Head Skunk

Kelly Johnson was a giant in aircraft design. On the 100th anniversary of his birth, we find out how his legend grew

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Kelley_Flash_History_FM10.jpg)

The name of the super-secret project was Suntan. It was to be the ultimate reconnaissance airplane, flying so high and so fast—it was to cruise above 100,000 feet at Mach 2—that detection would be unlikely and interception impossible. But it also would have been a giant winged thermos bottle, with a fuel tank full of liquid hydrogen at –400 degrees Fahrenheit and its outer skin baking at 350 degrees or more. A proposed hydrogen liquefaction plant dedicated to producing fuel for several of the airplanes would have sucked up 10 percent of the natural gas supply of Los Angeles in two years. Flying the highly unstable and explosive liquid to the airplanes’ bases would have required a fleet of heavy transports. An accident with one of the transports would have made the Hindenburg disaster look like a campfire.

It was too much, even for the formidable head of Lockheed’s Hogwarts-like Skunk Works. Kelly Johnson had accepted the U.S. Air Force challenge in 1956 with his customary take-no-prisoners determination; now, two years later, he had changed his mind, and he told the Air Force that he thought the program ought to be scrapped.

And so it was. If Kelly Johnson couldn’t do it, the Pentagon reasoned, it couldn’t be done.

Clarence Leonard Johnson was born in 1910, the seventh of nine children, in Ishpeming, on Michigan’s Upper Peninsula. His family, Swedish immigrants, was poor; their lives were only a step or two above those of frontiersmen. His mother took in laundry and the young Clarence sometimes delivered the wash on his wagon or sled. Ashamed of his family’s poverty, he kept to the back alleys on days when the streets were crowded. “I vowed that one day I’d return to Ishpeming not on the back streets but the best streets,” he wrote in his 1985 autobiography, Kelly: More Than My Share of It All.

Johnson was an American stereotype: the poor but hard-working lad who makes his way to the top. Smart, talented, and intensely ambitious, he possessed the fleet-footed self-confidence of gifted youth. To be a character in a movie, he lacked only good looks; later in life he would be described as resembling W.C. Fields but without the sense of humor—not entirely fair, since he did have, though he seldom employed it, a dry and somewhat sarcastic wit.

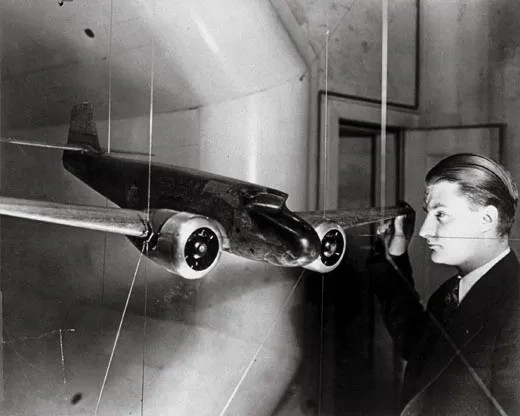

Attending the University of Michigan on scholarship, Kelly Johnson—he had acquired the nickname in grammar school—studied aeronautical engineering and made spending money by developing streamlined bodies for various clients, including Studebaker, in the university’s wind tunnel. In 1933, during his final postgraduate year, he and his professor, Edward Stalker, evaluated a model sent from the small California firm of Lockheed. Stalker judged the stability of the twin-engine, 10-seat airliner acceptable; Johnson disagreed. But the standards of the era were lax, and a university wind tunnel was perhaps loath to issue verdicts that would alienate clients.

After getting his master’s degree, Johnson went to work at Lockheed as a tool designer. Ignoring elementary principles of office politics, he immediately informed the chief engineer, Hall Hibbard, that his Model 10 Electra was dangerously unstable. Johnson must have reeled off enough coefficients, and shown a strong enough grasp of practical aerodynamics, to make Hibbard suppress any impulse to fire the upstart on the spot. Instead, Hibbard sent the young apprentice back to the Michigan wind tunnel with the big Electra model crammed into the back seat of his car.

In a series of wind tunnel tests, Johnson removed the model’s large wing-root fairings and replaced its central vertical fin with smaller ovals set at the tips of the horizontal stabilizer. A natural arrangement for a twin-engine airplane, the design had been used before; it ensured that if one engine failed, the slipstream of the other would be blowing over one rudder, helping to keep the airplane flying straight.

Johnson’s modifications solved the airplane’s stability problems, and he returned to Burbank a hero. Leaving tool design behind, at 23 he joined the ranks of Lockheed’s five other aeronautical engineers.

Despite his brashness, Johnson had a nerdy side. In his spare time he took classes at the California Institute of Technology, and he amused himself during vacations by solving practice problems in calculus and engineering textbooks. But he was also a flight-test engineer—the person who collects data during test flights—who joked that he needed one good scare a year to keep in touch with what he called “the concern of the pilot”—namely, staying alive.

Loughead Aircraft Manufacturing Company, founded in 1916 and renamed Lockheed 10 years later, had thrived during the 1920s by building fast, powerful airplanes for customers like Charles Lindbergh, Roscoe Turner, Jimmy Doolittle, and Wiley Post. Some of Johnson’s time was spent supporting the technical needs of the company’s celebrity clients. One of them was Amelia Earhart; the airplane in which she disappeared was a Model 10 Electra, and she and Johnson experimented with weight and balance, power settings, mixture, and altitudes to get maximum mileage per gallon. Later, when Lockheed developed the Constellation for Howard Hughes’ Transcontinental & Western Air, Johnson would have more contact than he wished with Hughes, whom he detested and, incidentally, considered a dangerous pilot.

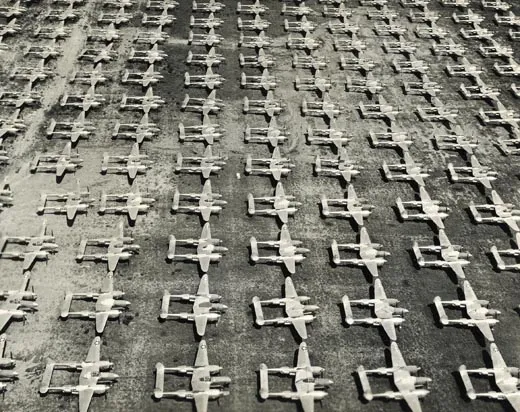

In 1937, the Army Air Corps published a specification for a high-altitude interceptor; Lockheed responded with a proposal for what was to become the P-38. Its twin-boom configuration, which is usually credited to Johnson although it could hardly have been adopted without the participation of Hibbard, was unusual but logical. As Johnson later pointed out, the amount of stuff—engine, radiators, landing gear, and turbo-supercharger—that had to go into the engine nacelles made them so long that, given Lockheed’s fondness for twin vertical tails, it made sense to extend them another five feet to carry the empennage. The P-38 Lightning was Johnson’s second big success; eventually, nearly 10,000 of the fighters were built.

Early in 1938, several Lockheed executives traveled to England to pitch a militarized version of the Model 14 Super Electra to the British, who were hastily restocking their armories. The executives took Johnson with them. The British were interested, but they wanted major changes. Working through a 72-hour holiday weekend with almost no sleep, Johnson redesigned the airplane and had weight, performance, and cost estimates ready on Tuesday morning. Though impressed, the Chief of the Air Staff, Sir Arthur Virnay, privately demanded the personal assurance of Courtlandt Gross, the Lockheed group’s ranking executive, that the analyses of his 28-year-old designer could be relied upon. In those days, personal assurances meant something; days later, the Air Ministry ordered 250 airplanes. At the time it was the largest order ever placed with an American manufacturer. That year, Johnson was named chief research engineer.

Not only a designer and engineer, Johnson was a salesman as well, and an energetic promoter of himself and his ideas. He knew how to dominate meetings, even among military people who were themselves professional dominators. He became well known to the general staff of the U.S. Army Air Corps and Air Forces—the name changed in 1941—securing their confidence as much by his manner as by his achievements.

But he was still merely human. It was not until five years later that the Kelly Johnson of legend, the Superman of aeronautical engineering, came into being.

In 1943, the USAAF was becoming concerned about Germany’s development of jet fighters far superior in performance to anything the Allies had. A timid initial American experiment with jet propulsion, the Bell XP-59, had yielded an uninspiring airplane whose performance was inferior to that of propeller-driven types. Lockheed proposed a jet engine and airframe, and when Johnson promised the commanding officer of Wright Field in Ohio a jet airplane in six months, he had a letter of intent in hand within hours.

Johnson flew back to Burbank to present the project to Lockheed president Robert Gross. The company was working for the war; with three shifts a day, six days a week, it produced 28 airplanes daily. There was no space and there were no people for another project. But Gross, who thought Johnson walked on water, okayed the project and put him in charge of it.

Johnson went around the factory collecting people: “I simply stole them,” he later wrote. He set up a secret shop beside the wind tunnel in a space walled with wood from Hudson engine crates and roofed with a circus tent. Once the facility had been set up, the time remaining for actual design and construction of America’s first jet fighter was 150 days. This was not impossible; North American had designed and built the P-51 Mustang prototype in even less time. Johnson’s team beat the deadline—and the budget—with what would become the P-80 Shooting Star.

That was the beginning of the Lockheed Skunk Works, from which would emerge the F-90, F-94, F-104, and U-2, as well as a number of less-than-secret projects for which, during slack periods, the Skunk Works would produce prototypes. The Skunk Works put Johnson into a unique position among airplane designers. He may not have been more talented or insightful than the great designers at rival companies, but he now deployed his considerable managerial abilities within a secret castle in which his supremacy was unchallenged. His protected position and intimidating personality had the effect of funneling all his subordinates’ talents and achievements through him. Ben Rich, who went to work for Johnson in 1954 and became his protégé and successor, remarked that one thing you had to get used to at the Skunk Works was that all the airplanes were Kelly’s airplanes. The story of the giant brain performing wonders in secret, like the Wizard of Oz, is an irresistible one, and over time Kelly Johnson became as much a myth as a man. “Kelly Johnson was my childhood hero,” says Daniel Raymer, former head of advanced design at Lockheed. “I wanted to be either him or Tom Swift when I grew up.”

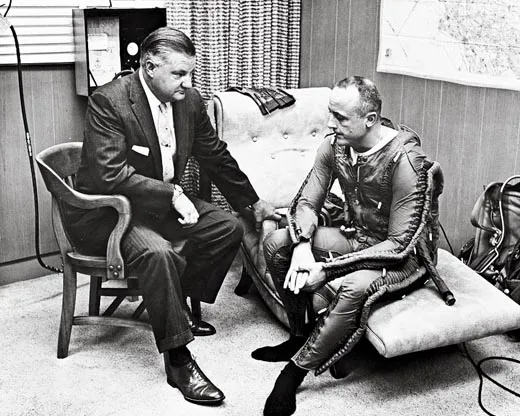

By 1958, the Central Intelligence Agency had been flying the U-2 for two years. But the big spyplane was too easily detected by radar, and its only protection against fighters and missiles was the 75,000 feet at which it cruised. A study of factors affecting radar visibility—these were the earliest days of stealth—had concluded that, because a faint, slow-moving blip became brighter with each successive sweep of a rotating antenna, a very fast airplane with low radar reflectivity would leave only a faint trail of widely spaced dots on a radar screen, and so stood a good chance of escaping notice.

The hydrogen-fueled Suntan project having been euthanized, the CIA now requested a conventionally fueled airplane of similar performance: Mach 3-plus cruise for 4,000 miles at extremely high altitude.

Under the internal name Archangel, Lockheed’s ADP division—“Advanced Development Projects” was the official name of the Skunk Works—bounced around a seemingly random series of designs powered by jets, rockets, and ramjets or, in one case, all three. None of them was capable of the required speed, height, and range. Engineers might have dropped the project in frustration, except that at the time the Skunk Works had little else to occupy it.

ADP’s ideas eventually converged, however, on a delta with two big jet engines and an extremely long fuselage with a peculiar cross-section. Both this design and the Convair division of General Dynamics’ Kingfish—a delta with a faceted fuselage ahead of its time—were presented to a CIA/Air Force/Department of Defense panel in August 1959. Both airplanes promised Mach 3.2 cruise at 85,000 feet. Although Convair’s design looked good and the company had the experience of developing the supersonic-cruise B-58 Hustler, the contract went to Lockheed. The reasons for the decision aren’t known, but the overriding one was undoubtedly the confidence of the CIA’s “black operations” honcho, Richard Bissell, in Kelly Johnson, who was then at the zenith of his engineering powers and managerial skill.

The design presented two unprecedented challenges: aerodynamic heating—at the Blackbird’s 2,000-mph cruising speed, the friction of air would soften and crumple an aluminum airframe—and making jet engines run at 80,000 feet, where the atmosphere has only one-sixteenth the density it has at sea level. Most aircraft projects, even pioneering ones, involve known materials and techniques, and make some use of the proven features of their precursors. The Blackbird was without antecedents. It required basic research in the fabrication of a new structural material, titanium; new fuel and lubricants; new fittings, wiring, and insulators; new sealants and fasteners; new nacelle designs and airframe aerodynamics; new ways to defeat radar; and new environmental systems to keep the pilot from roasting in his seat. The Blackbird remains, 50 years later, the highest performing jet airplane ever built: Nothing else has ever equaled its combination of speed, altitude, range, and, incidentally, spectacular good looks.

Kelly Johnson’s Skunk Works was a revolt against the formalities of conventional industry. It was a throwback to a time when airplanes were created by small teams who all broke for lunch together. Johnson crammed a small number of capable people into close proximity, so that “engineering shall always be within a stone’s throw of the airplane.” He believed in the freewheeling inventive genius of individuals—particularly himself; he resented the intrusions of committees of government bureaucrats with their meddlesome meetings, and rebelled against their minutely detailed specifications.

He pared away procedural dross: Whatever used up time without advancing the project was banned—even visits from the customer. Finished drawings were not required; shop men were encouraged to work from sketches and when possible to develop parts directly on the airplane. Decisions, once made, would not be second-guessed; good enough was good enough. Meetings were limited to two or three essential participants. Initial flight tests would be conducted by the builders—not, as was usual at the time, by the customer’s pilots.

To the extent that an organization could, the experimental shop would behave like a single person. Its soul was Johnson, pushing, demanding, worrying, inventing. “Kelly’s ghostly voice nagged at me during the fifteen years I occupied his big corner office,” wrote Ben Rich in his memoir Skunk Works. “I always thought of the place as his, because his personality and character were branded on everything we did.”

While the Skunk Works is usually viewed as a unique creation of Kelly Johnson’s, it was so only in the context of a bloated American aerospace industry. France’s Marcel Dassault used small, elite staffs in the same way that Johnson did, developing the Mirage IV supersonic bomber with a design team of fewer than 100. The revolutionary vertical-takeoff Hawker P.1127, which became the Harrier, emerged from a similar-size team of designers. Compared with the British or French, American firms typically employed two or three times as many people on a project.

The omniscient Johnson understood each man’s job. He once scribbled in a project log, after visiting his engineers to determine what problems they were having, “Most engineers considered they didn’t have any, but after I suggested four or five each, they agreed.” Some found him inspiring to work for; some found him tyrannical. Ray Goudey, a test pilot who also often flew Johnson in the company’s jet, remembers him as “fun to be with.” John Benson, who was head of propulsion at Lockheed during the Johnson era, recalls that the great man could make his staff uneasy: “I was in his office more than I wanted to be. He was a demanding person. I knew Ben [Rich] from way back and saw him as a friend, but not Kelly.”

Given to displays of temper, Johnson used firing as a rhetorical device; one engineer claimed to have been fired several times in one day. Yet Johnson was tolerant of errors; what mattered was not that you had made a mistake, but what you did about it. His people were the best, and most were fiercely loyal to him. “I’m not sure how he picked his team members,” says Steve Justice, who maintains Lockheed’s archive of Kelly Johnson papers. “But he batted about .950. Without Kelly they didn’t exist—and without them, he didn’t.”

Ben Rich described Johnson’s ability to predict a temperature, weight, or pressure instantly and accurately, unlike others, who could only arrive at the numbers by long calculations. Johnson kept a bunch of quarters on his desk—they stood in for the proverbial chip on his shoulder—to pay off on a standing bet that if any of his engineers disagreed with him, Johnson would be right. Few quarters left his desk.

Johnson was not always right, but it did not always pay to prove him wrong. On the maiden flight of the U-2, Johnson instructed pilot Tony LeVier to land the tandem-wheel airplane on its front gear. LeVier tried several times, and each time the airplane bounced and started to porpoise. Finally, when the light was failing and rain was moving in, he did it the way many pilots familiar with tailwheel airplanes would: He landed nose-high, the tailwheel touching first. It worked. At the first-flight celebration that evening, Johnson, who was a big man and strong, challenged LeVier to arm wrestle. Johnson won easily, then banged LeVier’s hand against the table so hard that the pilot showed up for work the next day with his hand bandaged. A tipsy accident, perhaps, or perhaps just Kelly Johnson being sure he had the last word.

For the U-2, because of the extreme secrecy surrounding it, the Skunk Works expanded to become a production facility as well, and thereafter it sometimes handled the overflow from Lockheed's “white world” projects. Today, it is difficult to tell the extent of Johnson’s participation in Lockheed’s many aircraft. Lists of “his” airplanes often include the Constellation, on which he collaborated with Hall Hibbard, and the YC-130 Hercules, which he did not design and in fact disliked. “After Kelly started the Skunk Works,” says John Benson, “he didn’t do the designs himself, he just had considerable input as to the aircraft’s design features. So he got the credit.”

Johnson’s crown jewel, the Blackbird, was, like any big airplane, a team effort. In his book, Rich describes the frenetic push to come up with the final proposal, and, as if to correct the notion that everything sprang fully formed from Kelly Johnson’s head, he names a dozen engineers and the designs for which they were responsible. Regardless of how much came from others, however, the Blackbird is always said to have been “designed by Kelly Johnson.”

Johnson was married three times. His first wife, Althea Young, was an assistant treasurer in the accounting department at Lockheed—she handed out the paychecks—when he went to work there. They were married in 1937; she died in 1969. The next year, Johnson, by his own account a “worry-wart” who had suffered from ulcers all his life, had part of his stomach removed, leaving angina and heart attacks as his main health problems. In 1971 he married his secretary Maryellen Meade; a diabetic, she died in 1980 after a long illness. Within weeks, Johnson, after consulting Ben Rich about the propriety of doing so, married Maryellen’s friend, Nancy Horrigan.

Johnson had a busy life outside Lockheed. He and Althea built a house in Encino, in the San Fernando Valley, 10 miles west of Lockheed’s facilities. They kept horses, and eventually acquired a working ranch, Star Lane, in the Santa Ynez Valley, north of Santa Barbara. Johnson maintained his own farm machinery in a 4,800-square-foot shop that he had built, and whose huge size and strong construction were a source of pride for him.

Johnson never had children. Ben Rich, however, was something like a son to him. Rich’s son, Michael, remembers Johnson as an amiable friend of the family: “He came with us to Dodger and Little League games. I didn’t have the feeling that I was with a famous person. Later my dad told me: There were not many titans like this.”

By 1972, when Lockheed’s proposal for a lightweight fighter—essentially a rework of the F-104—was rejected in favor of General Dynamics’ F-16, the days were over when Kelly Johnson could pitch a vaguely defined airplane to a general and have a letter of intent handed to him. His powers as a salesman, which had served him so well at the Pentagon and the CIA, were of little use in a world where, as Ben Rich wrote, “ideas were…a one-way street, initiated by Air Force planners with doctorates in flight sciences.”

Johnson retired in 1975, but remained a consultant and personal advisor to Ben Rich for years. He disliked Rich’s first big success, the F-117 stealth fighter, as did most of Kelly’s old guard. Kelly, says Steve Justice, “didn’t like ugly.”

In 1983, “60 Minutes” ran a segment on Johnson. He was 73 then, a grandfatherly figure, his old fierce energy tempered or concealed. He answered Morley Safer’s naïve questions decisively, and volunteered the opinion that the most important airplanes of all were cropdusters—a type he had never designed—because they made it possible to feed the world. Uninformed viewers could not have guessed what a colossus this amiable codger had once been.

A catch, a stammer in his voice in that interview was perhaps the first sign of the dementia that would soon begin to devour him. Three years later, he fell and broke his hip. He never left the hospital after that. Increasingly eroded by senility, he lived another four years. The towering Kelly Johnson of legend faded slowly away; he died on December 21, 1990. He was buried in the foothills south of Burbank Airport, where his career began. There he sleeps, and the jets wheel overhead.

Peter Garrison’s last feature on legendary engineers was about Richard Whitcomb (June/July 2002).