They Said It Wasn’t Possible to Escape the Space Shuttle. These Guys Showed It Was.

But the circumstances had to be just right.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/a5/2d/a52d4957-3986-436d-aeb6-3773820878c4/06c_sep2020_shuttlelaunch_9461023176_45f9eb82e3_live.jpg)

The decision would be made at about 60,000 feet. Provided nothing had gone fatally wrong and the space shuttle could still be maneuvered into a stable glide, the astronauts aboard, who only minutes before had been on their way to orbit, would prepare to parachute into the ocean.

As the orbiter descended, the commander would set its controls to autopilot and ask the astronaut sitting closest to the outer hatch, on the middeck below, to depressurize the cabin and jettison the hatch. After making his or her way to the hatch, that astronaut would then yank a handle to deploy a nine-foot telescoping pole out into the rushing air, and hook one of seven lanyards attached to the pole to a metal ring on their parachute harness. Wearing compact, 64-pound parachute packs, the rest of the crew would leave their seats, hustle to the hatch, and hook in too.

Then, one by one, the astronauts would kneel in the hatch and jump into the equivalent of a 230-mph wind. For a split second, they would feel a tug on the lanyard tethering them to the pole, their last contact with the vehicle before they slid off into the rushing air. If they happened to catch a backward glance, they’d see the empty shuttle receding above them, perfectly under control and doomed.

Before January 1986, such a scenario had barely been contemplated. The space shuttle was considered reliable enough that having a bailout option was not considered a priority. The only way for the crew to survive an emergency early in their ascent (and even then, only in some circumstances) was to turn the spaceplane around and fly back to Florida—the so-called “return-to-launch-site” abort.

That all changed on the morning of January 28, 1986, when, 73 seconds after launch, Challenger broke apart, killing all seven astronauts on board. The commission called to investigate the accident made broad recommendations as to how the shuttle program could be made safer, one of which was that NASA should develop a way for the crew to bail out, if necessary, during the launch phase.

There were a very small number of fringe scenarios in which a survivable failure during the shuttle’s ascent or reentry could occur when it was out of reach of an abort site, with nowhere to land. Because the orbiter was built to be light, not strong, a water landing would have been fatal for both it and the crew. After the Challenger loss, the lack of any bailout option, even one that was unlikely ever to be used, now seemed unacceptable.

The “return-to-flight” shuttle mission optimistically was set for July 1987, which gave NASA just a year to design the new escape system, test it, and integrate it into the existing orbiter. But before that could happen, someone had to figure out whether the idea of jumping out of the shuttle at high speed was even viable.

That task fell to Ricardo “Koki” Machín, a young aeronautical engineer who had just been hired at NASA out of college. He put a scale model of the shuttle, about five feet long, into a wind tunnel, and out of its tiny side hatch he pushed a tiny dummy astronaut.

“I just basically plunged the guy out the side,” Machín remembers. “He went tumbling down. Sometimes he hit the back of the vehicle. Sometimes he cleared it. It was horrible looking.”

Clearly the astronauts would need to get farther away from the orbiter before they started their fall. Ejection seats would be impractical in the two-level crew cabin (although the first shuttle test flights, with only two astronauts sitting upstairs, had them). So NASA’s first thought was to emulate a system that had been used in some fighter jet ejection systems, a “tractor” rocket that would pull the pilot out of the aircraft by a tether.

Early tests of the tractor system, which would require the astronauts to lie on their backs in the shuttle’s open hatchway before firing the rockets, tore the legs off the life-size dummies. Even though the kinks were eventually worked out, NASA was nervous about carrying rockets inside the shuttle’s crew cabin. So they went looking for a safer option.

Machín’s boss, Winston Goodrich, came up with the pole idea. It was impressively simple: The astronauts could slide down a kind of fire pole that, after being extended from the shuttle hatch at a certain angle to a specific length, would put them on a trajectory that stayed well clear of the left wing. All they’d have to do was hook their parachute harnesses to a lanyard—consisting of a Kevlar strap with rollers that surrounded the pole—and jump.

Machín tried it on his mini-shuttle. “The pole would work sometimes, but it didn’t always work. Sometimes [the mini-astronauts] would hang up and they just wouldn’t slide down,” he says. Goodrich suggested a curved pole, to get the fall started and launch the jumpers off the end. It worked.

Meanwhile, the shuttle program had to develop a parachute system unlike any that had existed before, one that could be worn over a spacesuit by astronauts who may have little or no skydiving experience. The system had to be foolproof at altitudes up to 25,000 feet and speeds up to 225 knots (259 mph). It had to open the parachute automatically once the astronauts were clear of the orbiter, even if they were unconscious. And it had to include survival gear to keep them alive after landing in what was likely to be the middle of the Atlantic Ocean. The whole thing also had to fit on the astronauts’ backs as they maneuvered through the cramped crew cabin on their way out the door.

NASA took the problem to the Naval Air Weapons Center at China Lake, California, just north of Los Angeles. The Navy’s elite aircraft escape parachute testing team was based there, and the facility’s engineers had experience building complex systems, including for ejection seats. “I remember distinctly saying, ‘If we can’t do it, nobody can,’ ” says Rusty Bates, China Lake’s program manager for the project.

In addition to the main parachute, the system would need a drogue chute to stabilize the astronauts in freefall and a pilot chute to deploy the drogue. In order to be fully automatic, the backpack containing the parachutes had to have a series of “cutters” that would sever a complex network of straps in a carefully prescribed order. “We crammed all that kind of logic and stuff that an ejection seat would do into a backpack parachute,” says Mike Herr, the project’s lead engineer. “Nobody had ever done that level of integration before.”

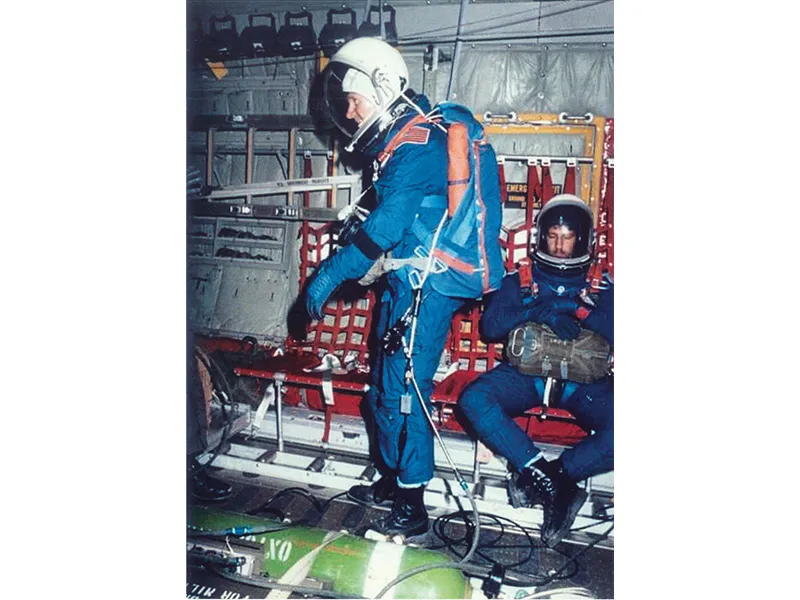

Once Herr and his colleagues had a prototype system up and running, the Navy’s crack testing team began the process of finding out how well it would work. Six parachutists tested the system, one of whom was Steve Sotaski. He was 27 years old at the time and already a master skydiver. “[It didn’t seem] like work to us,” he says. “Hurling yourself out of an airplane is a blast.”

Back at NASA’s astronaut office, the whole project was viewed with a healthy dose of skepticism. In his 2006 memoir, Riding Rockets, Mike Mullane recalled, “Many of us placed the slide-pole bailout procedures in the same category as the pre-Challenger contingency-abort procedures—busywork while dying.”

Still, it was worth testing.

Pinky Nelson, one of the five astronauts picked to fly on the first mission following Challenger, rode along for many of the test jumps. “[The test parachutists] were having a ball,” says Nelson, who to this day has never jumped out of a perfectly good airplane. “I wouldn’t have done it on a bet.”

Parachutists had jumped from fast-moving cargo airplanes before, but usually out the back door, where the aircraft’s slipstream provided less turbulent air to jump into. The shuttle crew would need to go out a hatch in the side of the orbiter, where they’d hit the full force of the wind right away. In early test jumps from a twin-prop DHC-5 Buffalo, one of Sotaski’s colleagues didn’t quite clear the aircraft once he hit the windblast. “We’re supposed to go out and do a military tuck-type rollout and stay in that position until you clear the aircraft,” says Sotaski. “He started going into his free-fall body position a little too soon, and part of his boot slid down the side of the aircraft and left a little boot mark on it. It was kind of funny.”

Eventually Sotaski and his team moved their operation to Edwards Air Force Base in California, where they started testing the pole-and-lanyard system with the pole extending out the rear side door of a C-141 Starlifter. “We had two dummies,” says Sotaski. “We called them Milt and Shirley. They were actually the first two that ever did the pole. Then I was the first human being to ever do the jump.”

During one early test with the dummies, Milt or Shirley’s parachute failed to open. Bates, the program manager, went looking for it with veteran astronaut Steve Nagel, whom NASA had tapped to help oversee the project. When they eventually located the unfortunate dummy, Bates remembers Nagel looking up at him and saying, “Rusty, why don’t I feel good about this?”

When it was Sotaski’s turn, he wore a telemetry box and antennas to beam data back to engineers on the ground, including the readout from a strain gauge on the lanyard connecting him to the pole as he fell. Those numbers would eventually go into computer simulations of the shuttle in flight. For quicker results, Machín, who was now leading NASA’s aerodynamics team for the escape system, would project video of each jump onto a whiteboard and plot the jumpers’ trajectories. He’d then superimpose those onto a computer mockup of the shuttle. If the falling parachutists in the video cleared the virtual shuttle’s wing, it was a sign that things were coming along.

Developing the parachute system was one thing; integrating it into the shuttle and making it usable for the astronauts was another. Because the decision to bail out could happen very quickly, the astronauts would need to be fully suited up for the jump before the shuttle even left the launchpad. To allow them to sit with their parachutes on, the crew seats were modified so that the pack doubled as the seatback cushion.

For Herr and his fellow engineers, fitting all the necessities into the backpack was a little like packing a tiny car for a long trip. In addition to the parachutes themselves, the pack had to hold two oxygen tanks, a small inflatable raft and life preserver that would automatically deploy when the jumpers hit the ocean, a water scoop, sea dye markers, a signal mirror, emergency food rations, two liters of water, and a strobing rescue light. And the pack had to fit on any of the astronauts, who could range from 5’2” to 6’3” in height.

“The biggest issue was the small females,” says Herr of designing for the different body types. The backpacks had to be one-size-fits-all (in case of last-minute crew changes), which meant the smallest astronauts were dwarfed by their packs. Herr’s team had to develop a custom-fit harness so the pack wouldn’t slip off their shoulders.

Only two of the Navy jumpers tested the full “altitude protection suit,” including helmet and survival gear. They were the largest guy on the team, Sotaski, and the smallest, Bob Hudson, to bookend the range of sizes among NASA crews.

Skydiving in a spacesuit wasn’t painless. Sotaski and Hudson sustained lacerations when landing on solid ground, as their heads bounced around inside the metal neck ring that connected the suit to the helmet. They started wearing padded skullcaps to limit the damage, but that didn’t make it any more fun. “I was more afraid of my landing than I was the jump,” says Sotaski.

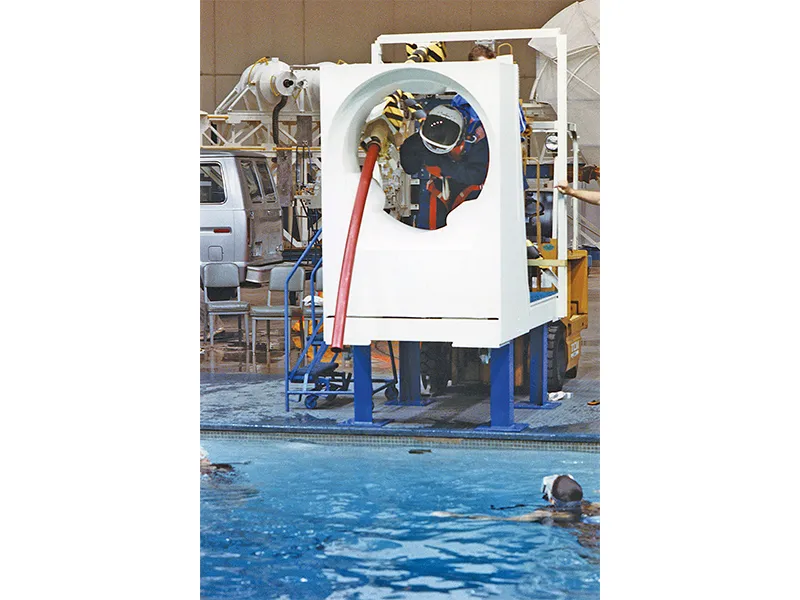

The shuttle astronauts all drilled with the crew escape system and survival gear until they got proficient. NASA mounted a mockup of the shuttle hatch and pole assembly above their spacewalk training pool in Houston so they could practice. Pinky Nelson found himself thinking mostly about the very last part of the bailout. Abandoning the space shuttle at altitude was one thing, but he mostly worried about what would happen once he was in the ocean. “I always thought it was kind of scary,” he says. “I’m really comfortable in the water, but being in the water in a heavy suit with a helmet on that that can fill up with water was never my idea of fun.” As soon as he’d drop into the pool, Nelson would be sure to take his helmet off.

He can’t help laughing, remembering his plunge from the fake hatch into the water. In an accident scenario, “the odds of [the orbiter] being intact and flying at 10,000 feet were really pretty small,” he says. Still, there was no sense leaving the possibility open that he and his crewmates could end up wishing they’d had parachutes or known how to use their survival gear. “The odds may be really small,” he remembers thinking, “but if we get [to the point of needing to bail out], I’m going to do this right.”

The crew escape system was never used on an actual mission, although there was one mishap where one of the pilot parachutes accidentally deployed in the crew cabin while the shuttle was in space (one of the astronauts who had skydiving experience swapped his backpack for that one, planning to pull his chute manually if he ended up needing it, which he didn’t).

Once the shuttle escape system tests were complete, the China Lake engineers went back to working on ejection seats and other Navy projects. Three of the six test jumpers, including Sotaski, went on to provide parachuting support for the Navy SEALs. Machín would eventually become chief engineer for the parachute system on NASA’s Orion crew capsule designed for travel beyond Earth orbit in the 2020s. In September 1988, more than two years after the Challenger accident, Pinky Nelson strapped in aboard space shuttle Discovery for the long-awaited return to flight.

As the only crewmember seated on the middeck, he was assigned the job of jump master—if necessary, he would be the one to install the pole-and-lanyard magazine and blow the hatch. His only instrument was an altimeter bolted to the locker in front of him, to tell him when to start “throwing guys out of the hatch.”

Says Nelson: “I always told them that I would probably lead by example.”