Electro-mechanical Deicing

Ice kills. That’s why engineers continue to invent new ways to keep it off airplane wings.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/deicing-388-mar04.jpg)

ON MARCH 19, 2001, COMAIR FLIGHT 5054 took off from Nassau in the Bahamas, en route to Orlando, Florida, with 25 passengers and three crew members. At about 6:22 p.m., while cruising at 17,000 feet, the aircraft entered a bank of freezing rain clouds. Pebble-like ice began to coat the airfoils and control surfaces.

Immediately, the pilots activated the deicing “boots,” inflatable rubber tubes mounted on the wings, to break the ice off. Nevertheless, within a few minutes so much ice had accumulated that airspeed decreased nearly 70 knots (80 mph). Flight 5054, an Embraer EMB-120 twin-engine turbo-prop aircraft, began to roll and lose altitude. Only after it plummeted 7,000 feet before emerging from the clouds and exiting the icing conditions were the pilots able to regain control and make an emergency landing in West Palm Beach.

Within the last 10 years, inflight icing has caused two airliners to crash, with all on board being killed, and interest in anti-icing measures has grown markedly. In the interest of safety, the Federal Aviation Administration and NASA have teamed up to improve aircraft ice protection systems.

Ice is most dangerous when it accumulates on airfoils, disrupting airflow and causing a stall, as in the case of flight 5054. In order to gain approval to fly for extended periods in “known” icing conditions—ice that has been reported or forecast—aircraft must receive FAA certification by demonstrating that they are capable of doing so safely. To win certification, aircraft must employ either deicing systems, which shed ice accumulations, or anti-icing systems, which prevent ice from forming. A new system, Electro-Mechanical Expulsion Deicing, does both: It combines anti-icing and deicing measures. Developed by Cox & Company, a manufacturer of electro-thermal systems for marine, aviation, and rail applications, EMEDS is the first ice protection technology to receive FAA certification in 50 years. In 2001, it was certified for use on Raytheon’s Premier 1 business jet.

The technology works in conjunction with previously developed ice detection systems and is triggered automatically once sensors detect ice. First, an electro-thermal strip heats the wing’s leading edge to just above freezing, melting the ice. Other electro-thermal systems heat the leading edge enough to evaporate moisture on contact, preventing it from escaping and refreezing elsewhere as “runback” ice. Such thermal evaporative systems, like those using engine bleed air, require constant high power. “We heat the leading edge but don’t evaporate,” says Kamel Al-Khalil of Cox & Co. EMEDS solves the problem of runback ice by “keeping the water in a liquid state—a very thin film that doesn’t affect airflow,” says Al-Khalil. “The water flows downstream and eventually freezes where the aircraft is less sensitive to airflow disruptions. That’s where [the deicers] hit it.”

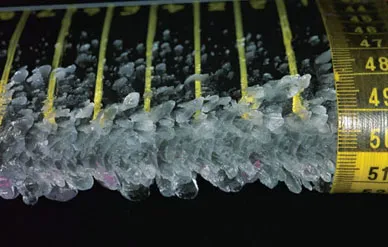

The deicing component of the system includes two sets of elliptical-shaped coils, or rolled circuit boards—one set for the airfoil’s upper portion and one for the lower. The coils are installed behind the heated strip, between the aircraft skin and a rigid housing. An electrical current is sent through one set of coils at a time, and as the current loops through the coil, it flows in one direction and then the opposite, inducing a magnetic field. The upper and lower portions of the coil then repel, changing the coil from an elliptical shape to a more circular one. The shape change, in turn, causes the coil to flex the aircraft skin and break the ice’s grip. Jolted with electrical energy pulses that last .0005 second, the coils deliver impact accelerations of over 10,000 Gs to the airfoil skin once a minute, shedding ice as thin as .06 inch. Despite the high G-load, the impact amplitude—the amount of movement of the aircraft skin—is only about .025 inch. The skin accelerates so rapidly, though, that ice de-bonds as if hit with a hammer.

Despite the impact loads and frequency, metal fatigue isn’t a problem, according to Al-Khalil. “We’ve run millions of cycles” on test airfoils, he says, a duty cycle many times what an airfoil typically experiences in its lifetime, without damage. The system’s service life is better than that for rubber boots, which require regular replacement when the rubber degrades. And the EMEDS system doesn’t disrupt the airfoil shape, as the boots do.

Mechanical deicing may also replace systems using anti-icing/deicing chemicals, which seep out of fine holes in the leading edges of airfoils on aircraft like the Cirrus. Fluid use on the Cirrus is certified only as “No Hazard” to normal flight operations. Chemical systems can be used only in unforeseen and emergency icing conditions.

At 28 volts and less than 10 amps aboard the Premier 1, EMEDS’s power requirements are attractively low compared with the engine bleed air or electrical power demand of thermal evaporative systems.

Raytheon uses EMEDS in the Premier’s tail section and will include it in its other jets. To anti-ice wings and ensure that no fragments reach the engines, the company will continue to use engine bleed air.

EMEDS won’t see wide use in transport aircraft until it is included in aircraft design—literally built into the wing. But it may be accepted faster in smaller general aviation aircraft, where bleed air isn’t available and weight and electrical power limitations are stringent. Many pilots prefer evaporative anti-icing systems. Says Al-Khalil, “Pilots want to use all anti-ice systems. They don’t like deicing, but they’ll live with it.”