilian drone has already occurred. In August 2009, a Yamaha RMAX helicopter, a commercial drone about the size of a motorcycle, crashed while crop-dusting a field in South Korea. Part of the rotor sheared off and penetrated the abdomen of a bystander, who bled to death. Yamaha has since halted RMAX production.

“We have accidents more often because we’re not carrying people,” says Sliwa. “The safety systems on manned aircraft are designed for a ten-to-the-minus-six probability of an accident.” That’s one in a million. For unmanned aircraft, he said, it’s more like a ten-to-the-minus-four thing. That’s one in 10,000. “But we’ll get there. Back when our parents were growing up, there was a form of transport you would not get into without a human operator, and that was an elevator. Now we step in and push a button.”

But the real obstacle, McGeer argues, isn’t regulation—it’s cost. There are a lot of human pilots out there, and they love what they do. So their services come cheap. You can rent a piloted Cessna for as little as $100 an hour, he says.

Unmanned aircraft typically require at least two people, and sometimes many more, doing ground control. The work involves sitting in front of a computer for hours at a time, so no one does it for fun. Drones also represent a relatively new technology, with high research and other start-up costs for a product that’s still manufactured in relatively small numbers.

Costs will almost inevitably come down. For instance, it may be possible to develop systems that enable one ground controller to handle four or five drones at a time. To alleviate FAA concerns about that approach, Insitu executive Paul McDuffee suggests, a UPS or FedEx plane might have one human pilot to communicate with air traffic control—and three unmanned planes flying in formation behind. It is, he acknowledges, “a Buck Rogers theoretical concept.” McGeer is skeptical. Congressional earmarks may support a few civilian uses, but earmarks are drying up. For now, he believes the military is likely to remain the primary buyer of unmanned aircraft.

In an alley between two vineyards on his farm, von Flotow watches staffers use a catapult launcher to fire a 150-pound hunk of rusting steel up a zip line. They’re testing brake systems to stop the hunk of steel before it comes slamming back down. They need to get the braking right because this is how they will soon test a new multimillion-dollar military drone packed with pricey electronics.

To a casual observer, it looks like boys on the farm having fun. But they’re working on a joint Navy and Marine contract recently won by Insitu, and, von Flotow says, it is complicating their lives. Instead of getting an idea and trying it out the same afternoon with a cordless drill and some plywood, “we have to wait for hundreds of guys in Maryland to tell us what to do,” he says. And instead of working for the fun of it, they must now account for their time in ten-minute increments. What they used to do for a dime can end up costing a dollar.

Over at Aerovel, meanwhile, McGeer is back where he started 20 years ago, thinking about the weather. What he has in mind is a drone that could take off from the West Coast, land itself on a ship in Hawaii to refuel without human assistance, then take off and fly home again, over and over, continuously sending back low-altitude weather data. It is a typically quixotic project. The lack of good storm-intensity forecasts has huge economic costs, but filling that need won’t automatically generate big profits because the economic benefits are too widely diffused.

McGeer wants to accomplish the new mission with a drone that can take off and land vertically, eliminating launchers and skyhooks. Vertical takeoff and landing, or VTOL, is “historical snake oil in the aeronautical industry,” he admits. For decades, science magazines have conjured up futuristic visions of such vehicles taking off from people’s driveways, but the trade-offs required to get both the hovering ability of a helicopter and the forward speed of a fixed-wing aircraft have grounded most such aspirations. McGeer thinks he has a better idea, and new technology to make it happen.

The test drone stands on the driveway outside his garage, its engine roaring. It’s just a stripped-down tube, capable only of takeoffs and landings, not horizontal flight. For now, the wings are just a stick, like a scarecrow’s arms. Lately, the engine has been dying mysteriously after two or three hours. A staffer has put in an order for a carburetor rebuild kit, but it will take a day or two to arrive. “Isn’t it just a chain saw carburetor?” McGeer asks. It starts to rain, which is a problem because they haven’t sealed up the avionics yet. McGeer is undaunted. The “test-test-test, break, fix, test-test” mantra is his life.

Better to come back another day, he suggests. He isn’t making any promises. But it might just fly.

Richard Conniff is a frequent contributor to Smithsonian. Robbie McClaran, who photographed oncologist Brian Druker for the magazine’s May issue, is based in Portland, Oregon.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/richard-conniff-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/richard-conniff-240.jpg)