Distance Runners

Unmanned aerial vehicles redefine the term “nonstop flight.”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Distance_Runners_0911_3_FLASH.jpg)

AT SOME POINT in early 2014, Pat O’Neil and Carol Wilke expect to launch a new airplane they hope they will never see again—at least not for a long time. The longer, the better. Initially, the two engineers from Boeing’s Phantom Works want the unmanned aerial vehicle (UAV), named SolarEagle, to fly at twice the altitude of cruising airliners for 30 days straight. Ultimately they want it to stay up for five years, long enough to outlast a presidential administration and who knows how many generations of iPods. They’re so unconcerned about seeing the airplane again, they may have it jettison its wheels after takeoff.

“We don’t want to take any unnecessary weight to altitude,” explains Wilke, flight test lead for SolarEagle, underscoring the key challenge of keeping an airplane in the sky as long as possible: Make it light so it needs very little energy to stay aloft. Energy, then, becomes the limiting factor. SolarEagle will draw its power from the sun, with solar panels carpeting a wingspan almost twice that of a 747. Such endurance will require solar cells and an energy storage system so light and efficient that they have not yet been fully developed.

In September 2010, the design became the winner of the Vulture II program, a competition run by the Defense Advanced Research Projects Agency (DARPA), the U.S. military’s group that funds concepts bordering on the impossible. DARPA has now committed $89 million to the prototype. Everyone involved hopes to see SolarEagle, now under construction in St. Louis and near Seattle, combine the durability of satellites with the lower cost and flexibility of airplanes, and, of course, meet the central challenge from DARPA: fly for five years without landing.

SolarEagle and similar high-altitude, long-endurance prototypes are stretching our notions of airplanes. Their spindly, giant wings push the limits of aerodynamic efficiency. They fly high and slow without refueling, and shrug off maintenance schedules and ground crews. An autopilot flies a preplanned route while ground-based operators make sure it stays on course.

In the 1990s, NASA sought to develop a fleet of such UAVs for environmental research. The program ended in 2003, when unpredictable winds tore up Helios, a prototype built for the program by a pioneering company in unmanned flight, AeroVironment. The technology has since evolved. Advances in solar cells from the green energy industry, more efficient batteries and fuel cells, more durable engine parts, and new aerodynamic designs may now offer the tools to keep an airplane aloft for years.

“You’ve had a convergence of technology at the same time you’ve had a real need emerge,” says John Langford, chairman and president of Aurora Flight Sciences, which specializes in UAVs. In November his company unveiled a mid-altitude UAV that burns diesel fuel and will stay aloft for five days. “There’s no other place in aviation where you can be talking about this kind of potential,” Langford says.

The dream of indefinite endurance is now closer than ever, says Craig Nickol, a NASA researcher who led a concept study on high-altitude, long-endurance UAVs in 2007. What does he mean by indefinite? “Well, something will always break on you,” he reasons. But he points to SolarEagle. “Five years—that’s, I would say, pretty much indefinite.”

The key challenge, says Nickol, is efficiency. “You basically need state-of-the-art, revolutionary...breakthroughs in each of these areas to enable the goals of some of these programs,” he says.

Engineers are squeezing out every ounce of unneeded material to the point where “now you get into very flexible structures,” says Nickol. “So a lot of the challenge is analysis and design. That’s a new area to deal with, because there are not a lot of good analytical tools that can handle this.”

“In a normal airplane, you can make up for shortcomings in aerodynamics by getting more power,” says Langford, who helped pioneer human-powered flight with the record-setting, human-pedaled aircraft Daedalus, which a pilot flew 71 miles across the Aegean Sea in 1988. “In these airplanes, you don’t have that luxury.”

The efficiency of solar cells, the power source for many high-altitude, long-endurance UAVs, has generally doubled over the last 10 years. Fuel cells, which convert hydrogen to water and can charge onboard batteries for flying at night, have continued to shed pounds. With no moving parts, fuel cells mean reliability.

O’Neil, the SolarEagle program manager at Boeing’s Phantom Works, calls the UAV a “pseudo-satellite,” which would fly at about 65,000 feet, circling combat zones or other targets. “The key technologies have now emerged enough that we can talk about designs that inhabit the upper atmosphere,” he says. “Ten years ago the technologies were not ripe.

“Your candidates are undoubtedly the composite family of materials,” O’Neil continues, “whether you’re talking soft skin over a composite frame or honeycomb, or very lightweight composite plies [sheets or surfaces], where you might have just a couple of plies in key areas just to keep the weight down.” Plastics and carbon fiber are attractive to engineers because of their strength and light weight.

But prolonged exposure to extreme altitude means dealing with ultraviolet radiation and even the occasional gamma particle from space. On the interior, some metals may be needed to shield avionics from these threats.

For early lessons learned on high-altitude, long-endurance flight, O’Neil points to a Boeing program, Condor, that he sees as a jumping-off point. In 1988, the all-composite Condor, with a wingspan greater than that of a B-52, set an altitude record for piston-powered airplanes—67,000 feet—and stayed aloft for two and a half days on its turbo-charged, liquid-cooled, six-cylinder engines. “Condor continues to serve as a strong technical foundation for a lot of what we’re doing today,” O’Neil says. “And that was an unmanned system. So you’re thinking about something 24 years ago—quite an accomplishment.”

NASA’s Nickol points to the late Paul MacCready, founder of AeroVironment, and his human-powered Gossamer Albatross of the late 1970s. “Basically, once they built these super-lightweight vehicles that were very efficient, the next obvious step, instead of having a guy pedal, was to put in solar power and electric motors. So I think the real breakthrough was Solar Challenger. That flew across the English Channel [in July 1981] and actually flew quite a bit farther. At that point they had proof that, Hey, this could work. But then the technology had to catch up.”

It has caught up with manned flight too. Solar Impulse, a piloted airplane, flew from Switzerland to Belgium last May, the first international flight of a manned solar vehicle. Pilot and company CEO André Borschberg reported that he gathered more energy in flight than he needed, and used no more energy than if he had made the trip on “a small scooter.” The goal of Solar Impulse is an around-the-world flight.

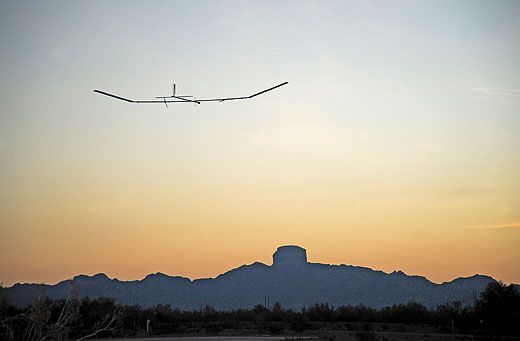

SolarEagle will have some catching up to do when it begins flying. Last summer a wispy airplane called Zephyr flew as high as 70,740 feet above the Arizona desert for two weeks, quadrupling the previous record for flight duration by a UAV. Built by the British military firm QinetiQ (pronounced “kinetic”), Zephyr is the descendant of a smaller solar airplane originally dreamed up to capture video of a record-setting balloon flight. The balloon flight never happened, but the British military got curious about Zephyr’s potential. More recently, Boeing has brought QinetiQ on board as a partner to develop SolarEagle.

Zephyr weighs about 110 pounds and carries a payload as heavy as a telephone book, yet its 74-foot wingspan provides so much lift that it can be launched by hand: Five of the company’s employees hoist it to shoulder height and run along until it lifts away. It lands on two four-inch launch handles on each wing, and comes to an almost immediate stop with no damage. Solar cells as large and thin as a sheet of loose-leaf paper blanket Zephyr’s wings, silently powering twin propellers at a cruise speed of about 14 mph at sea level and almost 70 mph at altitude. The cells also charge lithium-sulfur batteries, which supply more than twice the energy per weight of any other battery type. Zephyr descended a few thousand feet at night and relied on the batteries alone to continue, but future flights are intended to maintain altitude overnight. An earlier model of Zephyr bounced hand-held radio transmissions about 350 miles between Phoenix and San Diego, showing its worth as a communications relay. The UAV’s steady flight also makes for prime surveillance. “It doesn’t have the shake and shudder of a jet engine,” says chief designer and pilot Chris Kelleher. The narrow-field-of-view lenses used at extreme altitudes are often compared to looking through a soda straw, which requires that the camera not shake. “You can look down that drinking straw very stably,” he says of Zephyr.

Kelleher has always loved airplanes that push boundaries, and has won titles for aerobatic flying in England. He also spent 20 years planning launch trajectories and flight dynamics for military satellites. “It was all good fun,” he says now. “But you start to think, Is there another way of doing some of these things? ” High-altitude UAVs, he says, provide constant views for far less cost than satellites. “You do it with a telescope from orbit or a pair of binoculars from [a high-altitude aircraft].”

An operational version of Zephyr is about a year away. While satellite instruments may take years to test because they become untouchable after launch, “we can have a problem in the morning and be flying a solution on a subscale test Zephyr in the afternoon,” Kelleher says. “Our design cycle is very short, and that means advances can be very rapid.”

Boeing and DARPA are counting on that for SolarEagle. While Zephyr set its records above sunny Arizona during the long days of midsummer, DARPA has more ambitious expectations for SolarEagle: The operational version will be designed to fly for months on end at latitudes closer to those of Chicago through the winter solstice, when darkness reigns nearly two-thirds of every day.

“Most aeronautical engineers would tear their hair out over this, and I haven’t got much left,” Kelleher says. SolarEagle’s wings will stretch about 400 feet, with solar panels on almost every exposed surface—even the undersides of the wingtips, which are canted upward, to catch extra rays from the low winter sun.

The blessing and the curse of huge wingspans is that they’re much more at home high above most wind and weather than in the lower atmosphere or on the ground, where they’re vulnerable to winds and ground handling. Because of their delicate, lightweight construction they flex in flight, sometimes changing their aerodynamics in unpredictable ways that suddenly alter the behavior of the airplane.

In June 2003, when AeroVironment’s solar-powered Helios, a 247-foot-span flying wing, took off from the Navy’s Pacific Missile Range Facility on the Hawaiian island of Kauai, engineers knew its vulnerabilities. Like today’s designs, Helios was light and flexible and most at risk in the thick air and winds during its initial climb. It maneuvered between clouds to keep its solar panels illuminated as it rose to about 2,800 feet in half an hour. Weather balloons launched preflight provided data that enabled ground controllers to steer the aircraft away from wind shear zones. Then the view from a wingtip camera went haywire. Unknown to the operators, the wiry airframe was bending in unexpected turbulence like a crossbow with the string pulled too far back. Helios began to wobble, and surged to about two and a half times its maximum design airspeed, about 20 mph, for that altitude. Skin and solar cells began to rip away, and Helios disintegrated into the sea.

“This class of vehicle is orders of magnitude more complex than it appears,” concluded the NASA Mishap Investigation Board. Conventional design techniques “did not provide the proper level of complexity to understand” how Helios would handle turbulence. On top of that, NASA’s decision to curtail funding had unexpected fallout: Engineers hoping to attract commercial funding switched to new fuel cells that were 50 percent heavier, and the airframe could not handle the weight.

But there was optimism too. The Helios team “had identified and solved the toughest technical problems,” which would include weight, flexibility of composites, and electric propulsion in high-altitude, long-endurance UAVs, according to the report, giving the United States a strategic advantage in the field. While the board called for better analysis and modeling, the program had affirmed that high-altitude, long-endurance technologies such as solar cells, electric motors, and structural designs had reached new benchmarks that could be applied to future airplanes.

Now, those airplanes are in the air, with more on the drawing board. This year, Boeing hopes to make the first flight of Phantom Eye, an airplane powered by two Ford truck engines that run on hydrogen. Aurora Flight Sciences late last year rolled out Orion, a diesel burner. And AeroVironment had begun testing of Global Observer last year, a hydrogen-powered airplane able to carry 400 pounds for a week at 65,000 feet. Hydrogen supplies about 2.7 times the energy per pound that gasoline does, making it among the most weight-efficient fuels. Global Observer’s four propellers look remarkably small, thanks to their efficiency and the aircraft’s aerodynamics. An accident did occur last April, and is still being investigated, but a second airplane was nearly complete at the time.

Global Observer doesn’t carry solar cells, because most of the higher-latitude regions where the aircraft will operate remain beyond the useful limits of solar power, says Steven Gitlin of AeroVironment. While the company has not developed any solar airplanes since Helios, Gitlin says Helios and other early solar craft such as Gossamer Condor, another human-powered creation of Paul MacCready, prepared the way for Global Observer’s highly efficient design.

One more endurance strategy is to make aircraft lighter than air: Lockheed Martin in 2009 won a $400 million DARPA contract to build a solar-powered airship that would cruise the stratosphere for up to 10 years. Housing a highly sensitive radar system, the airship would supplant lower-altitude Advanced Early Warning and Control airplanes such as the E-3 Sentry and E-2 Hawkeye. But blimps, like satellites, lack the maneuverability and flexibility of airplanes; they cannot go exactly where controllers want, or adjust to new mission demands on the fly.

Designers of winged UAVs believe they have addressed the problems that brought down Helios. New designs include tails to avoid the kind of pitch problems that did Helios in. Operational versions will be ever more autonomous, navigating themselves from one way point to the next, with only occasional oversight. Zephyr, says Kelleher, is a “delight to fly,” requiring only fingertip control once it climbs into the stratosphere. While its aerodynamics improve with altitude, Zephyr’s wings and propellers are optimized for cruising at altitudes from sea level up to those above 60,000 feet, where the air is 1/10th the density at sea level. The altitude also puts the lanky airplanes above winds and threatening weather—Zephyr easily soars over thunderstorms and hurricanes, Kelleher says—and, of more importance for their solar panels, above the clouds. Zephyr’s batteries, manufactured by Sion Power of Tucson, Arizona, have performed very well through hundreds of recharging cycles in ground tests. SolarEagle will carry solid-oxide fuel cells that store power from solar cells during the day for use at night. Boeing identified the highly efficient fuel cells as the only practical means of storing energy, and took the idea to Versa Power Systems of Littleton, Colorado. The company had won federal grants to develop fuel cells as a way to store wind and solar power for the terrestrial grid. They had already developed some concepts for lightweight fuel cells, “so we went back to the drawing board and finally convinced ourselves that we’d be willing to take it on,” says CEO Bob Stokes.

But to do the job on SolarEagle, the fuel cells must be very light and produce more energy per unit of weight. So engineers at Versa are redesigning the cells and thinning their ceramic and metallic layers. The redesign has so far tripled their power output per pound. Versa expects to double even that, which could make fuels cells eventually work for automobiles.

The SolarEagle team hopes to complete a preliminary airplane design in about a year, pushing technology far enough for breakthroughs, but not breakdowns. Other companies competing for DARPA funding proposed even farther-out designs, such as smaller solar-powered airplanes that would take off individually and, once in the stratosphere, link up into a much larger aircraft. As SolarEagle designers push for better solar panels and fuel cells, they’re building reliability into the airplane at every turn. They’re trying to minimize moving parts by controlling the airplane with variable engine speeds rather than control surfaces. “The whole system has to be designed to expect numerous failures and be resilient to that,” Boeing’s O’Neil says. “This is something that’s been done on the satellite side, so the philosophy is there.”

“Whether or not SolarEagle succeeds or fails,” says NASA’s Nickol, “my prediction is, we’re going to have something like it sooner or later. It’s just so attractive. If SolarEagle’s not it, it’ll be something else. I’d say it’s a guaranteed thing that you’re going to have these multi-year-long vehicles in the stratosphere flying around providing all kinds of services at very low cost.”

When Boeing flies SolarEagle in 2014, it will likely do so with a 200-pound payload at the latitude of Albuquerque. The next step would be an operational version designed to carry 1,000 pounds for five years even farther north. By then QinetiQ may have a fleet of Zephyrs roaming the stratosphere. “This is all really a test of how efficient you can make something,” Langford says. “It’s taking sustainability and applying it to aircraft design. Who knows what you can do if you don’t have to stop for gas?”

Michael Milstein wrote about unmanned aircraft being developed for the U.S. Navy in “*Pilot Not Included,” which ran in the June/July 2011 issue.