Know Which Way the Wind Blows

Know Which Way the Wind Blows

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Perfect-Wind-Storm-sidebar-FLASH.jpg)

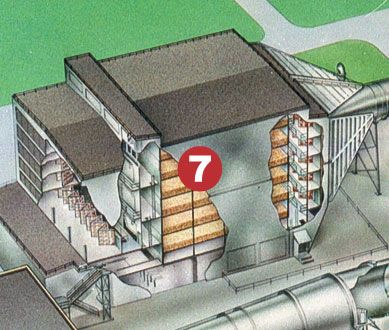

In the early days of flight, wind tunnels were as unsophisticated as the airplanes they tested. Put a box fan in a circuit of ductwork and you’ll have a pretty good representation of an early wind tunnel.

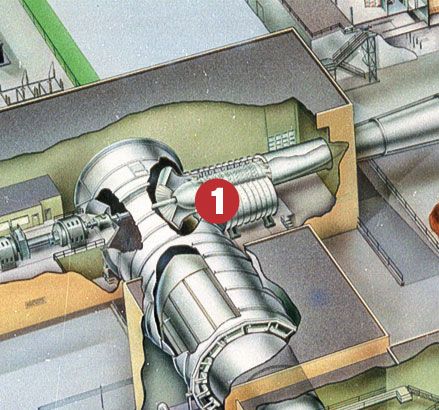

Arguably the most important advancement, as well as the most critical component, was the converging nozzle, which modestly accelerated airflow. You can accelerate the airflow from a fan or compressor by constricting the area the air is flowing through. But regardless of the number or power of tunnel compressors working to increase airflow, the fastest speed the early tunnels could achieve was Mach 1.

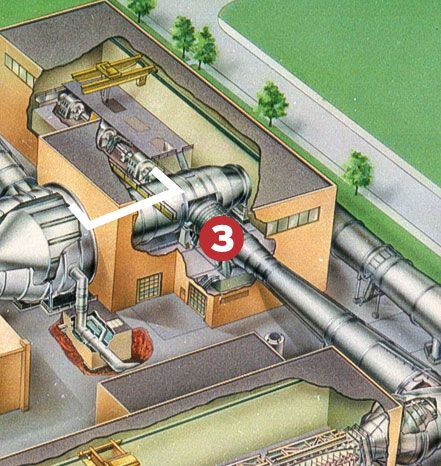

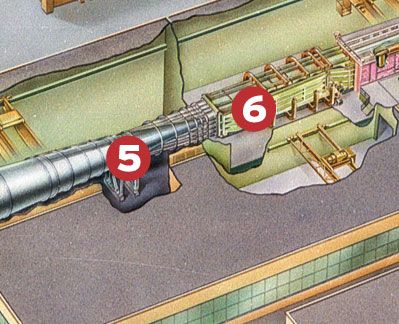

The nozzles were being “choked” by a shock wave sitting in the nozzle throat. Rather than try to get around, or get rid of, the shock, engineers employed an aerodynamics principle that was then little used. In subsonic wind tunnels — the type you might see your local TV weatherman strapped into during hurricane season — the air speeds up through a constriction and slows down through an expansion, which is why the test section — where the model (or the weatherman) sits — is located at the throat of the nozzle, where the wind speeds are maximum. But something peculiar happens when air goes supersonic: the phenomenon reverses. Supersonic air suddenly acts like cars in heavy traffic, slowing down when constricted and speeding up when given more room to flow.

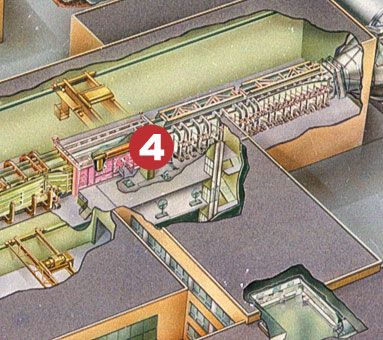

Tunnel engineers take advantage of this reversal by constricting flow in the convergent half of the nozzle until the air reaches sonic speeds (at the throat), then expanding the flow in the divergent half of the nozzle to accelerate the flow to supersonic speeds. With the highest wind speed no longer in the throat, the test section is moved further downstream, where supersonic flow is fully achieved. The wind speed in the test section is then dependent on the conditions in the divergent half of the nozzle: the greater the difference in area between the throat and the 10- by 10-foot test section, the greater the airspeed. Want to boost wind speed from Mach 2 to Mach 3? Squeeze the nozzle further. Doing so exacerbates the difference in area between the throat and the test section, thereby expanding the Mach 1 flow at the throat even more and increasing speeds in the test section. In the 10 x 10, hydraulic jacks are calibrated to place the stainless steel walls of the nozzle to within 0.005 inch of the needed shape. The speeds are then limited only by the amount of back pressure the compressors can handle. Constrict the throat too much and the fans supplying air will stall, leaving you with a wildly overpriced blow dryer.