These College Students Want to Make Sure No Pilot Ever Runs Out of Gas

It’s more common than you think, and as dangerous as you might expect.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/8c/f8/8cf8835c-e5cc-4cff-a9fe-d0eac7eb6a77/02d_on2021_andrewking16_live.jpg)

Undergraduates Taylor Peterson and Cassandra Bossong were in class in February 2020 when a notification popped up on Peterson’s laptop. It was from the Massachusetts Institute of Technology, and it bore one word: “Congratulations.” Peterson slammed her hand on the table. “We won!” she blurted. Peterson and Bossong, along with fellow physics majors Nicholas Bartel, Bennett Bartel, and Celestine Ananda from Carthage College in Kenosha, Wisconsin, had just clinched a $10,000 award for promising collegiate inventors—the 2020 Lemelson-MIT Student Prize. Their achievement: a new way to alert airplane pilots that they’re running out of gas. The technology, called modal propellant gauging (MPG), uses sound frequencies to determine fuel levels. It adapts for use on airplanes an experimental method for measuring spacecraft fuel. The MPG team was one of six student prizewinners, after contending with some 200 competitors from higher-profile universities.

“We were all in a state of shock and disbelief,” recalls Ananda, their former team leader, who graduated in 2020 and is now a doctoral student in aerospace engineering at the University of Colorado. “But that turned into a kind of humility and pride that, even though we come from a very small school, we still have the chops to compete against students from Stanford, MIT, and Caltech.”

The Carthage team’s work expands upon research pioneered by faculty advisor Kevin Crosby, a physics and astronomy professor who worked for years with NASA research engineer Rudy Werlink. Werlink, the project manager at NASA’s Kennedy Space Center, came up with the idea, and Crosby coined the name for the technology. A decade of NASA-funded experiments by Carthage students supplemented their research, as did input from pilots of small airplanes.

“Because we have an entrepreneurship component to our curriculum, the students had already begun thinking about how to translate what they were doing to other fields,” says Crosby.

Not Running on Empty

Unreliable fuel gauges have long vexed both aviation and space industries. The National Transportation Safety Board (NTSB) ranked fuel-related issues as the fifth-leading cause of aviation accidents in 2017, the most recent year for which data are available. That year, running out of gas accounted for 79 of 1,233 accidents, a total that averages to 1.5 a week. An NTSB Safety Alert that year reported fuel management caused, on average, more than 50 aviation accidents a year from 2011 to 2015. Most of those involved smaller craft.

In space, conventional methods of measuring propellant volume haven’t accounted for the way liquid behaves. For example, the space shuttle’s capacitance-probe system—which correlated changing electrical charges to differing fuel levels—failed in microgravity when the fuel evenly coated the tank and probe, providing a false “full” reading. Its pilots learned to estimate fuel levels through indirect methods, such as measuring tank pressure or recording duration of engine burns. Today, international space treaties demand a six-month margin of propellant for satellites on 10-year missions so that they can be moved to graveyard orbits at the end of their service.

That means satellites might carry more fuel than necessary, a big deal for the weight-conscious industry. “Across the industry, that six months amounts to billions of dollars annually in lost revenue and payload mass that you can’t take, just because you just don’t know how much fuel is in that tank,” says Crosby.

Although engineers have come up with promising new approaches, NASA budget constraints and differing agency priorities impeded major investments in them. Lately, more affordable testing methods coupled with a planned crewed return to the moon under NASA’s Artemis program have won more attention for ways to measure fuel accurately.

“NASA has been very interested in using this for space and satellites, but this hasn’t been taken to the aircraft market,” says Ananda. “That was something that hadn’t been considered before, and we thought it could make a really big impact.”

Commercial jets use capacitance probes akin to those used on the space shuttle, which are more reliable in gravity but far too heavy and complex for small airplanes. Most light airplanes use a buoyant float with a lever arm whose changing position electronically reports fuel levels as the tank empties.

“In smaller aircraft, fuel gauging is basically the same technology that’s in your car,” says Crosby. “So if you’re accelerating, climbing, descending, there’s turbulence, or you’re pitching or rolling, the fuel gauges jump around a bit.”

“The primary reason for fuel-gauge inaccuracy is that the float tends to stick,” says Phil Holcomb, a flight instructor at Spring City Aviation in Waukesha, Wisconsin, who mostly uses Cessna, Piper, and Cirrus airplanes. “The one big thing that I emphasize with students is to visually check tanks with a fuel stick for accurate fuel quantity during preflight inspection. Knowing how much fuel is in the tank and how much your hourly burn rate is, you can make a safe assumption on how long you can be in the air.”

Even with safety buffers, like reserve fuel and preflight planning, faulty gauging can trap even the most seasoned fliers. Ed De Reyes, a retired U.S. Air Force experimental test pilot who is now CEO of Sabrewing Aircraft in Oxnard, California, once had to make an emergency landing in his Cirrus SR-22 after his fuel gauge indicated a rapid drop to a quarter of a tank, only to find afterward it was more than 60 percent full. “I still have no idea what caused that, but smaller airplanes are notorious for that,” he says. “I’ve had other times when fuel gauges told me I had more fuel than I actually did. I’ve seen airplanes where you fill it up entirely with gas, you turn on the power, and the gauge just shows a half or even a quarter tank.”

The problem is even more pronounced for aerobatic fliers. “The airplane’s really only going to give you an accurate read on the fuel gauges when you’re at straight and level flight,” says Matt Stephenson, a Eureka, California aerobatic pilot who flies a Super Decathlon. “When you’re doing aerobatics, you’re pretty far from that.”

Adapting MPG technology from space to aviation presented two challenges: re-designing the device and calculations to account for gravity and assessing the market for its use in aviation.

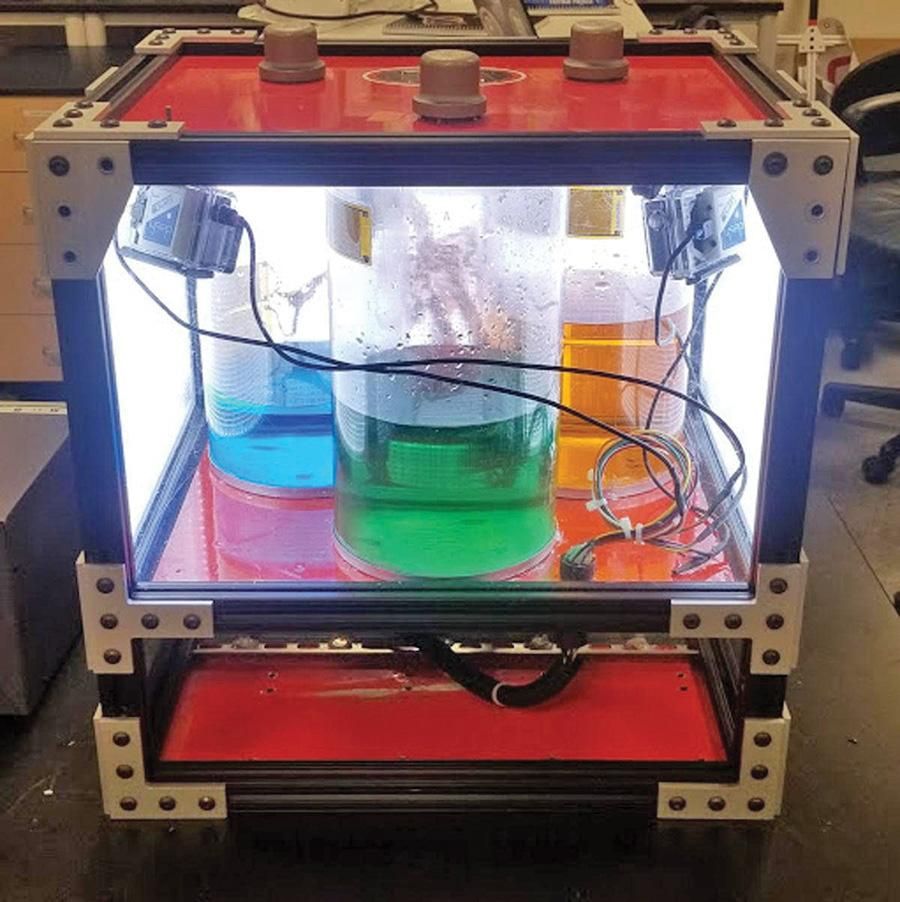

MPG—which can be added to existing fuel gauges without structural modifications—uses sensors that record the tank’s changing acoustic vibration as the fuel volume depletes. One sensor vibrates the tank while two others record the response of the tank to the vibrations. Dividing the response from these two sensors provides a set of frequencies representing a unique “fingerprint” for the tank that contains information about its mass. When fuel sticks to the walls, it adds mass to the tank, changing some of those frequencies. MPG can detect and associate these small shifts with the volume of liquid in the tank.

Still, the amount of fuel hitting the tank wall plays a role. In microgravity, liquid spreads uniformly along the inner surface of the tank. But in aircraft, fuel sloshes unevenly against the tank, producing a different set of frequencies than the same volume would in zero gravity. Students had to adapt their calculations to accommodate this difference.

The market study, which cites a potential $150 million in annual earnings, proved more complicated for the physics majors than adapting frequency measurements. They had to investigate ways to scale manufacturing without forfeiting quality.

For instance, space-grade material has to be able to withstand radiation and vibration, and not emit gases. “All of these qualifications make for very expensive components, but aren’t necessary for aircraft or for ships,” says Ananda. “So our team looked into a lot of ways to make this much cheaper and mass-producible in the future.”

Promoting Undergraduate Research

Crosby founded the Carthage College space sciences program in 2006 to foster undergraduate space research. Two years later, its participants began working with NASA through its now-defunct Systems Engineering Educational Discovery (SEED) program, pairing student teams with NASA researchers for microgravity experiments. Their work with Werlink started in 2011, after he put out a call through SEED for student experiments to help test his ideas for MPG technology. When SEED ended in 2013, Crosby assumed the role of principal investigator and obtained other NASA grants. The agency’s recently awarded Flight Opportunities grants will support MPG zero-gravity testing for NASA’s Gateway lunar outpost, a component of the Artemis mission.

“We’re a small college in the Midwest with no engineering program and few nearby aerospace employers, and we have students who are going off to work at NASA, Boeing, and Blue Origin,” says Crosby.

A major perk has been testing their work aboard Zero Gravity Corporation’s parabolic flights that simulate 20 to 30 seconds of weightlessness. The students have also run experiments on uncrewed parabolic flights to space aboard Blue Origin’s New Shepard rocket.

“Experiencing zero gravity is just the coolest thing in the world,” says Ananda. “The problem is after you do this for an hour and the adrenaline starts wearing off, I’d almost always inevitably puke on the very last parabola. It’s not great, but it’s definitely worth it.”

Crosby has raised more than $13.4 million over 11 years for the space sciences program, which now comprises six projects, three of which involve MPG tech. The MPG experimentation continues. The approach is among the leading contenders for NASA’s next generation of fuel gauge solutions and was recently approved for a 30-day test aboard the International Space Station in 2023.

Susan Karlin is an independent journalist based in Los Angeles. Her stories have been published in Wired, Scientific American, and the New York Times, and she writes frequently about the future of transportation.