The Next X-Plane

Who will win the competition to build an airplane that can fly fast and hover?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/fc/6d/fc6d6e3b-8f54-4d77-a825-8cae4822bce8/15l_on2015_phantomswiftdarpavxpsourceboeing_live.jpg)

No one has ever set the bar for the dream machine of aviation higher than Alexander Klemin did on April 26, 1938. Testifying at a Congressional committee hearing on “Development of the Autogiro and Rotary-Winged Aircraft,” the renowned chairman of the Daniel Guggenheim School of Aeronautics at New York University said that “[t]he conquest of the air in its broadest sense will only come when we can do in the air substantially everything that a bird can do in the air.” Three-quarters of a century later, the Defense Advanced Research Projects Agency is preparing to announce which of four competing aircraft designers it thinks might come closest to fulfilling Klemin’s vision. The winner will receive a $90 million contract to build and fly a technology demonstrator DARPA calls the Vertical Take-Off and Landing Experimental Aircraft, or VTOL X-Plane.

By “substantially everything a bird can do in the air,” Klemin meant take off and land almost anywhere, fly fast, and hover. Some aircraft can do some of those things today; DARPA wants an X-plane that can do them all and do them better. The goal is not a production aircraft or a VTOL craft suited to a specific mission, according to Ashish Bagai, DARPA’s manager for the VTOL X-Plane. Instead, Bagai told the American Helicopter Society International last May at its annual conference, the aim is to “push the boundaries out of our dominant design space that we have today.”

The invention of the helicopter transformed aviation. But in 1938, when Klemin spoke to Congress, the question he was addressing was whether taxpayer money spent on developing aircraft with rotors would be wasted. Klemin believed the investment would advance U.S. aviation, and his answer was quickly confirmed: In September 1939, Igor Sikorsky demonstrated his VS-300, the first useful American helicopter, and the age of vertical-lift aircraft began.

More than a decade passed before the first whirlybirds went into widespread use, but designers discovered almost immediately that the speed of any helicopter would be limited by the aerodynamics of rotors. Rotors work well in a hover, when their blades turn around a stationary axis, but in forward flight, air hits the rotor blades at dramatically different speeds as the blades advance in the direction the aircraft is traveling or retreat toward whence the aircraft came. This is the primary reason that, as Bagai told the AHS briefing, the fastest conventional helicopters top out at around 175 knots (200 mph). Fixed-wing airplanes can fly much faster, but the ones that can take off and land vertically—the AV-8 Harrier, the F-35B Lightning II, and the Russian Yak-38 Forger—can hover for only a short time, riding on small columns of rapidly moving air. An efficient hover is best achieved by moving a large volume of air downward relatively slowly.

Dozens of designers have tried to combine the agility of a helicopter with the speed of an airplane by marrying one or more methods of propulsion—rotors, propellers, turbojets, or ducted fans—with one of four ways to convert a craft from vertical to horizontal flight: tilting the whole aircraft, tilting the thrust, deflecting the thrust downward for vertical flight and rearward for horizontal flight, or using two thrust mechanisms on the same vehicle (such as rotors for vertical flight and prop fans or jet exhaust for horizontal flight). A graphic called the “V/STOL Wheel of Misfortune,” its original creator lost to history, is easily found on the Internet; updated versions depict 45 vertical/short-takeoff-and-landing piloted concepts that actually were built, some of which look downright daft. “Time and again, the compromises necessary to combine the hover capability of a rotorcraft with the high forward flight speed of a fixed-wing aircraft were deemed to be unacceptable, particularly the costs of development, production, and operating these V/STOL concepts,” writes Mike Hirschberg, who developed a modern V/STOL Wheel of Misfortune while working on the F-35 program and is now the executive director of AHS.

The only four to go into production are the Harrier, the Yak-38 and F-35B jet fighters, and the V-22 Osprey tiltrotor troop transport, which swivels two large wingtip “proprotors” upward to take off and land like a helicopter and forward to fly like an airplane. That enables the Osprey, now in service with the United States and, soon, Japan, to cruise at 275 knots, roughly double the cruising speed of most military helicopters. Though the Osprey can hover, it doesn’t do so very efficiently, in part because speedy forward flight requires the proprotors’ blades to be short and heavily twisted, and in part because the craft has high disk loading (the total weight of the aircraft divided by the area of the circle its rotor blades describe). “Nearly all of the aircraft shown on the V/STOL Wheel—all of which were built and flown—could have been fielded, given enough time, money, and willingness to accept compromise,” says Hirschberg. “But they needed to have a compelling capability over less expensive, less complicated conventional aircraft of their day.” What the VTOL X-Plane program, also known as the VXP, is trying to do is to come at the problem by combining the lessons learned over the past 75 years with new technology and new ideas.

DARPA’s Bagai says a key VXP requirement is “the ability to hover and to perform sustained hover. That’s an attribute of vertical flight that’s important. That’s why we have helicopters today, because nothing else can do those missions that helicopters can do.” Speed, he says, can be gotten pretty much just by adding power: “We know how to fly barn doors fast.” He should know. When at Sikorsky, he was principal engineer on the X2 high-speed technology demonstrator, a compound helicopter—coaxial rotors with a pusher propeller—that won the Collier Trophy in 2011 for setting an unofficial helicopter speed record: 250 knots in level flight.

In March 2012 Bagai came to DARPA and started the VTOL X-Plane project, the sort of experimental project DARPA was made for. The agency doesn’t produce military equipment; instead, it funds farsighted, sometimes far-fetched research to help keep the military on the cutting edge of technology. If DARPA’s projects bear fruit, the results are handed over to the military for possible development. For example, the agency did some early work on the lift fan technology used in the F-35B, but has no direct role in F-35 production.

The VTOL project kicked off in 2013, when the agency awarded preliminary design contracts of $11 million to $17 million each to four competitors. Two of the awards went to some of America’s top military aviation manufacturers: Boeing and a Sikorsky–Lockheed Martin team. The other contracts went to smaller companies headed by two of the country’s most inventive aeronautical engineers: Aurora Flight Sciences, whose chief designer, John Langford, got his start heading a team that set a world record for human-powered flight, and Karem Aircraft, founded by Abraham Karem, who among other achievements invented the Predator drone.

The four contestants are offering dramatically different solutions—all unmanned, an option DARPA offered to speed the work.

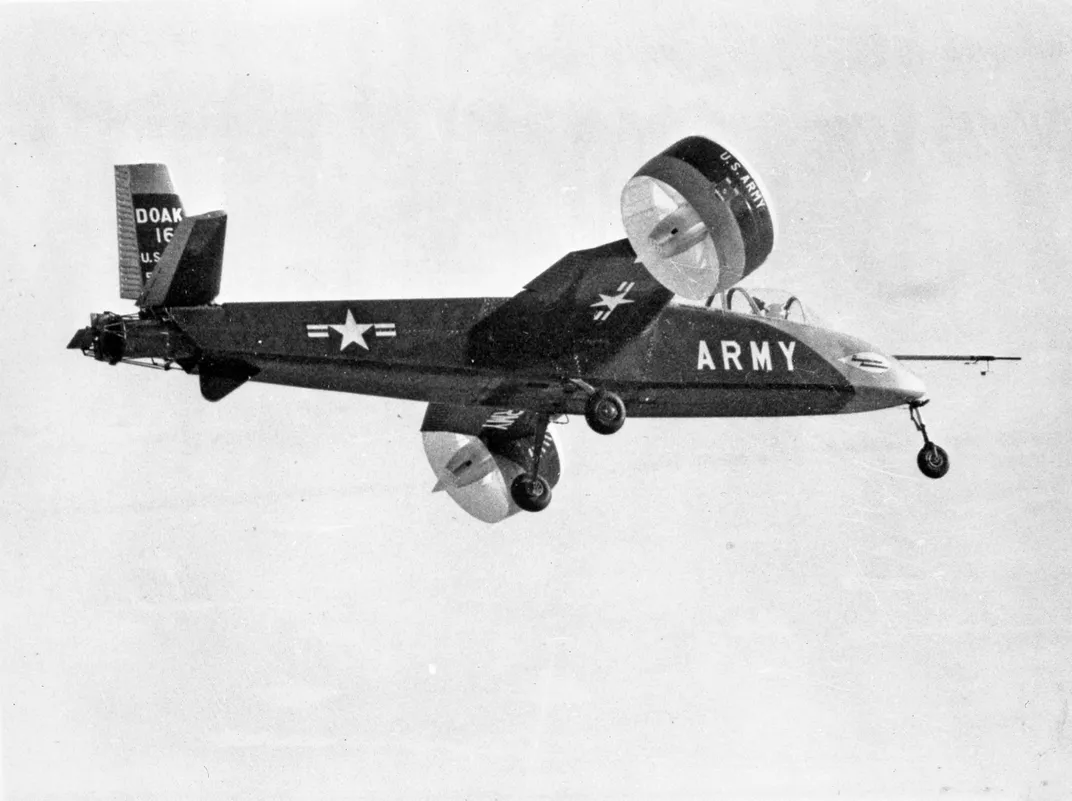

Boeing ($17 million)

Boeing relied on its Phantom Works rapid prototyping facility to come up with its entry, Phantom Swift. The fuselage, roughly 44 feet long and 7.5 feet wide and shaped something like a surfboard, houses two large ducted fans, one fore and one aft of its centerpoint, and one smaller, swiveling ducted fan on each wingtip (Boeing declined to reveal the diameters of the fans). Project director Brian Ritter says the configuration echoes a Wheel of Misfortune aircraft called the Doak Model 16 VZ-4, an essentially conventional aircraft that also had swiveling ducted fans on its wingtips. “We refer to them as wingtip thrusters and body lift fans,” Ritter says, adding that Phantom Swift uses a “four-post lift approach” for vertical flight and hover. After vertical takeoff, louvers at the bottom of the lift fans in the fuselage can be used for maneuvering in a hover or closed entirely for forward flight. The body lift fans then shut down while the wingtip thrusters tilt forward to make the craft fly like a conventional airplane.

“We have the ability to control thrust [independently] on all four fans,” Ritter says. “We have louvers in the bottoms of the body lift fans which can provide directional control. We have the ability to rotate our wingtip thrusters independently and help provide directional control. And then, by controlling the thrust out of each of those fans, all of those different things combined provide the means for low-speed directional control.” At high speed “you’ve got full flying tails and flaperons on the aircraft as well,” Ritter adds. “So we’ve got maneuverability and agility, in addition to just the wingtip thruster control in forward flight.”

Power for Phantom Swift comes from two GE CT7-8 engines, a variant of GE’s 700 series, which are used in Sikorsky’s S-92 multi-role helicopter. Boeing built no subscale demonstrator to test its concept in flight, but Ritter says some “young engineers” at the Phantom Works built a six-foot model as “a marketing tool during the proposal stage”; a video of it flying in a lab can be found on YouTube.

It would be “very easy” to build manned or unmanned versions of the Phantom Swift, Ritter ventures, scaled down from the VXP’s required 10,000 to 12,000 pounds to as little as 4,000 pounds. Scaling Phantom Swift up to 24,000 pounds also could be done, he says, though “it’s going to take some engineering design.” Nevertheless, Ritter adds, “when we look at this, we see a great X-plane and fun opportunity to demonstrate new technology—but also the makings of a new product line.”

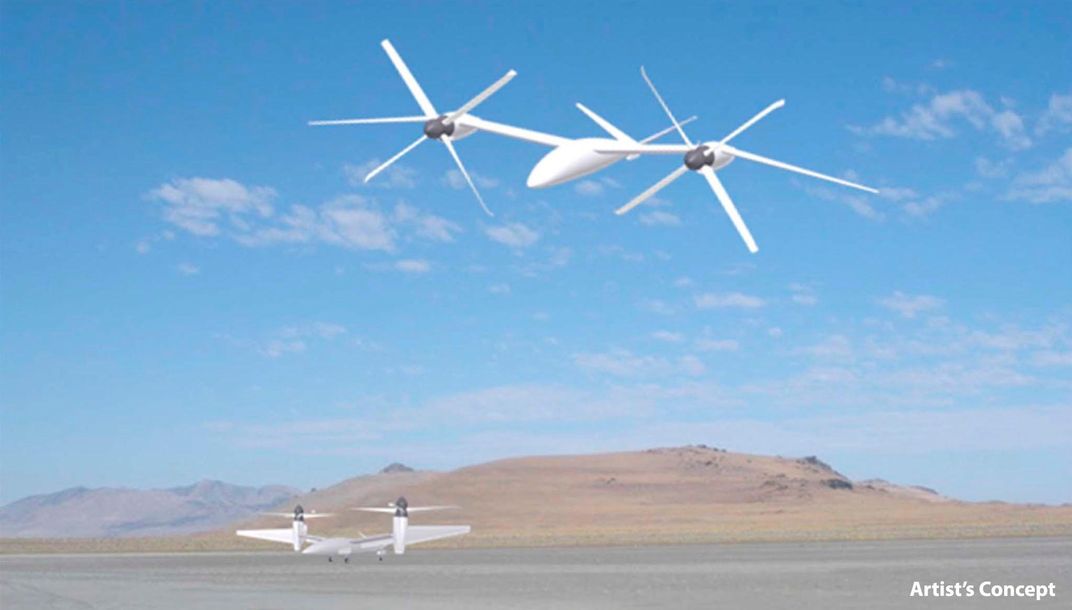

Aurora Flight Sciences ($14 million)

John Langford’s company is developing the most unconventional entry: a hybrid electric tilt-wing aircraft using an avant-garde form of thrust called distributed electric propulsion, something NASA is also experimenting with. The thrust for LightningStrike, as Aurora calls its design, will be produced by 24 ducted fans, 18 embedded in the tilting wing and another six in a tilting canard. The fans are to be driven by three megawatts of electricity, equivalent to 4,023 horsepower, produced by three generators powered by a single Rolls-Royce AE 1107 turbine engine, the one used on the V-22 Osprey. No batteries required.

“It is a strange-looking airplane,” Langford allows, but “one of the things distributed electric propulsion gives you is this incredible freedom to integrate the aerodynamics and propulsion together.” The amount of power sent to each of the 18 wing fans (31 inches in diameter), and to the canard fans (21 inches in diameter), can be varied according to complex algorithms executed by triply redundant flight control computers. “There’s essentially a nozzle at the back of each of these, and you can change the thrust of each of these individually, so you can change the lift distribution and you can get very powerful controls,” Langford says. The configuration, he adds, “allows you to operate each piece of that wing at its maximum performance condition throughout the hover and the transition and the forward flight regime,” so you avoid losing lift because, say, a rotor is blowing down on the wing.

For the VXP competition, the LightningStrike is unmanned and fully autonomous; no remote control pilot, as is used with the Predator and many other unmanned aircraft. But add a cockpit and the LightningStrike can be manned. It can also accommodate a cabin between the wing and canard, able to carry six troops or passengers. Langford adds that the design can be easily scaled up or down; the individual lift fans “almost become like Legos. You can add or subtract them.”

Unlike the other entrants, Aurora built a one-fifth-scale model demonstrator—made largely with 3D printing—and as of press time planned test flights in September at Naval Air Station Patuxent River, Maryland, to validate data collected in wind tunnel tests. The LightningStrike will be “as maneuverable and agile as a helicopter, certainly,” says Carl Schaefer, Aurora’s program manager, “but I think where you’ll see it most maneuverable and agile is in its forward flight regime. It’s got tremendous roll rates, very good pitch rates. It’s a sports car, frankly.”

Karem Aircraft ($11 million)

Also seeing a new product line: Abraham Karem, in his VXP entry. Along with the Predator UAV (see “The Drone Started Here,” Apr./May 2013), Karem invented the Optimum Speed Rotor, a technology that enables a helicopter rotor to operate “at an optimal angular velocity in revolutions per minute (RPM) minimizing the power required to turn the rotor and thereby resulting in helicopter performance efficiency,” as his patent explains. Karem has adapted that invention to design a series of Optimum Speed Tilt Rotors of various sizes, including his VXP entry, the TR36XP.

Named for the 36-foot diameter of its two rotors, the TR36XP is a willowy aircraft. It has a 40-foot fuselage with an upward V-tail and a long, slender wing—100 feet in span. The portions of the wing outboard of the rotors tilt with them. “The rotors are large compared with other configurations, and they move a lot of air, so the speed of the rotor downwash is quite modest,” Karem says. Benjamin Tigner, Karem’s director of advanced systems programs, says the TR36XP is “more maneuverable than most helicopters because the rotors are so rigid, and the pilot can yank the airplane around quite aggressively when needed.”

The craft’s rotors, whose rpm can be reduced as much as 50 percent when less thrust is needed in forward flight, will be powered by two Turbomeca RTM 322 engines producing 2,540 shaft horsepower each. If one engine fails, a shaft connecting the rotors will keep them both turning. Karem says that’s because its rotor diameter is large compared to the weight of the aircraft, the TR36XP could “very nicely” autorotate to a safe landing if both engines were lost.

Like the other entrants, Karem’s tiltrotor, if selected, will be unpiloted, but the concept is “mainly designed with manned applications in mind,” Karem says, and his company has been working on such designs for years. “We have designed and analyzed [optimum-speed tiltrotor] vehicles in many different sizes and many different applications, ranging all the way from around 10,000 pounds up to a 250,000 pounds takeoff weight. The risk reduction provided by a DARPA VTOL X-Plane demonstration could be leveraged for the benefit of both the military services and the VTOL industry to build new vehicle types with capabilities and utility well beyond today’s helicopters.”

Given all the work his company has done on the concept, Karem says, the team felt no need to build a subscale demonstrator. “Many of the challenging aspects of the OSTR [optimum-speed tilt rotor] technology have been proved in flight,” he says.

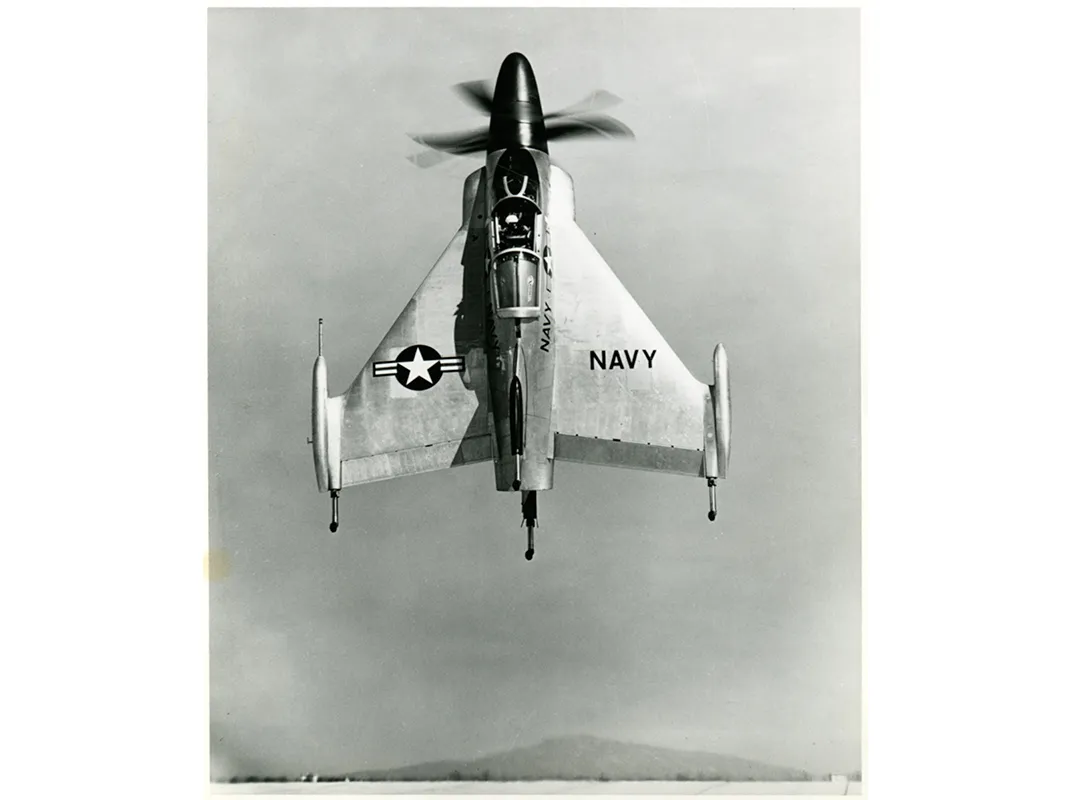

Sikorsky/Lockheed ($14.4 million)

Working with Lockheed Martin’s famed Skunk Works, the Sikorsky team is offering a design whose likeness can be found only on the Wheel of Misfortune. It’s a tailsitter. The 1950s Convair XFY-1 and Lockheed XFV-1 were Navy-financed Pogos: Sitting on their tails, they pointed straight up for take off and landing. Big counter-rotating propellers on their noses did the lifting. “The poor pilot was looking over his shoulder trying to land the thing nose-up,” says Linda O’Brien, Sikorsky’s program manager. But that won’t be a problem for Sikorsky’s Unmanned Rotor Blown Wing, which won’t carry a crew and will be flown by computers. “Autonomy gives a lot of flexibility in flying a vehicle like this,” O’Brien says.

An artist’s rendering shows an aircraft whose 36-foot wingspan holds two stationary proprotors, each 15 feet in diameter and positioned midway between wingtip and centerline. Between the rotors, the wing sports a pod, similar to the cockpit placed between the engine nacelles on a World War II P-38 Lightning. Unlike the P-38, the Sikorsky VXP lacks pylons leading to a horizontal tail. Instead, behind each of the proprotors—or under them when the aircraft sits on its tail—is a vertical tail at right angles to the wing that extends both up and down in horizontal flight.

O’Brien says a tailsitter is “the simplest way to capture VTOL and speed because there’s no morphing of the aircraft. It takes off on its hind legs, so to speak, pitches over, and transitions into forward flight. You don’t expend the weight and system complexity to morph or pivot or transform the airplane in any way.” The Unmanned Rotor Blown Wing is meant to stay that way, but O’Brien says the companies have concepts for “tilt-wing versions of this that you could put a human in.”

Mark Alber, manager of advanced concepts at Sikorsky and chief engineer on the project, says the aircraft is called the Rotor Blown Wing because, given the size of the proprotors, “there is a very high percentage of the wing that’s being blown by the rotor wash.” This provides extra lift that enables the craft to have a smaller wing and greater speed. O’Brien predicts the aircraft will fly “significantly” faster than the minimum 300 knots DARPA requires.

DARPA project manager Bagai refuses to discuss how the winner of the competition will be chosen. Nor will he venture whether the result might meet the “substantially everything a bird can do in the air” standard. In some ways, Bagai argues, Klemin’s vision was exceeded long ago. Not that many birds can hover, he notes, and none flies faster than the speed of sound. But birds far outclass manned aircraft in maneuverability and, he admits, in the way they can quickly land on a tree branch or telephone line.

As for the more practical question of how much the VTOL X-Plane project will advance vertical flight, Bagai says, “Whether the types that we’re developing right now are the concepts that darken the skies or it’s a spinoff from that that darkens the skies, I think either way it’s a huge ramification.” Were he alive, Klemin would surely be pulling for the designers to prove Bagai right.