A 747 for Star-gazing

How engineers altered a jumbo jet to carry the world’s biggest airborne telescope.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Major-Surgery-FLASH.jpg)

On several nights this winter, in the frigid stratosphere over the Pacific Ocean, the pilots of a dramatically modified Boeing 747SP will relinquish control of the aircraft, and astronomical mission controllers will take over, steering the jumbo jet westward along a slightly curved star-tracking course at 520 mph. In the former passenger cabin where rows of seats used to be, two dozen astronomers and technicians at computer workstations will sit poised for an event unprecedented in the history of aerospace.

At a computer command, a giant door in the rear fuselage, just behind the wings—a door nearly as wide and half again as high as one on a two-car garage—will open the aft left side of the aircraft, exposing an enormous cavity to the rarefied atmosphere. Inside this cavity, a reflecting telescope with a mirror nearly nine feet across will point toward an invisible celestial object and gather its light at far infrared wavelengths, while just feet beyond the telescope’s end, air will whip past at nearly the speed of sound.

This airborne observatory is SOFIA, the Stratospheric Observatory For Infrared Astronomy. SOFIA is a joint creation of NASA, which oversaw the extensive modification of the aircraft, and the German Aerospace Center DLR, which managed the construction of the telescope, the largest ever borne aloft. The 2.7-meter telescope is bigger than NASA’s famed 2.4-meter Hubble Space Telescope, and even bigger than the 100-inch (2.5-meter) Hooker reflector atop Mount Wilson, California, which reigned as the largest telescope in the world from 1917 until 1948 (when it was surpassed by the 200-inch Hale on Palomar Mountain in San Diego County).

SOFIA also is an unparalleled undertaking in aircraft modification. The aircraft is flying with a hole in its side that extends nearly a quarter of the way around the circumference of the fuselage; the telescope cavity door is not a structural component. Just how was the 747SP reconstructed so that, absent a quarter section of its fuselage, it could withstand normal aerodynamic loads and buffeting at Mach 0.85 without the tail twisting off?

IT WAS IN THE EARLY DAYS of NASA that astronomers conceived of flying a telescope in the stratosphere to observe the universe at far infrared wavelengths. Across a broad swath of the electromagnetic spectrum, from visible light to wavelengths measured in millimeters (1,000 micrometers), astronomers are effectively blind: Atmospheric water vapor blocks much of the infrared radiation from reaching Earth. To be sure, cryogenically cooled detectors on telescopes at mountaintop observatories can observe short infrared wavelengths, such as heat radiation. But even at the highest and driest locations, such as in Chile’s Atacama desert, residual atmospheric water vapor precludes observations in most of the far infrared.

An aircraft flying in the stratosphere, however, is above 99.8 percent of the vapor. The stratosphere’s dry cold (as low as –60 degrees Fahrenheit) can keep the entire structure and primary mirror at cryogenic temperatures without condensation or frost, although liquid nitrogen is needed when the airplane is on the ground just before and during takeoff to pre-cool the telescope to stratospheric temperatures before the cavity door is opened. Unlike a spacecraft, an aircraft periodically returns to earth; when it does, its cryogenics can be replenished, so an airborne observatory has a lifetime as long as that of the aircraft itself—about 20 years or more. (Most space-based infrared observatories don’t last as long; the Spitzer Space Telescope, for example, was launched in 2003 and ran out of cryogenics in 2009.) And unlike a ground observatory, an airborne one can be flown anywhere in the world for the best view of important celestial events.

In the early 1960s, NASA modified and flew several aircraft carrying telescopes to observe in the infrared; the last was the Gerard P. Kuiper Airborne Observatory (KAO), a modified Lockheed C-141A Starlifter carrying a 36-inch reflector. From its first science mission, in 1974, the KAO, operated from NASA’s Ames Research Center at Moffett Field, California, revealed the structure of Pluto’s atmosphere, the gas and dust between stars, and stunning cosmic processes involved in the birth of stars. It also discovered rings around Uranus.

The infrared marvels it revealed were so exciting that “astronomers immediately began wondering what they could do with a telescope that could collect roughly 10 times more light,” recalls Edwin Erickson, KAO’s facility scientist at Ames and later SOFIA’s first project scientist (now retired). Erickson described the potential of such a telescope in a 1980 paper, and by January 1986, Ames had established a SOFIA study office. Over the next decade, Ames scientists tested models of several open-port designs in wind tunnels. In 1995, NASA decommissioned the KAO so its budget could be applied to the full development of SOFIA, which began in 1996.

“As a replacement for the KAO, the science community wanted the largest possible telescope that could be flown on the largest possible aircraft at 41,000 feet or higher for as long as possible,” says Ames’ Nans Kunz, SOFIA chief engineer from its inception until 2007. Like a family on a budget shopping for the best used car, NASA was restricted by its funding to a used aircraft. SOFIA’s basic mission specs immediately narrowed the aircraft candidates to a handful of then-available military cargo planes and large commercial airliners. After scientists compared the finalists for fuselage size, weight-carrying capability, and ability to cruise for hours at high altitude, the hands-down winner was a Boeing 747 jumbo jet. The 747 had a record of reliability in commercial service, readily available spare parts, and an estimated lifetime of at least another 20 years.

Most promising was the unusual short-body 747SP, or Special Performance model, produced in the 1970s and 1980s. Only 45 were built, primarily for airlines wanting to offer long-range, nonstop service between cities nearly half the globe apart, such as New York and Tokyo. The 747SP has the same engines and wingspan as a full-length 747-100, and carries the same amount of fuel, but it is 48 feet shorter, making it lighter and thus longer in range. To compensate for the handling changes that shortening the fuselage produces, designers made the 747SP’s tail two feet taller and 10 feet wider than a standard 747’s.

THE SINGLE BIGGEST AERODYNAMIC CHALLENGE NASA engineers faced was modifying the airplane so it could fly safely even with an enormous hole in its fuselage. That challenge broke down into several key imperatives, notably: not disrupting clean airflow over the fuselage and control surfaces; restoring the strength and stiffness of the fuselage after structural members were removed and a heavy telescope assembly was added; and minimizing acoustic vibrations.

Plenty of airplanes open doors in horizontal flight—to release bombs, parachutists, or cargo. But they don’t continue to fly with open cavities for eight to 10 hours at a stretch, they typically don’t fly in the stratosphere, and they certainly don’t fly with a door as big as SOFIA’s. This telescope’s cavity is so huge in proportion to the size of the aircraft that the aerodynamic challenges in designing it were “in a different universe [from the KAO],” says former project director Ken Szalai of NASA’s Dryden Flight Research Center at Edwards, California.

Even to the untrained eye of a visitor walking around the outside of the aircraft, as I did last March at the 747’s new home in Palmdale, California, the scale of the challenge is startlingly evident. The full cut-out measures 14.5 feet wide and more than 16 feet circumferentially—although only about half of that circumference is exposed in flight because a rigid upper door and a lower flexible door (like the front of a roll-top desk) slide in tracks to follow the 22-ton telescope’s aperture as it points high or low. “It’s the largest cavity we’re aware of that’s ever been flown,” says Robert Meyer Jr., a former flight test crew member who is now SOFIA program manager at Dryden.

The cavity for the KAO’s reflector was forward of the C-141A’s wing and right behind the pilots, in what on a commercial flight would be first class. But in SOFIA, “the telescope flies economy,” quips Erickson, because a far aft position for such a large open port reduced engineering complexity and expense. Only a third of the control cables—those for the tail—would need to be rerouted around the unpressurized and unheated telescope cavity. Most crucially, an aft position minimizes the chances of high-speed, energetic air dipping down into the cavity and creating destructive acoustic resonances—literally tones. “Think of blowing across the open top of a Coke bottle to make it hum,” says William Rose, who made open-cavity aero-optics and aero-mechanics improvements for the KAO at Ames and now as president of Rose Engineering in Nevada is doing similar work for SOFIA. The cavity was placed at the rear of the aircraft to keep it away from the most highly compressed and highest energy airflow—around the nose of the vehicle, the forward fuselage, and the wing leading edges.

The task of modifying the airplane was contracted to what is now L-3 Platform Integration in Waco, Texas. “We were brought in because we make heavy aircraft mods. We don’t touch anything smaller than a C-130,” says Greg Bruich, technical director for SOFIA’s mission controls and communications system from 1995 through 2003. (During the creation of SOFIA, the company was acquired and changed names four times—from Chrysler Technologies Airborne Systems to E-Systems to Raytheon Aircraft Integration Systems to L-3—so NASA personnel “took to calling it just ‘Waco,’ ” Nans Kunz says.)

First, L-3 had to reverse-engineer every aspect of the aircraft’s existing design. The 747SP was designed in the late 1960s, long before the days of computational fluid dynamic models. Sure, Boeing had aircraft drawings, specifications, and analyses, but NASA needed a detailed structural model of the airplane to understand how loads were carried through the structure. “So we covered the unmodified aircraft with 350 strain gauges and other instrumentation, and then collected data as we repeatedly put it through wind-up turns, side slips, and other baseline maneuvers to measure loads on fuselage, wings, and tail,” recalls Albert Ruggles, L-3’s lead structures analyst for SOFIA. From that data, the L-3 engineers painstakingly built a computer model that represented every frame, sill, stringer, and other structural member—some 150,000 elements in all. The model gave the engineers a powerful tool to plan SOFIA modifications and simulate how various configurations would affect structure and aerodynamics.

For one thing, the engineers needed to model what would happen when the telescope cavity left only three-quarters of the fuselage holding onto the tail. A quick try-this-at-home experiment reveals why: Wearing gloves, grab the ends of an empty aluminum soda can in both hands and try to twist it. As thin as the aluminum is, it resists a surprising amount of force. Next, cut a square hole in the can that extends a quarter of the way around the circumference. Now, crumpling the can takes far less twisting force. Why? “The skin of an airplane is more than just a big balloon with ribs that holds in the cabin air pressure,” explains Dwight Doty, L-3’s engineer in charge of aerodynamic analysis. “The airplane’s fuselage is a semi-monocoque construction, meaning the skin is mounted to an underlying skeleton. The skin carries pressure and shear loads—that is, forces that would tend to stretch, compress, or twist the fuselage—and distributes these loads to the stronger skeleton.”

Even with the cavity door closed, I could clearly see that the door and the tracks along which it runs make part of the fuselage asymmetrical, raising the aft left side a bit and making it more cylindrical. The asymmetry in turn changes the airflow, stresses, and structural loading on the rest of the airframe. Moreover, Doty adds, with all the telescope’s weight concentrated in the back, “this structure is not loaded like a regular aircraft.” Thus, L-3 needed to calculate how to redistribute strength, stability, stiffness, and shear stresses around the telescope cavity by strengthening the underlying skeleton structure, which is made up of hoop-like frames encircling the fuselage, longitudinal beams, and other internal supports. The engineers also needed to thicken the skin itself. “Some places right around the cavity [now] have several skin layers totaling more than half an inch thick,” Doty points out.

The interior of the telescope cavity also had to be mathematically modeled. When the doors on most bomb bays, or even on the KAO, open, the airflow is disturbed, causing the airplane to shake noisily. With SOFIA’s huge cavity, design engineers did not want shaking. Worse, says Kunz, “we didn’t want a 747-sized organ pipe.”

Under the right conditions, all cavities resonate acoustically, just like a musical wind instrument. “We were really concerned about organized tones,” said aero-acoustics expert Rose. “You can’t have that, because structures can be torn apart by pressure changes.” The amplitude—or loudness—of the pressure variations changes with the square of the speed; the pressure fluctuations at 500 mph are 100 times greater than those at 50 mph. If fluctuations of that magnitude happened in a car with a window down driving at freeway speeds, “blood would be running out of your eardrums,” says Rose. Such powerful vibrations would “quickly eat up the fatigue life of the aircraft’s metal structure in a matter of minutes, not hours,” says Dryden’s Meyer.

Because mathematical modeling is less reliable for unsteady airflow than for, say, structural loads, the team collected data from wind tunnel tests on a 7-percent-scale model. “We knew we had only one shot at modifying the real thing,” says Doty, “so we bought another Section 46 from a sister 747SP from an aircraft storage yard in Oklahoma to practice on.” Section 46, the fuselage segment between the wing and tail, is the part that would hold the telescope cavity and new pressure bulkhead (separating the heated and pressurized crew and astronomers’ cabin from the unpressurized telescope cavity). L-3 flew the section back to Waco in NASA’s Super Guppy transport.

L-3 did not saw a hole in the side of the 747SP. Instead, engineers removed structural elements and panels and replaced them a few at a time, while taking an approach analogous to shor¬ing up the walls of a house before digging a new basement. Ruggles says that for the modification, “the plane needed to be in traction, so we put it in jig position,” a term for supporting the aircraft so there are no loads anywhere on the structure.

Once the aircraft was in position, Ruggles says, “we started by installing as much of the new skeleton first before taking out the old skeleton.” The installers first replaced frames, stringers, and other supporting members with beefed-up versions, then removed the originals. Same for the skin: on with the new, off with the old. At the telescope cavity, says Ruggles, “off came a regular panel, on went a panel with part of the cutout.”

After finishing the modification, the engineers faced a trial that was more challenging emotionally: giving the reconstructed airframe a “proof pressure” test by inflating it to 12.5 pounds per square inch (psi), 33 percent above maximum operational cabin pressure, to prove it could be safely pressurized in flight. “At first we heard a few light pops as skin panels pillowed out,” Ruggles recalls. “Then at about 12 psi, suddenly a loud bang made us all jump. But it turned out only to be severe thunderstorm winds slamming a door behind someone.”

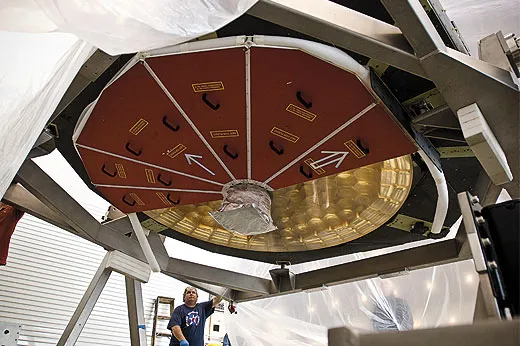

WHILE L-3 WAS MODIFYING THE AIRCRAFT in Texas, the German DLR center was overseeing construction of SOFIA’s telescope in Bonn, Germany. The instrument was built primarily by MAN Technologie AG and Kayser-Threde GmbH. After being integrated and tested in Augsburg, the telescope was disassembled and shipped to Waco in a Beluga (Airbus A300-600ST Super Transporter). A crane gently lifted each major subsystem and lowered it into the modified aircraft’s telescope cavity. “It barely shoehorned into the opening,” Doty recalls. “It was a remarkable feat—almost like giving birth in reverse.”

In May 2007, after some significant structural test flights at L-3 were completed, SOFIA flew from Waco to Dryden for interior completion. In January 2008, the flying observatory was relocated to the new Dryden Aircraft Operation Facility in Palmdale, about 40 miles from Edwards, which allows easy access for non-NASA and international personnel. Dryden will oversee SOFIA’s flight operations even after SOFIA program management moves to the SOFIA Science Center at Ames.

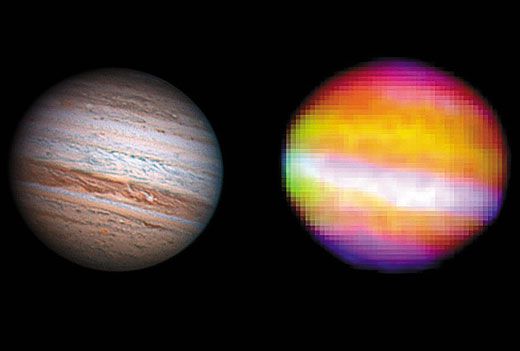

On December 18, 2009, SOFIA passed a major aerodynamic milestone: a daytime test flight with the telescope cavity door fully open, all under the watchful eyes of chase planes and ground cameras. And on the night of May 25-26, 2010, SOFIA passed a major astronomical milestone: while airborne at 35,000 feet, the telescope achieved what astronomers call first light, taking a look at both Jupiter and the galaxy Messier 82.

Both achievements were huge moments for NASA, L-3, and the German Aerospace Center. “If compared to human surgery, that aircraft went through the equivalent not just of a heart-lung transplant, but also replacing your liver, kidneys, and part of your brain,” says Ken Szalai. SOFIA has run far beyond NASA’s originally projected schedule and budget; its current development cost, $1.1 billion, is about triple the budget NASA originally projected in 1997. But Szalai is not bothered: “In doing something this close to the edge of the unknown, there is nobody who could accurately estimate it,” he says.

Last summer, the SOFIA Science Center announced the first 75-hour block of observing time for basic research between March and August 2011. The center received 59 proposals from 31 institutions for more than triple the number of observations that can be made during the first block of time.

Trudy E. Bell is a former editor at Scientific American.