Bigger Than Saturn, Bound for Deep Space

Part space shuttle, part Apollo, the Space Launch System will be the most powerful rocket ever built. Will it be the best?

:focal(699x393:700x394)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/b2/68/b268b300-716e-4cec-8bec-ca552f5144bf/05y_on14_bbb_opener-1.jpg)

On a tour of the Aerojet Rocketdyne assembly building at NASA’s Stennis Space Center in southern Mississippi, site manager Mike McDaniel stops at a double row of shrouded shapes and big white metal boxes inside a garage-like room. In each is an RS-25, the space shuttle’s main engine. With the exception of one more engine to be assembled from spare parts, the room we’re standing in holds the entire world supply—15 in all—of flight-proven, reusable big booster engines. While the value is hard to calculate, given that production lines for replacement engines haven’t restarted, there’s certainly more than a billion dollars’ worth of hardware tucked into a space no bigger than a 7-Eleven.

The engines are critical to NASA’s next plan for human spaceflight and illustrate an important principle guiding the design of the nation’s next booster: Rather than reach for advances in rocketry, engineers are to use proven technology. The RS-25 engines, which performed almost flawlessly during 135 shuttle launches, are a gold standard for reliability and power that NASA wants to preserve, even after the small inventory is used up. Yet the last enhancement to the engines was made in the 1990s, and the new launch vehicle—uninspiredly named the Space Launch System—is expected to be the first one capable of sending humans beyond the moon. The contradiction between its design constraint and its ambitious mission puts engineers like McDaniel in a tough spot. They are using space shuttle hardware for a vehicle tasked with a human spaceflight mission far more daunting than putting astronauts in orbit around Earth. But you won’t hear complaints at Stennis, where the engines are tested, or at Marshall Space Flight Center in Huntsville, Alabama, where the SLS program is managed.

“We had a school group in here one day to see the engines, and a girl raised her hand,” McDaniel recalls. “She said, ‘There are supposed to be 15 here but I only count 14.’ That’s the kind of person we want in this program, who doesn’t take things for granted.”

Little is taken for granted with the SLS, given the fate of its predecessor, the more imaginatively named Ares I rocket, which didn’t get very far. Ares made a single test launch in 2009 before the Obama administration cancelled the human exploration program—Constellation—which required a big new launch vehicle for missions to the moon. But the SLS borrows certain features from the Ares I rocket, including a new digital engine controller and the use of shuttle-era solid rocket boosters.

NASA and Congressional supporters are determined to have the Space Launch System ready for its first launch in December 2017, seven years after NASA got its orders from Congress to build a new heavy-lift rocket for deep space. At a glance, the rocket will have a classic profile, reminiscent of a launcher even older than the space shuttle: the Saturn V. Like Saturn, each SLS booster will fly just once, then be discarded. In its first phase, the launch vehicle will have a payload capacity of 77 tons and stand 321 feet—not quite as tall as the Saturn V but delivering 10 percent more thrust. It will grow through the 2020s to support missions that will be gradually more ambitious. The final version, called Block II, will tower nearly 400 feet on the Mobile Launch Platform—40 feet taller than the Saturn V, with 20 percent more thrust. Capable of carrying 143 tons to low Earth orbit or a crew to Mars, it will be the most powerful rocket ever built.

As with the Saturn, the SLS will be topped with a conical capsule for manned flight, called Orion (see “America’s Next Spaceship,” Aug. 2014). But down lower, the Space Launch System has more visibly in common with the space shuttle, with two solid rocket boosters strapped to its sides. The rocket’s first stage (which NASA calls the core) is a stretched version of the shuttle’s external tank and has the same diameter, so that shuttle-era tooling can be reused. At the base of the core are four space shuttle main engines (SSMEs). It will use a single upper stage to boost Orion into deep space.

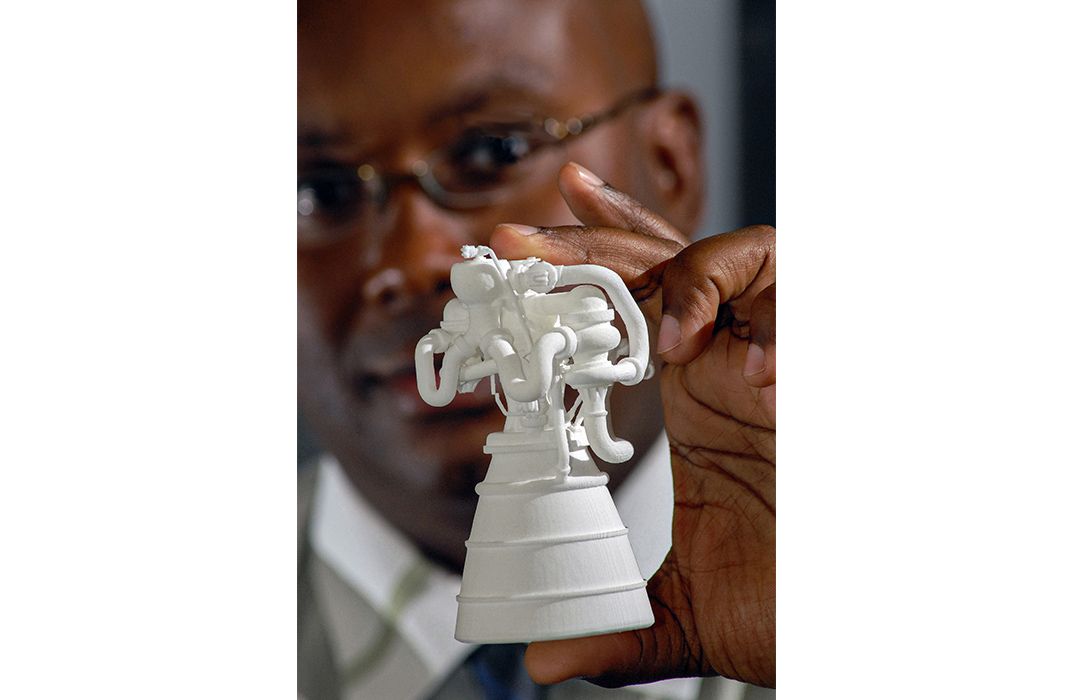

A number of technologies that hadn’t been developed when the shuttle was designed, such as stir-friction welding for the SLS core and 3D printed parts for Orion, does push the SLS beyond the shuttle’s world. “This is brand-new, modernized equipment, resulting in much more reliability and capability at much less cost,” says Charlie Precourt, a former shuttle commander and today vice president and general manager of ATK, the solid booster manufacturer. At ATK, he says, workers are adding a fifth segment to give the solid rocket booster more capability. Precourt says the work will be done using only one-fourth the number of employees required during the shuttle era.

A multi-purpose, disposable vehicle, the SLS is sure to be expensive, but just how expensive is not yet known. Boeing is building two core stages under a $2.8 billion contract. According to budget documents, the SLS program annual cost is less than half that of the shuttle program, which ran to $4 billion annually in its last years. But the shuttle flew successfully 133 times over three decades, and (barring some political sea change) the SLS isn’t expected to launch more often than once every two years. The Government Accountability Office estimated the SLS’s cost through the first launch at $12 billion, and the total tab through 2020 at $22 billion. But in July, the GAO warned that NASA would miss the 2017 launch unless the SLS program gets an additional $400 million.

The first SLS mission is a test. It will send an unmanned Orion capsule looping far around the moon, then back to Earth for a splashdown. The second mission? Less firm. While some House members are urging that the second mission send a robot probe to explore Jupiter’s moon Europa, which may harbor life beneath its frozen surface, NASA’s current plan is to carry astronauts to visit an asteroid orbiting the moon. (A separate robot spacecraft would go out first, grab the rock, and haul it into lunar orbit.)

Critics like former NASA deputy administrator Lori Garver see the SLS as a red-tape-ridden reminder of Old Space from top to bottom. By the time NASA uses the SLS to go to Mars, Garver has said, astronauts will be going there on “50-year-old technology.” New Space could do better, she and others, like Congressman Dana Rohrabacher of California, say, pointing to newcomers like Elon Musk’s Space Exploration Technologies (SpaceX), which has used its Falcon 9 rocket for low-cost launches of cargo to the International Space Station and satellites to high orbits.

SpaceX is already planning a heavy-lift Mars-capable rocket that would rely on a radically more powerful and sophisticated engine called Raptor, which would burn liquid methane rather than the standard hydrogen or rocket-grade kerosene. It’s a bit of a long shot for Musk; SpaceX has never built an engine so powerful or efficient, nor has any nation’s space program put methane-fueled rocket engines into production.

SLS managers don’t have the time or the money to pursue exotic technologies or big leaps like methane-fueled engines. To be fair to the pocket-protector crowd, it’s not for lack of far-out thinking. NASA archives hold heaps of plans for cool gadgets like an aerospike engine and nuclear-thermal rocket. Today’s dialogue is less about innovative gizmos and more about how space spending has become a zero-sum game, to the point that even strong space advocates have divided into bitter factions, fussing yearly over whatever scarce dollars are available.

There are three camps. The first puts their hopes in the traditional NASA/contractor partnership and supports the NASA-designed SLS as the best way to keep the man-in-space dream alive. This is championed by a majority in Congress. The second is led by President Obama and charismatic business leaders like SpaceX’s Musk, who believe that the private sector should take the lead role in building and flying boosters for manned space, first into low orbit, and eventually to Mars. The third worries that the traditional “bucks for Buck Rogers” focus on human-rated boosters for the space station and Mars is draining the lifeblood from scientifically productive work, such as a robotic mission to Europa. Although cheaper than any human-led alternative, such one-off robot missions still cost billions and take years to develop. And, depending on the location, also take years to deliver.

NASA still has visionaries in its ranks, and their eyes are on the SLS. “We’ve been spending all our time in low orbit. That’s just 220 miles up,” says Chris Crumbly at Marshall, who is in charge of lining up scientific missions for the SLS’s early years. Crumbly says that an SLS-boosted mission would get to Europa in just two years, rather than the seven an Atlas V rocket would require. Missions now cruising deep space, such as New Horizons on its way to Pluto, had to pare back on payload because their launchers simply couldn’t haul any more weight.

But using the SLS for missions to the outer worlds, or in fact anywhere in deep space, will require deep pockets. “The problem with the SLS is that it’s so big—that makes it very expensive. It’s very expensive to design. It’s very expensive to develop,” former Mercury, Gemini, and Apollo flight control chief Chris Kraft told the Houston Chronicle last year. “When they actually begin to develop it, the budget is going to go haywire.” The SLS, though, has powerful supporters in Congress, such as Senators Richard Shelby of Alabama and Bill Nelson of Florida. Shelby told the Huntsville Times last year that he would “continue to fight hard to ensure that taxpayer dollars are invested wisely in SLS so that we maintain our nation’s leadership role in human spaceflight.”

As NASA sees it, the SLS is precisely the sort of vehicle the country needs post-shuttle, for a variety of missions. “We’re not building a one-of-a-kind spacecraft,” says William Gerstenmaier, NASA associate administrator for human exploration and operations. “We’re building hardware that can satisfy multiple needs. There’s real work moving forward. This is no longer a paper program.”

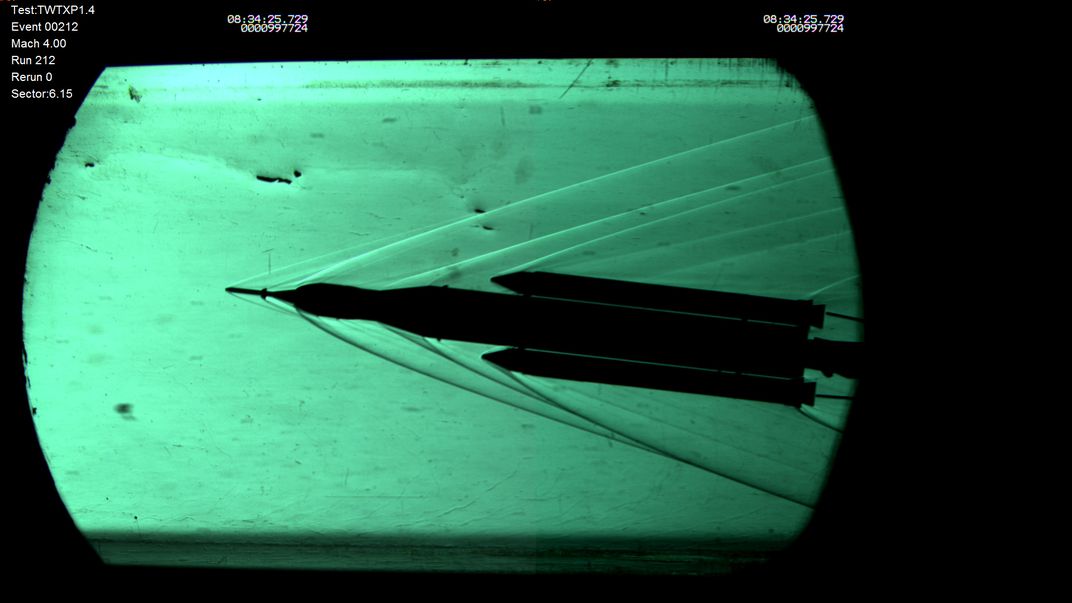

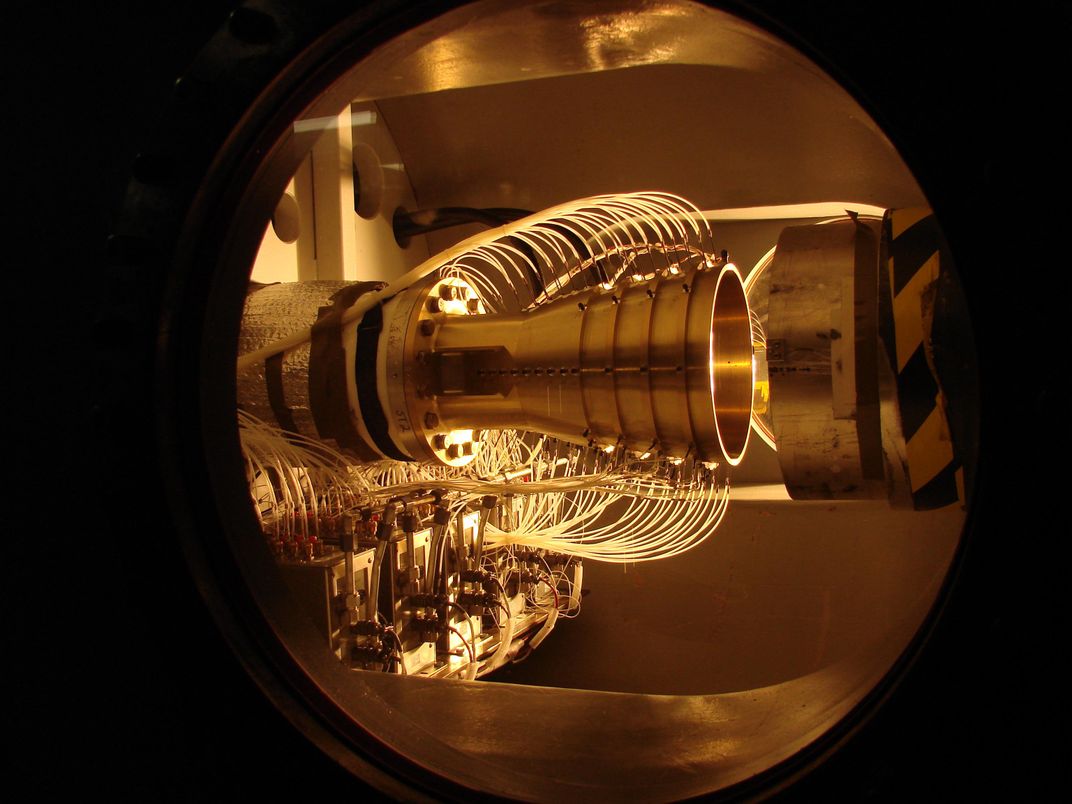

Those 15 SSMEs at Stennis are the most significant pieces of hardware that have helped the SLS move quickly beyond the paper stage. They were tested and improved throughout the 30 years the space shuttle flew. The first-generation SSMEs were “early in staged-combustion, and we were very close to the material limits on everything,” says NASA’s Mike Kynard, who recently retired as manager of liquid engines for the SLS at the Marshall Space Flight Center.

The engines that replaced the original models are more powerful. “At one million seconds [of run time] and 3,000 starts, we know it up one side and down the other,” he says. With turbopumps operating at 37,000 rpm, each turbine blade in the pump—though no bigger than a postage stamp—has to produce 600 horsepower. As reusable engines with proven durability, they would have been capable of supporting many more shuttle launches, but on the SLS, these high-performance machines will be used just once then dropped into the Atlantic with the rest of the core stage and the strap-on boosters. (Unlike in the shuttle era, the strap-ons won’t be reused.)

“It’s a misuse of those engines,” says J.R. Thompson, a former director of Marshall who went on to head Orbital Sciences Corporation, which also delivers cargo to the space station. Thompson, now retired, was a key manager during the early years of SSME development—a soul-trying period that saw 13 engines burn up or blow up during ground tests before 1983. “I am not a fan of SLS,” he tells me over breakfast in Huntsville. “It has no mission. It costs way too much. It’s driven by political decisions. It’s a job program. In my view, there’s no enthusiasm in the country for it.”

One private nonprofit is trying to boost enthusiasm for the SLS as the most practical way to reach Mars soonest. The Inspiration Mars Foundation asked NASA to aim for a 2021 launch window. “It’s a good thing the SLS is being developed,” says Taber MacCallum, the foundation’s chief technology officer. “I didn’t frankly start off as an SLS supporter in this, and I came around to being one.”

Both Stennis and Marshall space centers are all in. Other engines besides the flight-ready SSMEs will play a part in preparations for the Space Launch System’s first launch. One that Stennis facility director Mike McDaniel shows me in the hall is a non-flight SSME to be used for ground tests this fall. The point of those tests will be to prove out the new digital engine controller. At Marshall, engineers show me that particular piece of gear in the Hardware Simulation Laboratory. An engine controller is a suitcase-size computer that nestles alongside each engine, monitoring vital signs and tweaking valves, and generally keeping the engine from the point of self-destruction.

On our walk-through of the lab, deputy liquid-engine manager Tom Byrd points out the grayish, original controller from the shuttle era; it used the same processor as an Apple IIe computer. The new controller has modern electronics because it was developed in 2009 for Constellation-Ares. It’s also half the weight and half the cost of the old one. NASA is in the

process of moving tests for it from the safe confines of the Hardware Simulation Laboratory to Stennis’s Test Stand A-1 in order to ensure the electronics will work under heat, noise, and vibration.

Byrd, who joined NASA in 1983 and retired last summer, watched the Constellation program founder, and now sees the SLS as critical to NASA’s future and to the aerospace industry at large. “Within five years, we’ll have thousands of people eligible to retire from NASA. It’s a huge number, about 40 percent of the workforce. So we need a lot of replacements, and they need a flagship program to sink their teeth into,” he says, echoing J.R. Thompson’s opinion of the SLS as a jobs program.

At Stennis, in less than two years, a derrick crane atop the otherworldly complex called B Stand will whir to life. It will swing over an adjacent canal, pluck the SLS core off a barge arriving from Louisiana’s Michoud Assembly Facility, raise it several hundred feet in the air, and inch it down to a very stout fitting. Propellant tanks will be filled to the brim, bolts will be tightened, and NASA will be ready to light the four SSMEs at the bottom of the core for a full-duration burn of nine minutes. If this test goes well, the core will then travel by barge to Florida and join up with solid rocket boosters and the upper stage for a debut at Kennedy Space Center’s Launch Complex 39B a year later.

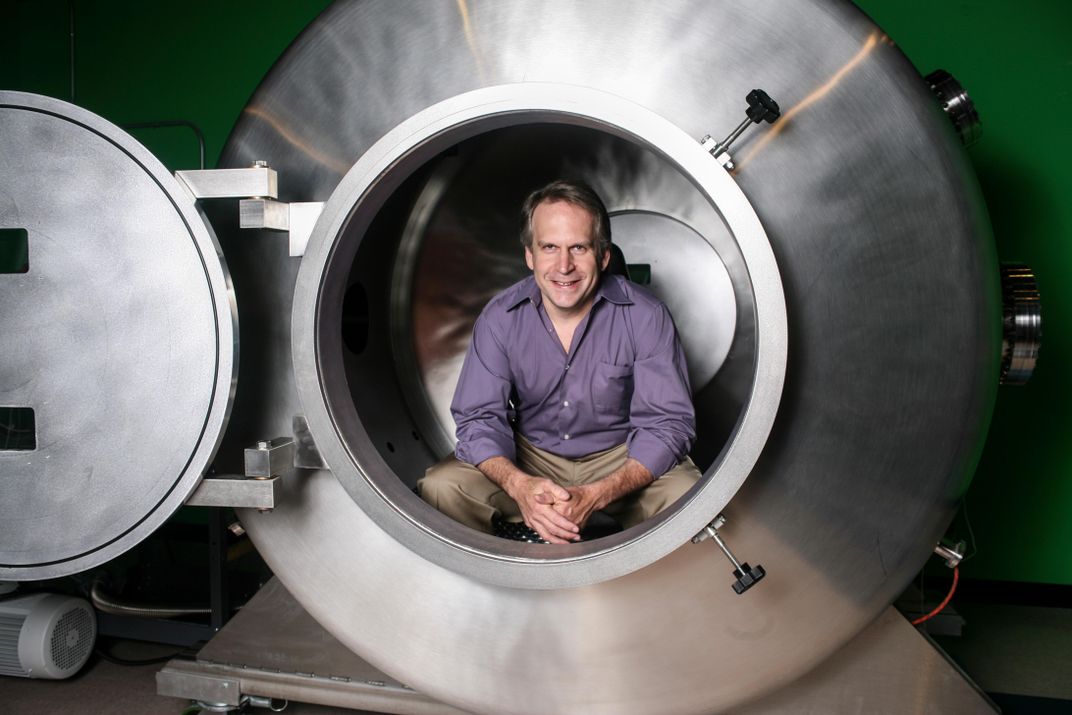

While B Stand is rarely photographed from the shady north side, that angle offers the most striking view. On the outside corners are four flared concrete legs the size of skyscrapers that frame an even larger concrete core. A multitude of girders and thick steel plates brace the engine and channel air flow. There are two stands: B-1 to the west, and B-2 to the east. Underneath each engine mount is a gigantic gray scoop a hundred feet high that tops off at ground level. This is the flame bucket: Every second, 5,000 gallons of water will inundate the area and flow down the bucket to keep the steel from melting under the hydrogen flame. B Stand is a National Historic Landmark because its full-throated, multi-engine booster tests were key to both Apollo and the shuttle. Testing began in 1967, and since then its mission can be summarized this way by engineer Bryon Maynard: “We’d rather make our mistakes here than at KSC. That’s why we test.”

While that core-stage test won’t include the solid rocket boosters, it will be powerful enough to make NASA spend hundreds of millions for a full rehab of B-2—cutting out rusty parts, yanking leftovers from previous tests, and bringing old electronics into the 21st century. As we make our way past a dark corridor called Damnation Alley, Maynard tells me he found graffiti dating to Apollo in control rooms. It’s not hard to get my group of guides talking about the good old days, even those who were too young to participate. “I was watching Mercury on TV at five years old,” says Rick Rauch, lead engineer on the stand restoration. “I knew right then what I wanted to do. I joined NASA in 2000, so it took a while to get here.”

The test stands at Stennis are adaptable to engines big and small, whether of traditional or radical design. One might say that rocket engineers come here in peace for all mankind, even when employed by companies that used D.C. lobbyists to scramble for space dollars. Here rocketeers share the universal language of pragmatism: What breaks and why? What holds up at max power and beyond? How do you know?

Not far from where the SLS engines are tested, Stennis is hosting SpaceX engineers who are checking components for its methane-fueled Raptor. I’m reminded of the manner in which warring tribes of the Great Plains laid down their weapons periodically and gathered at an outcropping of pipestone rock in present-day southwestern Minnesota, where they quarried the soft red stone for spiritual ceremonies back home.

A half-mile from Stennis’ Test Stand A-2, I’m watching a test of what may be the future for the SLS: the Aerojet Rocketdyne J-2X engine planned for use on the SLS’s upper stage. In the last year, NASA has had to shelve development of the engine; it’s being used here only to test the engine controller. The J-2X may yet fly on the SLS, but for the first flight at least, NASA plans to use a cryogenic upper rocket stage, powered by the Aerojet Rocketdyne RL10, which was used on United Launch Alliance’s Delta IV booster.

“Our goal is to bring engine costs down by half, but [retain] the same performance and reliability,” says Mike Kynard. “It’s a budget-constrained environment, so we can’t make wholesale changes. We’ll have to choose between options.”

As the count drops to zero, a mighty flow of water is raising a Niagara-like mist. Through binoculars, the base of Test Stand A-2 has the look of a dam spillway, but it’s part of the flame handling system. Engineer Bryon Maynard taps his wrist: almost time. We check our hearing protection. There’s a wave of chest-thumping noise that shakes the steel railings and decks of our perch. Propelled by blue-white fire, clouds billow from the rocket engine and move north. At 150 tons of thrust, the J-2X engine mounted in the stand, if unleashed, would heave three loaded semi-trailers into the air.

NASA will need that much power if it ever decides to evolve the SLS into its largest configuration for trips to Mars. Meanwhile, the biggest problem for the SLS is less technical than political: In the coming decades will there be enough politicians willing to support such an expensive space beast? Or will historians eventually class it with the one-flight Soviet shuttle Buran? Will the SLS be reserved for politically charismatic missions such as putting boots on Mars, or can it boost robot voyages as well? With the first crewed mission not expected before 2021, there’s time to work out mission goals and the manifest. If the schedule and the will hold, NASA will have something it’s never had before—a system capable of slinging humans, habitats, and robot explorers far beyond the moon and into deep space.