These Frankenplanes Are Built From Parts of Other Planes

Some monster aircraft were not born. They were bolted together from whatever lay at hand.

:focal(1370x773:1371x774)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/0e/de/0ede8e60-688b-448a-8777-70c156157b9f/09i_fm2021_dc_25b_live.jpg)

The big silver airplane parked in an open field was the only worthy target for miles. The Japanese bombers quickly sieved the exposed Douglas DC-3 with hundreds of machine gun bullets. Hugh Woods, a pilot with China National Aviation Corporation (CNAC), was watching from a nearby hillside. His heart sank as a 100-kilogram bomb detonated under the right wing of his aircraft, throwing dirt, grass, and splintered aluminum across Suifu airfield.

His crew and passengers were alive and unharmed, but his precious airplane was gone. With the wing mangled, there would be no chance of escape. More attackers would soon return to finish the job. The best Woods and his men could do was to hide the wounded airliner among the trees, radio back to base, and hope for a miracle.

In the spring of 1941, Douglas transport aircraft were nearly priceless in China. When CNAC’s chief of maintenance Zygmund “Sol” Soldinski received the news in Hong Kong, he decided it was well past time to start drinking. As Sol downed a few glasses of White Horse whiskey, he deliberated the problem with managing director P.Y. Wong.

There was no spare DC-3 wing in China. Douglas Aircraft Company would take months to make another one. And then they couldn’t ship it, at least not on an American vessel. There were wartime neutrality laws. Even if they had a wing, and it was in Hong Kong, how would they get it 860 miles into the middle of nowhere? By ship, then via truck? There was seemingly no practical way to get the job done.

Shuffling back through CNAC’s hangar, Soldinski approached a group of mechanics, overhauling a Douglas DC-2. When he suddenly asked the men if a DC-2 wing might fit on a DC-3, they gawked at him, speechless. Surly old Sol had finally gone mad.

But as they measured, calculated, and experimented, it soon became clear that Sol, even slightly tipsy, had pretty good instincts. Thrifty Donald Douglas and his engineers had in fact used the DC-2 wing and center section butt plate jigs for their newer DC-3. It wasn’t a perfect fit, but it would work, assuming that the repaired aircraft could fly safely with a replacement wing that was almost five feet shorter than the original.

Reinvigorated, they hatched a plan to sling the spare wing under the belly of a CNAC DC-2 with the tip facing aft. Crewmen built a temporary fairing over the exposed wing butt to maximize aerodynamic flow over the unusual load.

When the replacement wing finally arrived at Suifu, it took crews several days to patch up the DC-3, remove its maimed right wing, and put the new one in place with the help of shims, freshly drilled holes, and more than a little prayer. All the while, the men watched the skies, hoping the Japanese wouldn’t appear again to spoil their work.

Though seemingly hopeless at the start, Sol’s hare-brained plan succeeded. CNAC pilot Hal Sweet took off in the battered bird and reported it flew surprisingly well, though the airplane constantly pulled off to one side like a car that was severely out of alignment. Upon safe arrival in Hong Kong, CNAC mechanics took several photos of what they jokingly called “The DC-2½” before they began the long job of repairing the aircraft.

This strange adventure in China is by no means the only instance of an aircraft built from two or more airframes. The fighting of World War II resulted in a number of odd mongrels constituted from parts.

TWO HALVES MAKE A WHOLE

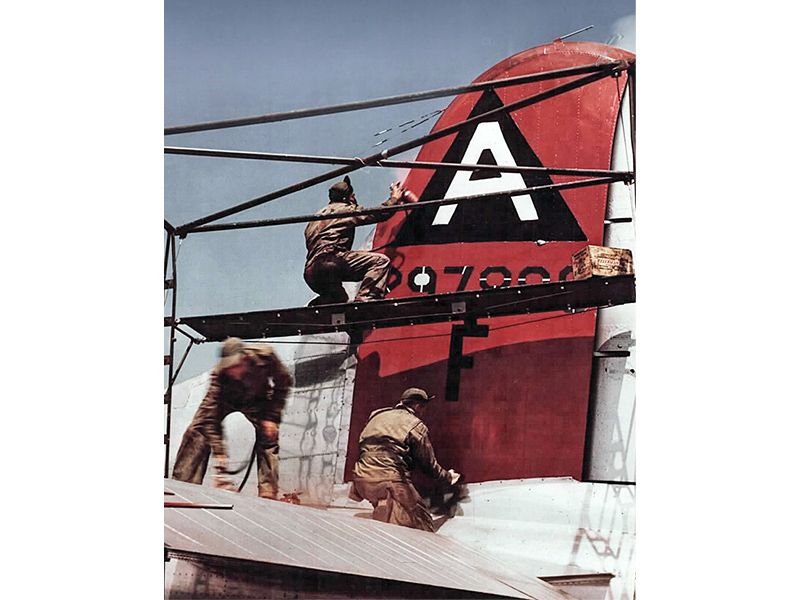

During the American bombing campaign in Europe, the Eighth Air Force needed every fighting aircraft it could get, which often meant making heavy repairs to severely damaged bombers. In October 1944, a B-17G nicknamed Little Miss Mischief absorbed a devastating blast from a German 88mm over Cologne. While the bomber returned safely to the 91st Bomb Group’s home airfield at Bassingbourn, it left ground crews with a massive repair job. The nose and wings of Little Miss Mischief were almost untouched, but the aft fuselage, ball turret, and waist area were a mess. In order to return the bomber to action, ground crews went shopping for a donor aircraft.

They found what they needed some 25 miles to the north at a salvage depot. Wallaroo Mark II of the 303rd Bomb Group had taken a flak blast near its nose on a mission over Berlin in April 1944, then suffered a main landing gear collapse the following August. The B-17’s tail was mostly unharmed, and would be a perfect donor for Little Miss Mischief.

Over 40 days, the men of the 441st Sub Depot at Bassingbourn joined the Boeing-built tail of Wallaroo to the Lockheed subsidiary-built front of Little Miss Mischief at the break aft of its wing where the factory had joined the two halves. Using parts from 13 other aircraft, they also replaced cowlings, wing panels, and the bomber’s vertical tail. The results were striking: The front half—Little Miss Mischief—was bare metal, while the rear—Wallaroo—was painted faded olive drab over gray.

DESPERATE COMBAT REQUIREMENTS

Little Miss Mischief wasn’t the only bomber made into a Frankenplane; American repair crews regularly cannibalized aircraft due to spare parts shortages. In the European theater, a U.S. Army Air Forces heavy bomber lasted an average of 215 days—and was in repair, maintenance, or modification for about 49 of those.

When a B-17G assigned to the 457th Bomb Group had its tail crushed in a July 1944 ground collision with another B-17, the olive drab aircraft received a salvaged bare metal backside. The crew gave the mismatched aircraft the name Arf n’ Arf after a popular drink that was half mild ale and half bitters.

Arf n’ Arf flew missions until November 8, 1944, when poor weather canceled a bombing sortie while the aircraft were already flying toward Germany. As the formation turned west, yet another B-17 collided with Arf n’ Arf, its propellers slicing into the belly of the bomber. The patchwork airplane fell into the North Sea, bisected at almost the exact point where it had been joined together months before. There were no survivors.

THE PHOENIX RISES

The most famous Frankenplane was intentionally built to look like a homemade mess. In the 1964 novel The Flight of the Phoenix, 12 men stranded in the Libyan desert construct a new airplane from the wreckage of their crashed Fairchild C-82 Packet cargo aircraft. For the 1965 movie, the producers called upon California-based Tallmantz Aviation to supply the flying prop aircraft.

The fuselage and tail of the homebuilt machine were made of tube steel and plywood, shaped to look like the salvaged boom of the fictional Arabco Oil Company’s C-82. The wings were taken from a defunct Beechcraft C-45, and the tail wheel came from a North American L-17 Navion. Builders salvaged an engine, cowling, and propeller from a North American T-6 trainer. The one-of-a-kind aircraft was inspected, deemed airworthy, and assigned the name Tallmantz Phoenix P-1 in the FAA paperwork.

When an injury sidelined primary pilot Frank Tallman, his Tallmantz Aviation partner took over. Paul Mantz was an accomplished movie pilot, air racer, and aviation consultant with over 25,000 hours in the air.

While filming in Arizona’s scorching Buttercup Valley on July 8, 1965, Mantz and stuntman Bobby Rose swooped the Phoenix low—just a few feet off the desert floor. The footage captured by multiple camera angles would be edited to look like the final, victorious takeoff of the once-stranded survivors.

During a second pass the airplane settled, its skids thumping onto the sand. With the jolt, the tail of the Phoenix sagged and then broke free, the wings and cockpit of the broken aircraft lurching forward and then tumbling into the rocks and sand. Rose was seriously injured, but survived. Mantz was killed by the rolling wreckage.

NOSE JOB

In August 1969, terrorists were responsible for one of the world’s largest Frankenplanes. When the members of the Palestinian Popular Front for the Liberation of Palestine learned that Yitzhak Rabin, then Israeli ambassador to the United States, would be aboard TWA Flight 840, they made plans to hijack the Boeing 707-331B.

Rabin wasn’t on the Rome to Tel Aviv flight; but an American diplomat was, along with 94 other passengers and 12 crew members. The terrorists ordered the pilots to land at Damascus International Airport; after evacuating the passengers from the airplane, they detonated a bomb in the empty airliner’s nose, creating $4 million of damage.

After Syrian authorities took control of the scene, TWA adjusters and executives went looking for a way to save the aircraft.

Upon thorough examination, Boeing techs noted that a majority of the big jet was unharmed. The exception was “section 41,” the cockpit and nose, which was shredded almost beyond recognition.

For years, the rumor persisted that TWA finagled a donor nose from the remains of a heavily fire-damaged BOAC airliner. In reality, TWA brokered a deal with the Boeing Company to supply a factory-fresh nose section directly from the Renton, Washington assembly line. The massive “spare part,” which amounted to nearly everything ahead of the 707’s forward-most passenger window, was airlifted halfway around the world with the help of Aero Spacelines’ Mini Guppy. In Syria, a 58-man crew worked for weeks to get the wounded 707 back into the air.

In the years following the hijacking, passengers and even many TWA flight crews had no idea they were flying on a heavily-repaired Frankenplane. Airline officials quietly changed the 707’s registration to erase the most obvious hints of the jet’s life-saving surgery in the Middle East. After thousands more passenger flights, TWA finally retired the airplane in March 1980. But even when the airliner, as a whole, ceased to exist, portions of it kept on flying. Sold to a military spares program, components of the 707 flew as parts of U.S. Air Force KC-135 tankers for decades more.

SUPERSIZE ME

The Guppy that delivered the nose section to TWA Flight 840 was also a Frankenplane. In the 1960s, Aero Spacelines, Inc. acquired and heavily modified a series of retired Boeing 377 airliners and C-97 cargo aircraft for the sole purpose of transporting huge loads by air. As the Spacelines name implies, one of the company’s biggest customers was NASA.

A total of eight strange-looking aircraft—one Pregnant Guppy, five Super Guppies, and two Mini Guppies—transported huge sections of Gemini and Apollo rockets, space capsules and probes, as well as other massive but delicate items in need of quick and careful delivery.

Each type of Guppy was different, but all of them flew with an enlarged upper fuselage and sported a removable tail or hinged nose to accommodate the most humongous objects. The first Guppy was built from a retired Pan Am 377 lengthened with the fuselage section of a scrapped BOAC Stratocruiser.

Some of the subsequent aircraft used new engines, modified tails and wings, and nose gear assemblies taken (and turned backward) from a Boeing 707. It was the final Guppy type, a Mini Guppy named Spirit of Santa Barbara, that delivered the factory-new nose to the bomb-blasted TWA airliner stranded in Syria.

A NEW MONSTER AWAITS...

Nowhere will you find more cannibalization of airplane parts than in the air racing community. One of the most notable Frankenplane racers has yet to be completed, but the plans were as audacious as the career of the racer who dreamed it up.

Former SR-71 test pilot and air race champion Darryl Greenamyer put together his 1977 world-speed-record-holder F-104 Red Baron from pieces of at least a half dozen Starfighters. Greenamyer’s final project was Shockwave, an Unlimited Class racer he hoped would shatter the current piston-powered aircraft speed record.

Shockwave’s airframe has a scratch-built fuselage and wing center section mated to a World War II-era Hawker Sea Fury’s outer wings and the tail of a jet-age North American F-86 fighter. The one-of-a-kind machine might one day scream overhead at more than 600 miles per hour, powered by a monstrous 28-cylinder Pratt & Whitney R-4360 Wasp Major engine generating a potential 5,000 horsepower.

Sadly, the ground-breaking but tremendously expensive project wasn’t completed at the time of Greenamyer’s passing in October 2018. Shockwave has since been sold to an undisclosed buyer; for now, it languishes in a hangar. We await the day it will finally roar into the skies.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/b9/d6/b9d6478c-6762-481a-9fd1-a9b6cc6ad4d1/09r_fm2021_b17bigbarndamage29713unknown-if-highres_live.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/c0/14/c01468c1-c010-464c-8059-63b7fe249543/09u_fm2021_twaboeing707-331bsyrianosereplacementboeh36784_live.jpg)