Jimmy Wyld, the Young Genius Who Jump-Started the U.S. Rocket Business

Seventy-five years ago, a bunch of amateur rocketeers from New Jersey started a small company with a big future.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/d4/d3/d4d31c91-5c61-4a6f-9a66-813f81352f79/wyld_selfie.jpg)

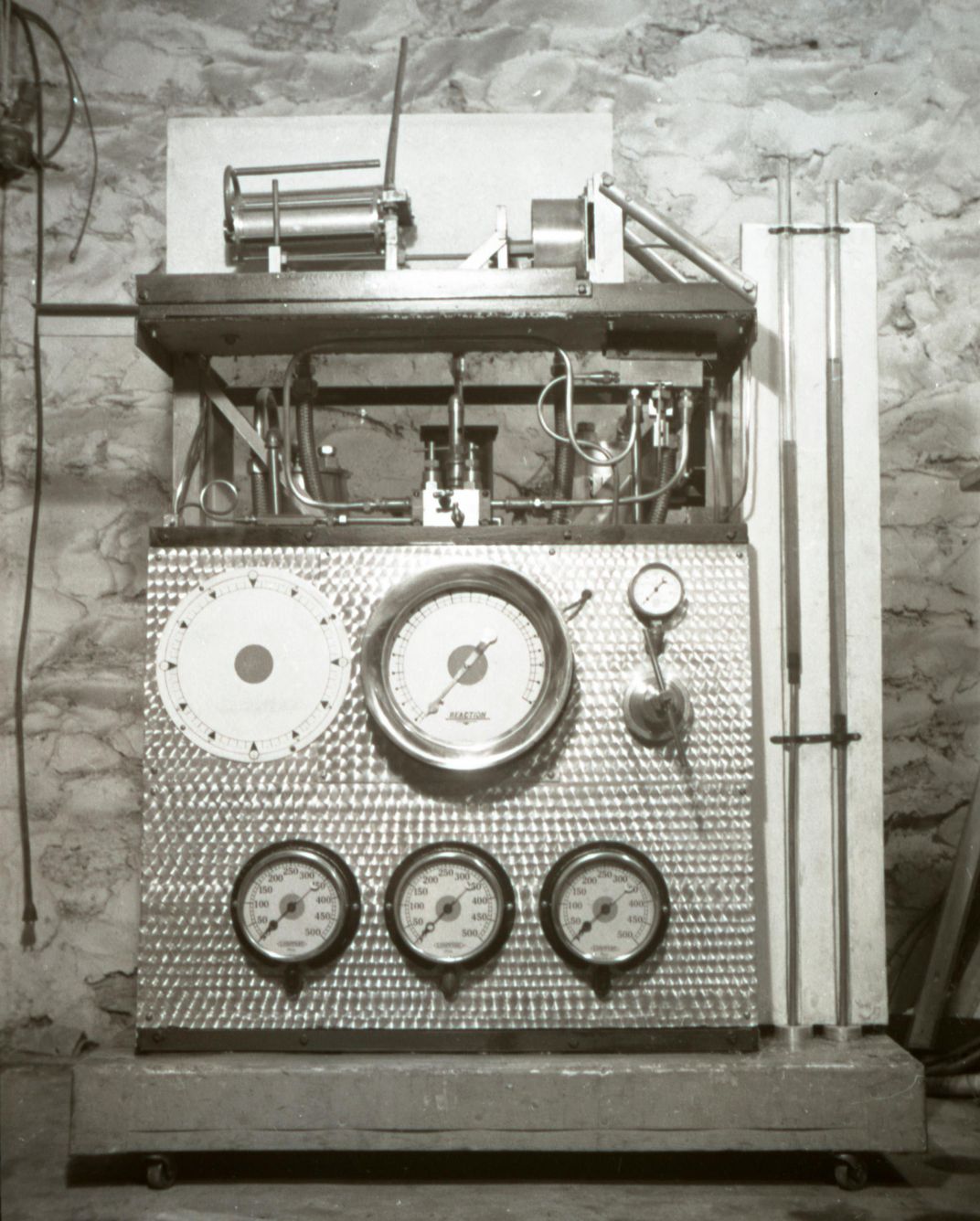

On the cold and drizzly afternoon of December 10, 1938, a momentous event in American aerospace history took place, although no one likely would have recognized it at the time. On that day James H. “Jimmy” Wyld conducted the first static test of his regeneratively-cooled, liquid-propellant rocket motor, using a crude, portable test stand owned by the American Rocket Society. The stand was set up against the stone foundation of an unfinished house in New Rochelle, New York, just outside New York City.

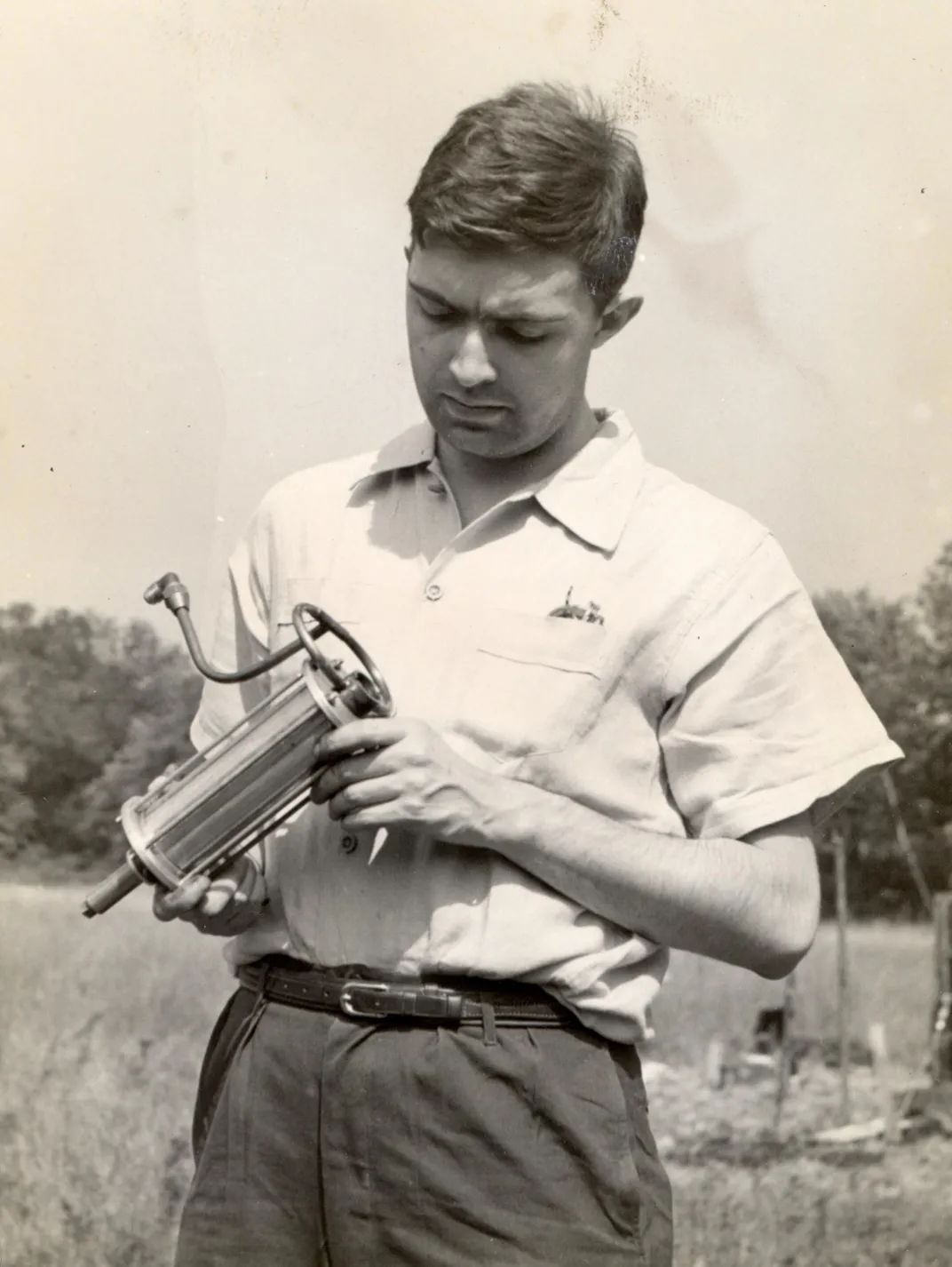

In those days, the ARS was the leading amateur rocket group in the country, despite having less than $50 in its treasury. Wyld, an exceptionally bright and technically gifted 26-year-old member of the society’s Experimental Committee, had caught the rocket bug at the age of 19 after reading David Lasser’s Conquest of Space, the first English-language book on the topic. He joined the ARS in college, and from that point on was totally hooked on rocketry, which he added to his other interests, ranging from astronomy to aviation, TV electronics, photography, and even magic. Although he had graduated from Princeton in 1935 with high honors and a degree in mechanical engineering, Wyld had a difficult time keeping a job during those Depression years.

In 1938 the Experimental Committee was still struggling with tiny rocket motors that overheated, and sometimes exploded, after only seconds of firing. Robert Goddard, the eminent American rocket scientist, had been working on similar problems, but was so secretive that the ARS knew nothing of his experiments. Wyld, however, knew of work being done in Europe, and learned German and French in order to read the few existing technical works on rocketry by pioneers such as Hermann Oberth.

A consummate engineer, he also painstakingly began to work out a method of cooling rocket motors to make them more practical, if not for spaceflight then for meteorological measurements in the upper atmosphere. Wyld most likely came up with his “regenerative cooling” approach—which used the rocket’s own fuel to regulate temperatures—sometime between late November 1935 and January 1936. Although others in Europe had hit on the same technique, and Goddard had tested (then abandoned) a regeneratively-cooled motor as far back as 1923, the members of the ARS were unaware of these mostly secret efforts.

Wyld’s concept was deceptively simple: a “cooling jacket” was to surround the rocket combustion chamber; this was an outer cylinder with an empty space between it and the chamber. The rocket fuel (alcohol) was circulated inside the jacket, then injected into the combustion chamber, where it met an incoming stream of supercold liquid oxygen, or LOX, to provide the oxygen needed for combustion. A spark plug ignited the mixture, producing combustion gases that exited from an exhaust nozzle to propel the rocket.

Wyld’s regenerative system was designed to cool the motor while it was running and also pre-heat the fuel, which added to the efficiency of the motor. He worked out all the complex mathematical calculations of heat-flow, exhaust velocity, and other factors to satisfy himself that he was on the right track before creating a prototype.

Then, very slowly, he built the motor, using a small lathe in his spare Greenwich Village apartment. The pint-sized, hand-held motor, weighing about two pounds, was finally finished by September 1938, around the same time Test Stand No. 2, which Wyld also had helped design, was completed.

“You can imagine how excited I was when we fired up, how excited everyone was to see how this radical and much-discussed motor would behave,” Wyld wrote to a friend the day after the first test on December 10. “On opening the valves, a long, crackling, diffuse yellow flame some eight feet long shot from the nozzle.” After the test run, he continued, “Amid the greatest excitement we examined the motor...To our great delight, it had not only not burned out, but was perfectly untouched!...It was impossible to tell that the motor had fired....” He wrote another friend that the firing “proved a most striking and unequivocal success—the value of the principle [of regenerative cooling] is proven beyond any possible doubt.”

Longer-duration tests were still needed, but due in part to Wyld’s continuing problems in finding steady employment, his motor wouldn’t be tried again until the summer of 1941. In two tests, the little Wyld motor performed outstandingly, reaching 135 pounds of thrust for 45 seconds—a new record—in the last test.

Then came Pearl Harbor, on December 7, 1941. Only a few days later, on the 18th, three other ARS members—Lovell Lawrence Jr., John Shesta, and Franklin H. Pierce—teamed up with Wyld to form Reaction Motors, Inc., with the intent of commercializing his invention for the war effort. RMI, whose 75th anniversary is this month, thus became America’s first liquid-fuel rocket company.

The U.S. Navy was the new company’s first and main customer. The first assignment was to develop a JATO (Jet-Assisted-Take-Off) unit to boost heavily-loaded seaplanes flying in the Pacific theater. The JATO wasn’t used for that purpose, as it turned out, although RMI did develop rocket motors for some of the earliest U.S. missiles. A far greater triumph—in which Wyld participated—was developing the 6,000-pound thrust engine for the Bell X-1 that Chuck Yeager flew on the world’s first supersonic flight on October 14, 1947.

Originally based in tiny Pompton Lakes, New Jersey, RMI expanded over the years, eventually developing the 20,000-lb thrust engine for the Viking sounding rocket. In 1950, the ship-launched Viking No. 4 became the first U.S. single-stage rocket to reach space when it soared to an altitude of 105 miles. Viking No. 11 set a new world’s altitude record of 158 miles in 1954, and took some of the first photos of Earth from space.

In 1958, RMI merged with the Thiokol Chemical Corporation to become that company’s Reaction Motors Division (RMD), and shortly thereafter developed the 57,000-lb thrust engine for the X-15 rocket plane. The company’s last major project reached the Moon. RMD had developed the small vernier motors for the robotic Surveyor spacecraft that scouted out potential sites for the later Apollo astronaut landings. The verniers took care of mid-course corrections as well as final adjustments for soft touchdowns on the lunar surface. On June 2, 1966, Surveyor 1 made America’s first soft landing on the moon, as well as the nation’s first landing of a spacecraft upon another celestial body.

RMD finally closed its doors in 1972, mainly due to stiff competition from larger rocket engine manufacturers like Rocketdyne. But Jimmy Wyld’s tiny 1938 “re-gen” motor had helped America’s space program make giant strides. No surprise, then, that a crater on the far side of the moon is named in his honor.

For a more detailed account of Reaction Motors, Inc., consult Frank H. Winter and Frederick I. Ordway, III, Pioneering American Rocketry: The Reaction Motors, Inc. (RMI) Story, 1941-1972 (Univelt, Inc.: San Diego, 2015), 462 pp. Winter is presently completing an abridged and updated version of the history of RMI, to be published in 2017 by the AIAA (American Institute of Aeronautics and Astronautics).