Designing a Moon Suit for the 21st Century

The date for the next lunar landing has been set, but the astronauts don’t have a thing to wear.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/7a/84/7a8435fc-a433-4e32-acde-f45e4f423373/40a_on2019_1-20190712_spacedayonhill_1398_live.jpg)

One of the last times former astronaut John Grunsfeld was in NASA’s immense underwater training pool in Houston, wearing a spacesuit and practicing for his third and final Hubble Space Telescope repair in 2009, he felt a growing pain in his shoulder.

He was only weeks from liftoff, and the telescope’s fate—as well as a substantial NASA investment in his training—was on the line. He knew right away what might be causing the pain: a rotator-cuff tendon injury. He knew because after his second Hubble repair mission in 2002, he had needed surgery to repair significant tendon damage in his other shoulder.

He was also aware that other astronauts—as many as 25, according to NASA—had experienced similar shoulder problems, and that the design of the suit’s shoulder joint appeared to be associated with at least some of these injuries. Under the suit’s fabric was a stiff “hard upper torso” made of fiberglass, which can restrict shoulder motion and put increased strain on the rotator-cuff muscles, especially when the astronaut was in a sideways or upside-down position. This issue had been brought to the attention of NASA officials years earlier, but the costly-to-replace suits were still being used.

Grunsfeld had to decide. “If it was just a little bit worse, I don’t think I could have gone [on the Hubble repair mission],” he says. But given the stakes, he continued preparing for the flight. As it turned out, he and his fellow astronauts succeeded in upgrading the telescope during a series of EVAs (extravehicular activities, or spacewalks) that stretched to almost eight hours each. Moving his shoulder was in fact much easier in weightlessness. But Grunsfeld knew what he was likely to face back on Earth. Sure enough, soon after returning, he had a second rotator-cuff surgery. Not long after, he retired from the astronaut corps.

Grunsfeld is quick to say that NASA spacesuits do their job and have kept hundreds of astronauts safe over the years. A strong advocate for human space exploration who went on to head NASA’s science program, he doesn’t want the agency to quit doing spacewalks or making spacesuits for missions to the moon, asteroids, and Mars.

He just wants better ones.

Now, with NASA gearing up to send astronauts to the moon in 2024 (see “Moon Rush,” August 2019), it has become apparent that spacesuit development has not kept up with the times. Designs for suits—technically called Extravehicular Mobility Units or EMUs—have continued to evolve since the Apollo days, but the suit astronauts wear today is basically a modified version of what first went up on the space shuttle in 1981. And the current suit is made for weightless work outside the space station, not for hopping around in one-sixth G on the lunar surface.

If the moon program stays on schedule, spacesuits will within a few years be asked to do more than they ever have. They’ll have to be far more flexible and dust-resistant; they will have to keep astronauts safe for longer periods outside their spacecraft; they’ll need to be interchangeable among astronauts of different sizes, and, NASA hopes, less costly; and they will have to reduce the risk of injury. After all, there will be no surgeons onboard the lunar lander to fix an incapacitated shoulder.

Despite the long-standing awareness of these needs, there has been only limited testing of advanced suit technology outside the lab—a few modestly funded experiments conducted at remote desert locations or underwater habitats. There have been zero trials on the International Space Station, although these are due to begin this fall.

The reasons for this lack of progress have partly to do with changing requirements over the past two decades. Engineers would be working one year on a new suit for lunar exploration. Then it would be Mars or an asteroid. Each mission had slightly different technical demands, and the frequent change of destinations made the overall research program more complicated.

In addition, there was little or no competition in the spacesuit business for more than 40 years. The same company, Delaware-based ILC Dover, has outfitted NASA spacewalkers from Apollo through to the current space station era. This summer, in partnership with Collins Aerospace, which makes the suit’s life-support backpack, the company introduced an advanced EVA suit called “Astro,” which—perhaps looking ahead to a new era of private lunar missions—it developed on its own, instead of waiting for a NASA contract. Chris Hansen, manager of NASA’s EVA Office, would like to see many more players in the game.

Even before the 2024 deadline put spacesuit work on a fast track, he says the pace of development had already picked up. “About two years ago we came to the conclusion that we needed a new spacesuit that could be used on a wide range of missions,” he says. “Using our long experience and then new technologies and approaches, we’ve been making real progress. This is a super exciting time for us.”

It may be no coincidence that the speed-up in suit development happened around the same time as the release of a NASA Office of Inspector General report sharply criticizing the program. The IG identified almost $200 million in agency spending over a decade on three programs to develop next-generation suits. Despite this investment, the report concluded that “the Agency remains years away from having a flight-ready spacesuit capable of replacing the EMU or suitable for use on future exploration missions.”

The report also criticized NASA for paying $80.8 million between 2011 and 2016 to a Houston-based company called Oceaneering International that had been developing a spacesuit for the Constellation moon program, which was canceled in 2010. Not only were project managers advised a year later to terminate the Oceaneering contract, but subsequent work done by the company appeared to duplicate work done by the agency in-house, according to the IG. Hansen says that while NASA accepted much of the report, it took issue with the part criticizing the continued Oceaneering work, because the research and development produced under that contract had been valuable.

NASA’s next suit, called the Exploration EMU or xEMU, is being developed in-house at the Johnson Space Center in Houston, where the astronauts train. Numerous commercial suppliers are involved in its development, and once the design is final and the suit passes initial qualification tests, NASA will turn to industry for full-scale production.

One reason to keep the design in-house is the accelerated schedule for landing on the moon. Before Vice President Mike Pence announced the 2024 deadline at a National Space Council meeting last March, spacesuit research managers had been planning to have a next-generation suit ready by 2027. In the span of one short speech, they lost three years.

At a spacesuit technology workshop held in Houston in late July, there was much talk about the deadline. NASA officials said they were confident they could hit 2024, but the astronauts who will make that first moon landing in half a century—on a mission designated Artemis 3—might have to settle for a limited version of the xEMU if significant issues arise during testing.

In an interview a few weeks later, Hansen and his colleague Jesse Buffington, NASA’s Exploration EVA system development lead, were more optimistic. They have plans for the full xEMU to be ready for the 2024 landing, with a flexible lower torso assembly rather than a rigid one, for enhanced mobility during a moonwalk.

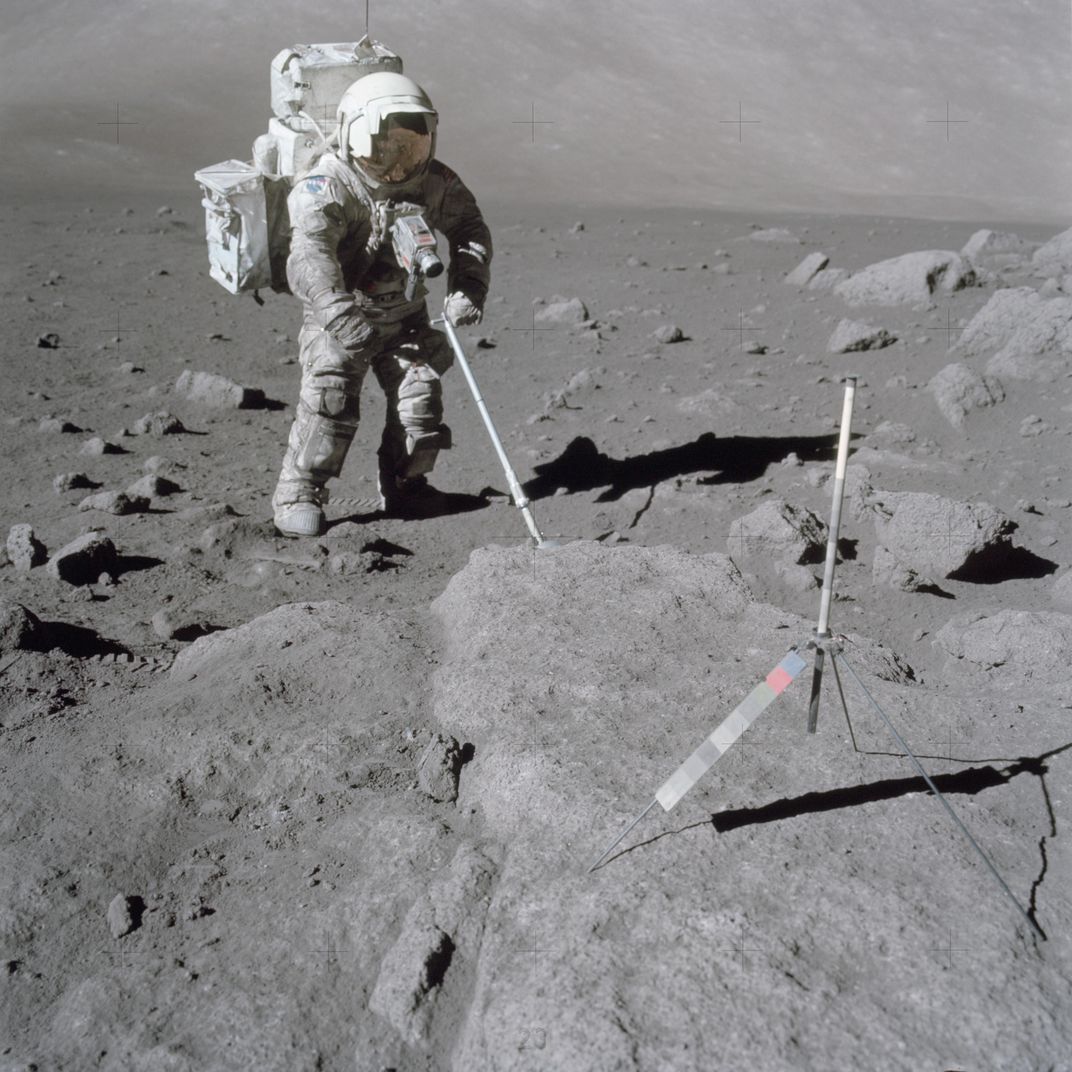

That’s a key design goal for a 21st century spacesuit. Today’s EMUs have some flexibility in the arms and hands, but not in the legs. That’s not much of a problem when floating on a tether outside the space station, but for the moon, leg mobility is a high priority. Reaching down to pick up a rock was a major undertaking for the Apollo astronauts. It sometimes required dropping to their knees, grabbing the sample, then pushing themselves back up. Falls were not uncommon.

The xEMU’s lower torso assembly has at least two bearings per leg, to allow for some movement and bending—technology advanced in the Z-2 experimental suit developed for NASA several years ago by ILC Dover. Walking in such a suit would still have limitations, but it would be a significant improvement over the Apollo experience and would lead to suits with even greater mobility, which could also be adjusted at the shoulder and waist based on the size of the astronaut.

Weight is always an issue with space hardware, so lightweight titanium is being considered for the leg bearings. As usual, there are tradeoffs. While titanium is appealingly light, NASA studies show that it is more prone to wear than steel, a drawback when engineers are aiming for a cycle life roughly 100 times that of current EMU bearings. Titanium also is known to be flammable in reduced pressure and 100 percent oxygen environments, so there has been extensive testing and analysis to make sure it would be safe to use in the xEMU.

Another feature NASA wants in its next moon suit is modularity. The parts of the suit will be designed to work together in a variety of combinations that can be mixed and matched. Commercial providers will have to follow those modular standards accordingly. The Apollo suits, by contrast, were individually (and expensively) fitted, and the current space station EVA suits are made from two large pieces.

Modularity will also come in handy when the suits are adapted for other missions, like Mars exploration. “What we come back to frequently is the question ‘What should a spacesuit look like to go wherever we might want to go,’ ” says Hansen.

The new moon suits are designed to be entered from the back, rather than having the astronauts lower themselves into the bottom half at the waist, then put on the top half, as they have done since Apollo. Russian spacesuits have been rear-entry for decades, and NASA now agrees that is preferable. That was in fact something the agency learned from research done under the Oceaneering contract.

The next-generation suit will allow for longer EVAs, beyond the roughly 6.5-hour limit of current spacewalks. A key to meeting that goal is to have a life support system that can scrub out carbon dioxide and water more efficiently than current systems can. One promising approach is the rapid cycle amine system, which removes carbon dioxide and humidity, and, unlike today’s lithium hydroxide scrubbing system, is regenerated during a spacewalk.

As a general approach, NASA wants to build redundancy into the suit’s life-support system. The new moon suit also will have digital communications befitting an Internet-era astronaut, and electronic displays may replace Apollo’s printed checklists. The “Snoopy Cap” and old-fashioned microphones will be replaced by an integrated communication system mounted inside the suit.

Astronauts working on the lunar surface will need to be better protected from dust than were the Apollo moonwalkers. Minerals in the lunar soil include tiny glass particles that can erode fabric. The dust is sticky and gets everywhere. Understanding the dust problem and how to mitigate it is therefore among the spacesuit engineers’ highest priorities.

The Apollo suits had a variety of protective layers, but the dust found ways to make it through the weave as well as most everything else. Gene Cernan, the last person to step onto the moon, put it this way in his Apollo 17 debrief: “You have to live with it but you’re continually fighting the dust problem both outside and inside the spacecraft. …You can be as careful in cleaning up as you want to, but it just sort of inhabits every nook and cranny in the spacecraft and every pore in your skin.” One active area of study is how and where the dust got into the Apollo suits; often it was at the glove-arm connection, zippers and other junctions.

As an alternative to fabric suits, outer shells are being tested that are highly flexible and durable, using materials that didn’t exist in the 1960s (and are held as proprietary secrets by their inventors).

Another idea for beating the dust problem—not focused on the suit—is to redesign the airlock system astronauts will use to transfer between their lander and the lunar surface. Engineers have also looked into an integrated “suitport” attached to the lander. Astronauts would enter the suits from behind, detach, and walk right out onto the surface.

Spacesuits are sometimes described as the world’s smallest spacecraft—vehicles built for one. Right now they come in only three sizes: medium, large, and extra-large. Today’s space station suits were made primarily with male astronauts in mind. (A smaller suit was discontinued in 1992.) But even before NASA decreed that the Artemis 3 lunar landing crew will include a woman, that size constraint was a problem.

The issue made a splash last March when NASA announced that, for the first time, two women would be making a space station EVA together. That contingency had never been planned for, and it soon turned into a problem. When it was learned that only one medium suit was in good enough shape to be used, the idea of an all-female spacewalk had to be quickly (and with some embarrassment) scrapped.

It was ultimately astronaut Anne McClain’s decision to step down and give to a male colleague the spacewalk she had been assigned. Judging from her own past spacewalking experience, she believed that she wouldn’t perform as well in a large, rather than a medium, suit.

It’s now generally accepted that a wider range of suit sizes has to be made available, especially for women. The training and flight experiences of retired astronaut Catherine “Cady” Coleman demonstrate why. At 5 feet, 4 inches, Coleman was one of the shortest astronauts of her generation (although Yuri Gagarin was two inches shorter). She and other women of similar stature were able to do their jobs in space, but not without some jury-rigging of their spacesuits.

As Coleman explains it, she was able to wear a medium suit, but there was a lot of extra room—too much. She consulted female former astronauts to learn how they had dealt with similar situations, and was told about packing the suit with foam rubber. The space gloves were also too large for her hands, and a new pair had to be made for her. But they didn’t work either, and she experienced numbness in her hands for months. The pain sometimes still returns.

Coleman is an ardent supporter of human space exploration, but she says future suits absolutely must be made with the changing astronaut corps in mind. Spacesuits, she said, are “the gatekeepers” for who will be future space explorers and what they will be able to do.

Hovering over the advanced spacesuit research program—and the entire Artemis enterprise—is the ever-present question of whether today’s ambitious lunar plans will remain a priority for NASA. EVA officials say their work on a modular suit can still progress, but before long they’ll need specifics: How many astronauts will land in 2024 (the current plan is at least two), and where exactly will they land? How many spacewalks are required? How much power will be available? How heavy can the suits be, and where and how will they be packed inside the lunar lander? The engineers will need those answers and more, and they’ll need them soon.

Only recently has NASA even hinted at a total price tag for the Artemis program—in the $20 billion to $30 billion range over five years, according to administrator Jim Bridenstine. That would be in addition to the agency’s current annual budget of $21.5 billion. Hansen of the EVA Office says that spacesuits are expected to get less than five percent of that—between $1 billion and $1.5 billion over a decade, depending on how the schedule unfolds.

He and others in the agency embrace the need to demonstrate real progress in the near term, and to no longer simply talk about the moon and Mars as goals for the future. “The public has to see us fly,” he says. “We just have to show tangible results. Then, as soon as we start going back to the moon, we think the support will come publicly and politically.”

And along the way, a new and better spacesuit just might be born.