Leaping Lunar Landers!

Can a spacecraft hop its way to winning the Google Lunar X prize?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Leaping_Lunar_Landers_0911_1_FLASH.jpg)

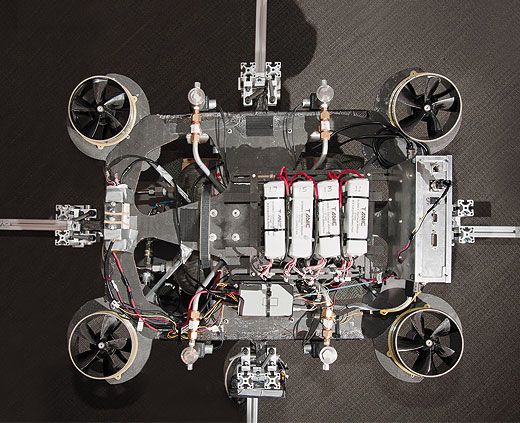

In a windowless two-story room in a Cambridge, Massachusetts laboratory, a contraption of carbon fiber and plywood dangles from a crane in the ceiling, three feet from the floor. The machine is about three feet across, and at each corner, ducted fans point down, at an outward angle of about 30 degrees. They are silent now, but when running, their function is to counteract five-sixths of the pull of Earth’s gravity and allow the machine to simulate operations in the moon’s 1/6 G.

This is the Terrestrial Artificial Lunar And Reduced gravIty Simulator, or TALARIS. It’s the latest in a series of prototypes built to perfect the technologies for an unusual planetary rover, one that hops from place to place instead of traveling on wheels, the more common way planetary rovers move. A team of students from the Massachusetts Institute of Technology and managers at Draper Laboratory, where the machine is under development, are preparing TALARIS for a test.

After graduate student Christopher Han reads off a safety checklist, everyone retreats behind Plexiglas-and-plywood shielding, where another student, Christopher Rossi, mans a laptop. Draper manager Bobby Cohanim stands at a lanyard, ready to keep the ropes securing TALARIS to the crane from getting sucked into the ducted fans. A thrown fan could present a serious hazard, as could the pressurized tanks under the vehicle, if punctured. Hence the shielding, and the safety glasses everyone wears. The team members also wear big yellow over-the-ear protectors to prevent the roar of the fans from causing hearing loss.

“IMU calibrating,” calls out Rossi. Then “Five seconds till fire.” Five seconds later, the fans spin up, sounding like an industrial vacuum cleaner. The torque they produce gently twirls the vehicle stage right, according to plan. Next, cold-gas thrusters—used in place of the rockets of an actual space vehicle for greater safety in Draper’s indoor lab—begin firing nitrogen with an angry hiss, the on-off pulses that modulate the thrust happening much too quickly for the human ear to distinguish.

What happens next is definitely not according to plan. The vehicle begins to yaw, swinging with increasing intensity. Rossi quickly hits the command to shut it down. The pressurized tanks hold enough gas for some 30 seconds of operation, but this test ends after only 10 seconds. Han steps out from behind his Plexiglas shield and, using a wooden pole, smacks the big red emergency kill switch on the top of TALARIS. Once Han is out of the way, Rossi sends the command to dump the nitrogen remaining in the lines feeding the thrusters. One final hiss and a jolt, and the vehicle is safe to approach.

Grad student Sarah Nothnagel holds a remote-control kill switch. “I didn’t know whether to kill it or not,” she says.

“Once there starts to be growing oscillations, it’s done,” says Cohanim as he removes his safety goggles. The team will have to rebalance the precise intervals and durations of the cold-gas thrusters’ firing.

THE CONCEPTS BEHIND THE HOPPER originated in MIT’s Practice of Aeronautics class, taught by former space shuttle astronaut Jeffrey Hoffman. But the impetus for building a working prototype to gather real-world test data for an actual planetary hopper came from the Google Lunar X Prize, which offers $20 million to the first non-government team to land a rover on the moon. More specifically, the impetus for making the leap out of the classroom and into the laboratory came from former U.S. Air Force pilot Michael Joyce, leader of Next Giant Leap, one of the teams competing for the X Prize.

The 49-year-old Joyce planned on a career as an astronaut, so he joined the Air Force after college, hoping to become a test pilot. But the Challenger space shuttle disaster of 1986—and the subsequent grounding of the shuttle fleet while Joyce was still in pilot training—put his space dream on hold. After flying Boeing B-52 bombers and training other pilots to fly Northrop T-38 jets, he feared that his dream of joining the astronaut corps was a long shot and that he was facing a desk job. So he left the Air Force and sought another way to scratch his space itch.

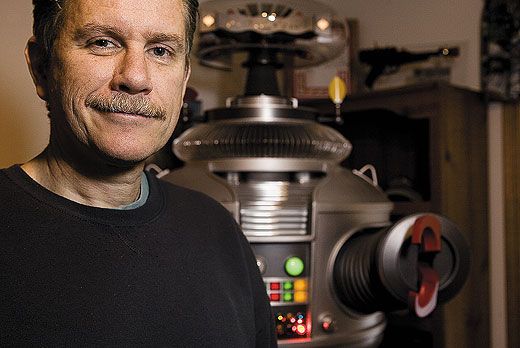

He turned to science fiction, starting a business building full-scale replicas of the robot featured in a TV show he loved as a kid: “Lost in Space.” Each six-and-a-half-foot-tall robot, built in the basement of his home in the Black Hills of South Dakota, features a 240-watt built-in stereo system, which plays new vocalizations by the original robot’s voice actor. Joyce’s robots retail for $24,500, and his customers are mainly fellow “Lost in Space” fans who became successful in tech careers. “I am very moved that I am now able to fulfill my boyhood dream of owning my very own B9 Robot thanks to your company,” says a typical testimonial on the Web site of Joyce’s company, B9 Creations. Joyce has sold more than 50 robots.

The announcement of the Google Lunar X Prize in 2007 freshened Joyce’s passion for spaceflight, and his experience with the robots pointed the way toward a serious bid to win. Now adept at finding component suppliers and putting the parts together, he thought he could manage the project of building a moon-roving robot, although he didn’t know exactly what form the machine would take. “I knew I needed some team members, obviously,” says Joyce. “I knew I wasn’t a rocket scientist.”

Early in his search, Joyce found MicroSat, a Colorado company located within a day’s drive from his house. MicroSat formed the nucleus of Joyce’s technical team, particularly an engineer named Todd Mosher. In December 2008, Joyce and his new collaborators announced their intention to compete for the Google Lunar X Prize.

In discussions, Joyce and Mosher considered the concept of a hopping rover. Mosher was already friends with MIT’s Hoffman, who was independently developing the hopper idea with his students. (Hoffman says the idea grew out of class discussions and papers, and that he can’t credit any one innovator.) It was an easy sell for Mosher to bring Hoffman and his students into the project, and through them the closely affiliated Draper Laboratory.

With the 2009 purchase of MicroSat by Sierra Nevada Corporation, a rising star in spacecraft, satellite, and rocket development, Next Giant Leap gained an important new ally. Sierra Nevada’s most ambitious project is a seven-seat lifting-body spaceship known as Dream Chaser. In 2011, NASA, which is seeking replacements for its retired space shuttle fleet, gave Sierra Nevada $80 million to develop Dream Chaser as a reusable transport for missions to low Earth orbit. Mosher now oversees the program.

Joyce and Mosher plan to build their moon-hopping spacecraft around Sierra Nevada’s new standardized satellite bus, developed for the satellite communications company ORBCOMM. Eighteen of the satellites are under construction at Sierra Nevada’s factory in Louisville, Colorado; they are all bound for low Earth orbit as tracking and data communications relays for the shipping industry. If Joyce and his crew of experts are successful, one additional satellite will go much farther.

But first Joyce, like all of the X Prize competitors, will have to raise tens of millions of dollars, much of it from investors who will expect to see a return on their investment. In other words, Joyce will have to support his lunar aspirations by establishing a sustainable business.

Fostering the commercial development of space is one of the goals of the Google Lunar X Prize. Like the original Ansari X Prize, it was created by Peter Diamandis, another would-be astronaut. Diamandis identified the cost of getting to space as the single biggest impediment to getting people like himself into the final frontier. And he believed that if the cost of getting there could be lowered, space exploration could bring financial reward. “Everything that we hold of value on this planet—metals, minerals, real estate, and energy—are in infinite quantities in space,” he’s fond of pointing out. “The Earth is a crumb in a supermarket filled with resources.”

Fellow space enthusiast and Google co-founder Sergey Brin got Google to commit the all-important prize money, a total of $30 million. To win the $20 million first prize, the first team to land a robot on the moon has to send high-definition video back to Earth, along with social media posts, and travel at least 500 meters (about a third of a mile). A second place winner accomplishing the same tasks gets $5 million. The prize must be claimed before the end of 2015, and the top-prize purse drops to $15 million if a government-sponsored lander arrives on the moon first.

Bonuses for photographing human-made artifacts already on the moon, finding water ice, surviving the two-week lunar night, and traveling more than five kilometers (3.1 miles) constitute the remaining prize money. There’s also a bonus for the team that has the most diversity among its members (the rules say “diversity of nationality, gender, ethnicity, and other factors may be considered”). No team may accept more than 10 percent of its funding from government sources: This 21st century moon race is dominated by commercial enterprises and nonprofits. The idea is to generate self-sustaining business ventures that will continue to explore space more affordably than ever before, even after the prize is won.

Next Giant Leap is one of 28 U.S. and international teams competing for the prize. A team that seems particularly well suited to the challenge is Astrobotic, based at Carnegie Mellon University in Pittsburgh and led by robotics pioneer and professor William “Red” Whittaker, along with entrepreneur David Gump (see “Red and the Robots,” Dec. 2008/Jan. 2009). The Whittaker-led Tartan Racing team won first place in the 2007 Urban Challenge robot car race, sponsored by the Defense Advanced Research Projects Agency. Whittaker plays to win, pushing his students and the handful of employees of the specially formed Astrobotic Technologies hard. Already the team has built a solar-powered rover prototype that, driven by remote control with commands delayed to simulate communications between Earth and the moon, has demonstrated traverses of well over the 500-meter minimum. Astrobotic was also the first team to put down a deposit on a launch vehicle, a SpaceX Falcon 9 rocket.

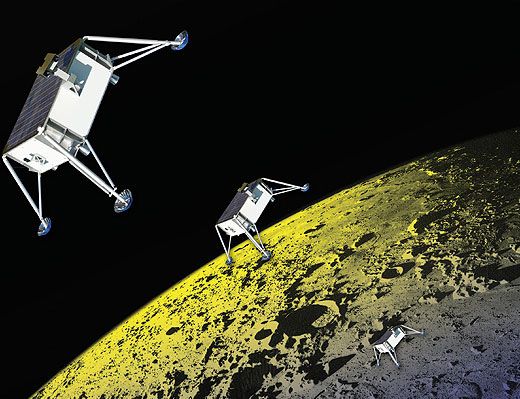

Still, Joyce and his partners feel that their rover’s hopping ability gives them significant advantages over the other teams, which all use wheeled designs. Other teams will have to build a separate spacecraft to get to the moon as well as a rover, which the spacecraft will release after landing. But in the case of Next Giant Leap, the spacecraft is the rover, or, rather, hopper. Besides having to build and test only one vehicle, the team can also greatly reduce its launch weight, and thus expense. Instead of the Falcon 9 that Astrobotic plans to use, Next Giant Leap will be able to leave Earth on the smaller and less expensive Falcon 1e (that vehicle costs $10.9 million, versus $54 million for the Falcon 9).

If all goes well with the launch, the Next Giant Leap vehicle will jettison its protective aeroshell and detach itself from the Falcon in low Earth orbit. Next it will fire and then jettison the first of three booster rocket stages to head to the moon. Five days later, the second stage will fire to insert the craft into lunar orbit. The vehicle will then use the last stage for most of the descent, jettisoning it within just a few miles of the surface to make a gentle touchdown with its onboard thrusters—small rocket motors rather than the cold-gas thrusters that were tested in the Draper lab. One of its first tasks will be to send an encrypted data package back to Earth that will include the first high-definition video broadcast, e-mail, and Twitter and Facebook posts from the moon. That accomplished, the machine will relight its thrusters to make the prize-winning 500-meter hop. Then it will make one more hop to cover the remainder of the five kilometers for the distance bonus.

According to Sierra Nevada’s Mosher, not much has to be done to his company’s standardized satellite bus to make it moon-worthy. Aside from adding landing gear, communications equipment, thrusters, and cameras, he says, the major physical modification will be the addition of the propulsion stages.

As this article went to press, Cohanim and his MIT students had gotten their terrestrial vehicle to hover for short periods and then descend smoothly. Still to accomplish were stable ascents to a hover, and long-duration hovers. A stable ascent has proven especially elusive. “It always seems like it’s just one issue away: If we solve this next issue, then we’ll be done,” says Cohanim. He attributes much of the difficulty to the spinning, vibrating ducted fans and their temperamental output. That won’t be a problem on the all-thruster lunar vehicle. Says Cohanim: “We always assumed that the lunar problem actually would be easier.”

“None of the technical challenges are insurmountable,” says Mosher. “We understand how to do this job technically. The challenge is how do you make the financial/business model work for this.”

Draper is committing $1 million for the development of the TALARIS testbed vehicle. The vehicle provides a platform for developing the guidance, navigation, and control software for Next Giant Leap. The software that enables TALARIS to use its cold gas thrusters to seamlessly transition from ascents to hovers to descents, says Cohanim, will transfer directly to the actual lunar vehicle; only the hardware will change.

The software and hardware for imaging and recognizing such ground hazards as craters and boulders and for plotting landing patterns around them, as well as for firing thrusters in finely timed bursts for precision-control flight—all will work the same way on the moon as in the lab. But SpaceX will have to be paid for the rocket launch, as will Sierra Nevada for the modified satellite bus. While the technical challenges are on their way to being solved, the financial side of the equation is daunting, especially for a team leader who isn’t independently wealthy.

Joyce is no stranger to financial risk. He bet his livelihood that a business selling full-scale versions of a 1960s TV show robot would succeed—and he won. Shooting the moon might seem harder, but he’s never been one to play it safe. “You can choose to follow your dreams,” he says. “Or you can choose to do what everybody tells you is the right thing to do—the right career move, the right job to get, car to buy, place to live. But I recommend following your dreams. There are no guarantees, of course. We might end up bankrupt here in the next few years, but I’ve never been too concerned about losing it all.”

Joyce’s major task now is to try to raise money from researchers who want to send science payloads to the moon and from corporate sponsors who hope participating in the mission will have marketing value (first logo on the moon, anyone?).

Draper’s director of space systems, Seamus Tuohy, takes the long view. He feels the hopper concept regardless of who ends up buying it, will have its day in the sun. The hopper, he says, will be able to go where no planetary robot has gone before: exploring the interiors of craters or the tops of mountains, for instance. He likens it to a kind of helicopter that will be able to explore wide regions of a planet or moon, limited only by the amount of propellant on board. Says Tuohy: “What I keep telling the engineers is this: ‘We ain’t going next year. If it’s not next year, it could be the next year, maybe the year after. We’re sowing the seeds right now that may take 10 years to capitalize on. But we’re going to look back and say that it started here.’ ”

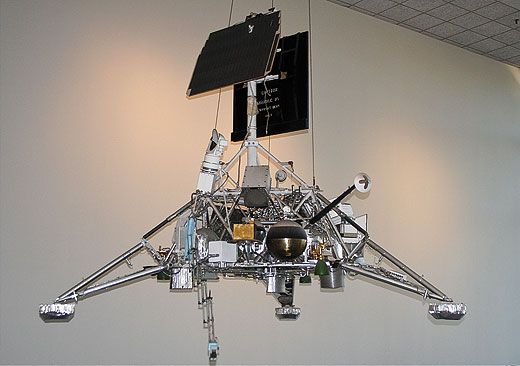

Brian Wilcox, manager of space robotic technology at NASA’s Jet Propulsion Laboratory in Pasadena, California, is a little less sanguine about robotic hoppers’ long-term viability. There’s a reason only one planetary robot in history—NASA’s Surveyor 6, in 1967—has fired up its descent engine again for a relaunch and second landing. The idea, he says, has come up throughout the history of planetary landers, and for the most part been rejected—for instance, during the Viking Mars lander program, when some engineers at JPL proposed that one of the probes use fuel remaining after landing to power a hop. The relaunch isn’t the problem, says Wilcox; it’s making another safe landing. “It’s one thing if you do it once because you have to,” he says of landing a robot on another world, “but to do it more than once intentionally seems to many people to be too risky.” Too much risk, in other words, of cracking up an expensive robot for what Wilcox sees as a limited number of advantages. Exploring the bottom of a crater or lava tube, he says, could be accomplished with less risk by a rover deploying a power and communications station at the crater rim or tube entrance, reeling out a tether behind it, and rappelling down inside.

“Hopping is a very good idea for very-low-gravity places like asteroids,” says Wilcox. “The higher the gravity, the worse it is. The moon is a borderline case because at one-sixth gravity, if you fall out of the sky, you still hurt yourself real badly, even from a not-very-high altitude.” And, yes, the winning vehicle has to survive the hop—or at least stay intact enough, say the X Prize rules, to take a “panoramic photograph or photographs to yield a full 360 degree view of the CRAFT or secondary vehicle’s location at the end of the 500 meter journey.”

Wilcox has no doubt, however, that Draper Laboratory can develop the algorithms needed for a robot that will hop on the moon successfully. This is the organization that developed the guidance, navigation, and control systems for the Apollo moon landers, after all. And he allows that hopping actually does makes sense for this one X Prize-winning mission. The Next Giant Leap concept’s reduction in weight and complexity could make the risk that hopping incurs worth taking, especially since the mission won’t involve gratuitous hopping.

IT’S LATE IN THE DAY at the Draper lab. The TALARIS team has prepped their vehicle for one final test. Actually more of a demonstration. This one is for a visiting dignitary, the commanding general of the U.S. Army’s Research, Development and Engineering Command, who has come to evaluate technologies of potential use to the Army for soldier navigation, precision air-drop systems, and…lunar hopping.

By the time Major General Nick Justice sweeps in with an entourage of officers and business-suited officials, the Draper Lab team, now looking decidedly under-dressed in their polo shirts and jeans, is ready with a hopper freshly charged with nitrogen propellant. They pass out hearing protection and goggles to the general and the others, who now crowd the space behind the plywood and Plexiglas shielding. This time the TALARIS vehicle hangs suspended from its crane some four feet off the floor.

Again the ducted fans roar to life. Again the vehicle gently spins, but only for the briefest of moments before the cold-gas thrusters rapidly pulse. This time there is no lateral motion; the machine descends smoothly, just as a future vehicle will on the moon, perhaps following a 500-meter hop. When the machine reaches the end of its tether, Rossi shuts down the fans and the thrusters. The vehicle bounces briefly and comes to rest in the sudden silence.

The general nods his approval, asks a few questions, and moves on to his next appointment. One more time, the TALARIS team safes its vehicle, and this time calls it a day, mission accomplished.

Michael Belfiore is the author of Rocketeers: How a Visionary Band of Business Leaders, Engineers, and Pilots Is Boldly Privatizing Space (Harper Paperbacks, 2008). Find him online at michaelbelfiore.com.