The Man Who Could See Air

Richard Whitcomb changed the shape of wings to come.

GREAT IDEAS ARE MYSTERIOUS THINGS. Where do they come from? Do they float down from above, launched like paper gliders by a playful muse? Or do they percolate up out of inner darkness, eventually to erupt into consciousness? Are they born fully formed, or do we construct them out of bits and pieces? Or is an idea not a construction at all but a kind of dissolution, a solvent that breaks apart things we believed to be related and allows them to recombine differently?

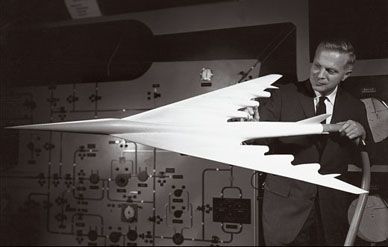

In 1951, Richard Travis Whitcomb, a slender, sandy-haired man, sits, feet up on his desk, at the Langley Research Center of the National Advisory Committee for Aeronautics in Hampton, Virginia. He wears a dark coat and a tie, and, as always, he is smoking a cigarette. He’s thinking. Suddenly, something else is there, a presence, an annunciating angel: the Idea. It’s not worked up to step by step like the answer to a long-division problem, but just there all at once. “I suddenly realized that the disturbances and shock waves are simply a function of the longitudinal variation of the cross-sectional area.”

Whitcomb’s insight was that at speeds near that of sound, the disturbances in the air produced by a complex object like a streamlined body with protruding wings would be largely equivalent to those produced by a simple streamlined body without wings, but with, in their place, a sort of midriff bulge with a frontal area the same as that of the wings. The idea was so simple that it seemed incredible that no one had had it before.

What Whitcomb’s discovery solved was nothing less than the problem of the famous “sound barrier”—the steep increase in drag and the onset of control problems that beset airplanes as they neared the speed of sound, and that, in 1951, was the principal preoccupation of the U.S. and Russian air forces and the airplane manufacturers who supplied them.

To define the problem in terms of replacing wings with a midriff bulge, as Whitcomb did in the brief secret report in which the NACA revealed the discovery to industry, was a little coy, because nobody was really interested in finding novel ways to produce the same amount of drag. What mattered was what the insight implied. It wasn’t until the last couple of pages of the epoch-making paper that Whitcomb pulled the rabbit out of his hat: If you sucked the fuselage inward in the vicinity of the wings, you could make it look to the air as if the wing wasn’t there. With a single stroke Whitcomb had severed the Gordian knot of transonic aerodynamics and cut the drag rise by half.

Whitcomb’s idea came to be known as the Transonic Area Rule, but when it was declassified and made the front page of the New York Times, the popular press dubbed it the “Cokebottle fuselage.”

At a time when jet engines were less powerful than they are today, the idea was the key to some airplanes’ ability to achieve supersonic speeds. One was the Convair F-102, a delta-wing interceptor, the prototype of which was nearing completion when Whitcomb made his breakthrough. Already committed to a conventional cigar-shaped fuselage, Convair’s management was unwilling to change the design even though Whitcomb’s analysis indicated that it wouldn’t achieve the supersonic speed the Air Force required. Indeed, it didn’t. Management’s first ploy—“It still makes me mad when I think about it,” Whitcomb bristles today—was to pressure the Air Force to accept the airplane as it was. But the Air Force wouldn’t have it; either the airplane had to go supersonic or the contract would be terminated. Finally Convair relented and built a new, arearuled fuselage. The Coke bottle F-102A accelerated through Mach 1 while still climbing.

It happened that the internal layout of the F-102, and also that of its beautiful successor, the F-106 Delta Dagger, permitted deep arearuling of the fuselage. Other designs were more tightly packaged and couldn’t be squeezed. In the case of the Republic F-105, rather than narrowing the fuselage in the vicinity of the wing, Whitcomb proposed fattening it before and after the wing—the goal being, if the total cross-section could not be reduced, at least to make the longitudinal variation of area more continuous. “The [proposed] fuselage looked like a bowling pin,” Whitcomb recalls, and Alexander Kartveli, chief designer at Republic, “wasn’t happy. He liked his airplanes to look sleek.” But when he saw the wind tunnel results, Whitcomb says, Kartveli decided the fuselage didn’t look so bad after all.

“I think that what looks good usually is good,” Whitcomb says, though the example of Kartveli illustrates the circularity of the argument: One’s sense of what looks good is, after all, conditioned by the looks of other things that have already been demonstrated to be good. But in Whitcomb’s case that rule had a deeper meaning, because Whitcomb, unlike his colleagues at Langley and most other workers in the abstruse field of transonic aerodynamics, was in a sense an artistic rather than a theoretical or mathematical thinker. He did not interpret numerically the condition of the flow he was investigating; he felt it. “He was different from anyone else. He had a physical feel for fluid dynamics—and he was very, very good at it,” says Larry Loftin, Whitcomb’s longtime boss at Langley. Anthony Jameson, a mathematical aerodynamicist who worked with him in the 1970s, agrees. “Whitcomb,” he says, “had different thought patterns.”

The difference served him well. The Transonic Area Rule had, in fact, been implicit in earlier work by other researchers, but—perhaps because they were concerned only with the purely mathematical aspects of the problem—they had somehow failed to see its importance for practical aircraft design. Because Whitcomb saw the problem and its solution in physical terms, he was the one who reaped credit for the discovery of the rule.

Whitcomb was born in Illinois in 1921. His father, who had been a balloon pilot in World War I, was a mechanical engineer specializing in the dynamics of rotating machinery. When Richard was in his early teens the family moved to Worcester, Massachusetts, where his father went to work for Norton, a manufacturer of industrial abrasives and grinding equipment. There was little camaraderie between father and son, Whitcomb recalls, but the son had his own impulse toward aeronautics. He built model airplanes and flew them in competitions, always driven by the idea that “there must be a better way to do this”—by reducing drag or increasing propulsive efficiency. He learned a valuable lesson about aeronautical engineering from rubber bands: You could get more work out of a band that was stretched straight than one that was wound up, but the mechanical apparatus to convert straight stretch into propeller spin was so complicated and heavy that it nullified the advantage. It was an important thing for a novice aeronautical engineer to grasp: Airplane design was a matter of sometimes painful tradeoffs.

When he started at Worcester Polytechnic Institute he stopped building models—“I put aside childish things”—but gained experience in experimental wind tunnel work. After graduation in 1943, he presented himself at the Langley center, looking for work. Building up its staff as fast as it could for the war, the NACA snapped him up.

The NACA’s principal contribution to aeronautics during World War II was the testing and improvement of existing designs—basically, aerodynamic cleanup. It was a conservative policy for which the agency would be criticized when the war was over and it was discovered how far the Axis had pulled ahead in original research. America caught up by collecting and importing Germans and Italians, and Whitcomb was carried forward in a torrent of aerodynamic research alongside the likes of the brilliant Adolf Busemann, who had proposed the use of swept wings for transonic flight as far back as 1935, and Antonio Ferri, the leading Italian authority on high-speed aerodynamics.

Problems of transonic flow moved to the foreground of aerodynamics research after the war and came to be the ones that would occupy Whitcomb throughout his professional life. The term “transonic” had been coined to describe the range of speeds in which the flow over the airplane was “mixed”—partly subsonic and partly supersonic (see “Home on the Transonic Range,” below). In some cases, sonic-velocity flow appeared on airplanes at speeds as low as 300 mph, but for most practical purposes the transonic region began around 500 mph—a speed that propeller airplanes could barely attain but at which jets came into their own.

Chuck Yeager nudged the bullet-shaped, thin-wing Bell X-1 uneventfully past the so-called sound barrier in 1947. The X-1 was conventionally configured, but it was a hot rod—a very small, light airplane whose powerful rocket engine consumed fuel at a terrific rate. New fighters were bigger, heavier, and, because of the state of jet engine design at the time, less powerful, and the speed of sound was still a barrier to them. It was in the context of those early efforts to build a genuinely supersonic jet fighter that Whitcomb made the breakthrough of the Transonic Area Rule, and received the National Aeronautic Association’s 1954 Collier Trophy for “the greatest achievement in aviation in America.” He had become a bright star in a normally obscure firmament. There was little jealousy or resentment among his colleagues, however, in part because Whitcomb, amiable and always generous with his time, was well liked. “He had an ego,” says Gerry South Jr., former head of the theoretical aerodynamics branch at Langley, “but he deserved to. He knew that he was good.”

In 1957, the space race began in earnest with the Russian launch of Sputnik. Responding to widespread alarm over the United States’ having apparently lagged behind its enemy, Congress created NASA in 1958. The NACA disappeared into the larger agency, and space loomed so large in NASA’s agenda that the future of aerodynamic research was in doubt.

Langley chief John Stack defended his shrunken aerodynamics directorate by focusing its research efforts on the development of a supersonic transport, then seen as the natural successor to the jet airliners that had entered service only a few years earlier. Whitcomb, who in 1958 had become head of the transonic aerodynamics branch, developed his own SST design. It was beautiful, he says, but, like all SST proposals, impractical because the supersonic regime could not avoid drag penalties. Around 1962 he abandoned it and cast about for another project. It came to him in the form of the supercritical wing.

There was clearly a need for airfoils suitable for transonic flight—ones that experienced a gradual drag rise rather than a steep one once supersonic flow had appeared. The problem was that there was no approach to designing them comparable to the mathematical methods then available for subsonic airfoils. The transonic situation was many times more complex.

Whitcomb’s first clue to a solution came in the form of unexpected wind tunnel results for an airfoil intended for use on a vertical-takeoff fighter. A section of the airfoil had a flap, with air passages, or slots, between the flap’s leading edge and the wing, and Whitcomb found that the flap was capable of delaying the appearance of the shock wave that was responsible for the transonic drag rise. After studying the slotted section for some time, he concluded that it could not work well when fabricated with reasonable precision. Abandoning the slot, he turned his newly enhanced intuitive grasp of shock wave mechanics to the creation of a shockless singleelement airfoil. His tools were the ones that had served him in the past: the wind tunnel and his creative mind.

The tunnels with which Whitcomb worked had eight-foot test sections lined with thick steel plates and slotted to prevent “choking” at transonic speeds. The roar of their fans, powered by 16,000-horsepower electric motors, could be heard and felt through the building day and night. The first—the “old” HST, or high-speed tunnel—was open to the humid Virginia atmosphere, and in the summer, models became invisible in the test section because of the fog that formed as the flow speed built up and the air pressure inside consequently dropped. The data-gathering equipment was in the chamber surrounding, and open to, the test section, so the researchers worked armed with ear muffs to prevent deafness and oxygen masks to avoid hypoxia. The “new” eight-foot tunnel, which entered service in 1953 after Whitcomb’s area rule work was largely done, had a closed circuit. It recirculated the same dry, fog-free atmosphere, it could be pressurized to increase the density of the working air, and its data gathering space was insulated from the test section.

Characteristically, Whitcomb’s approach to airfoil design was sculptural, intuitive. Beginning with a conventional wing of two-foot chord (distance from leading to trailing edge) equipped with instruments to measure pressures along the chord, he added bulk here with plastic auto body putty and removed it there with a file and sandpaper, looking for a pressure distribution that would delay and weaken the shock that arose at the point where the upper-surface flow decelerated from supersonic to subsonic speed. It was not a simple job; pressures and velocities could not be changed at one place without producing unwanted changes everywhere else. It’s unlikely that anyone but Whitcomb would have thought to undertake it. But he did, working two shifts a day, sleeping at times on a makeshift cot, obsessively completing run after run in the transonic tunnel.

By the late 1960s Whitcomb had pioneered a new class of airfoils. Their shapes were counterintuitive—the leading edge was blunt and thick, in contrast to the knife-like sections usually associated with supersonic flight; the upper surface was so gently curved as to appear almost flat; the lower surface bulged so deeply that the airfoil seemed to be flying upside down; and its trailing edge hooked downward with a cusp so marked that it almost resembled a deflected flap.

As with the Transonic Area Rule, Whitcomb was not alone in his line of investigation. A British researcher, H.H. Pearcey, had designed a class of “peaky” airfoils that achieved a moderate delay in the drag rise and were used on the first generation of jet transports. Other researchers had noted, with puzzlement, bizarre evidence that conventionally cambered airfoils seemed to have lower drag at transonic speeds when operating upside down—that is, with the same relatively flat top and bulging bottom that would become the hallmarks of Whitcomb’s section. As with the Transonic Area Rule, however, it was Whitcomb’s intuitive approach to the physical problem, through sculptural experimentation and wind tunnel verification, that succeeded where paper and pencil had failed.

Nevertheless, Whitcomb agreed with his bosses at Langley, who, while acknowledging the importance of his accomplishment, observed that not every airplane manufacturer in need of an airfoil could be expected to adopt his manual procedure for designing it. There had to be an analytical method—that is, one that enabled transonic sections to be arrived at mathematically. NASA let a substantial contract to the Courant Institute at New York University, where mathematician Paul Garabedian and aerodynamicist Anthony Jameson, in consultation with Whitcomb (one of whose strengths, Jameson says, was a readiness to look at other people’s ideas), eventually developed a practical computational method for designing what Whitcomb termed “supercritical” airfoils—those that were most efficient in the transonic range.

Full-scale test aircraft—in 1971 a Vought F-8 Crusader, and in 1973 a General Dynamics F-111—were equipped by NASA with supercritical wings and flight-tested at the NASA Flight Research Center in California (renamed the Dryden center in 1976). Before the first tests, Whitcomb himself, ever the sculptor, climbed out onto the wing of the F-8 with a hammer to irritably reshape some protruding sheet metal. The experimental findings supported the wind tunnel measurements, and the term “supercritical” became part of every aeronautical engineer’s vocabulary. The supercritical wing won rapid acceptance by industry. NASA conferred upon Whitcomb a $25,000 prize, and he received the 1974 Wright Brothers Memorial Trophy from the National Aeronautic Association.

Unexpectedly, Whitcomb’s supercritical airfoil produced a spinoff for general aviation. Its thick, blunt leading edge allowed it to generate an unusually large amount of lift before stalling, and Whitcomb published a low-speed airfoil, which he called the GA(W)-1—for General Aviation (Whitcomb)—which has been used in several small airplanes.

Whitcomb next turned his attention to the problem of a complete supercritical aircraft, and, three decades before Boeing announced its Sonic Cruiser, he designed a “near-sonic transport” theoretically capable of operating economically at 98 percent of the speed of sound. As with the supercritical wing, Whitcomb developed his design in the wind tunnel with body putty and a file, subtly adjusting its marked area-ruling in order to muffle secondary shocks arising from the intersection of body and wing. But Whitcomb’s nearsonic transport configuration was never to be adopted for a full-scale airplane. There were various reasons. One was the rising cost of fuel in the early 1970s, which led airlines to demand not faster aircraft but more economical ones. But this was the era of the Concorde as well—hardly an economical design—and a more mundane reason may also have played a role: Since its fuselage varied continuously in width, the Whitcomb configuration did not accommodate a regular arrangement of seats and aisles. Or maybe it was just a simple case of “not invented here.”

It was in response to the airlines’ post-oilembargo demand for increased efficiency that Whitcomb produced his third innovation, the one perhaps best known today: the winglet. That some kind of barrier at the tip can improve a wing’s performance had been known for decades, but Whitcomb was apparently the first to realize that such a barrier would be most efficient if it took the form of a supplementary vertical wing. Although experimental winglets reduced fuel consumption by five percent or more, designers were skeptical of the idea, and it was slow to take hold. Today, however, many transport aircraft and business jets have winglets. So do a number of lighter airplanes for which they are not really appropriate and to which they have been added for looks alone. (See “How Things Work,” Aug./Sept. 2001.)

In 1980, Whitcomb, 59, suddenly—and, to many who knew him, surprisingly—retired. His reasons were several. One was mental and emotional exhaustion from unsuccessfully grappling with a project outside his field of transonic aerodynamics. It was a scheme seemingly from the border of science fiction that at once lured and resisted him: to harvest energy from the environment in ways that conventional physics forbade but, he thought, quantum physics just might allow. Another more prosaic reason was a disagreement with management. Headstrong, independent, and confident in his own insights, he no longer cared to work in NASA’s increasingly bureaucratic and compartmentalized organization, and on projects that he believed—the aftermath has borne him out—to have no future. He continued for years afterward to consult with industry. “Basically, I told them what they were doing wrong,” he says. His clients got their money’s worth; Whitcomb “could explain things better than anyone I ever saw,” says former colleague Gerry South. But the work eventually dwindled. “By now,” Whitcomb says, “what I know is old hat.”

At 81, Richard Whitcomb is one of aviation’s grand old men. A brisk, trim, white-haired figure, he takes long walks in Hampton, where he has lived since 1943. He watches his diet; his principal activity these days, he says, is “staying alive.” He likes 19th century classical music, and pictures and sculptures whose forms seem to him to embody deep principles of energy and motion. He lives alone. He never married, but for 25 years kept company with a NASA mathematician, Barbara Durling; she died last year. Several of his more prestigious awards are on display in his small apartment, but he has received, and still receives, too many for his shelves and walls to handle. “I’m at the age,” he ruefully jokes, “where they start to give you those ‘lifetime achievement awards.’ ”

His apartment building is beside a narrow estuary of the Chesapeake Bay. Across the water is the wind tunnel in which he spent his professional life. The tunnel was both a home and a friend to him. Without it, he says, he could never have become what everyone today agrees he is: one of the greatest aeronautical scientists of the 20th century.

Home on the Transonic Range

The speed of air passing over a body increases over bulges and decreases into cavities, and the air pressure varies in inverse relation to the speed. This is the Bernoulli phenomenon, to which wings owe their ability to produce lift.

When an airplane is moving very fast, the flow over some parts of it, in particular the upper surfaces of the wings, accelerates to supersonic speed, even though the airplane itself is flying below the speed of sound. The airplane speed at which local supersonic flow first appears is called the “critical speed” or “critical Mach number.” For wings with conventional subsonic airfoils, it is typically around Mach .75, or about 500 mph. The range between the critical speed and Mach 1.0, the speed of sound, is called the “transonic range.” Problems confronted the first airplanes exploring those speeds. Patches of supersonic flow generated shock waves that could disrupt the subsonic flows in their wake, causing massive turbulence, loss of lift, and an increase in drag to two or three times the subsonic value.

Immediately after World War II, as airplane speeds were entering the transonic range, the nature of transonic flow was not well understood. Tests were conducted with weighted models dropped from airplanes at high altitude, carried on the noses of rockets, or mounted above a bump in the floor of a wind tunnel. But progress was slow until Ray Wright, a researcher at the National Advisory Committee for Aeronautics center at Langley, Virginia,working, like Whitcomb, with filler and file, discovered how to tailor slots in the wind tunnel’s walls so as to yield reliable results up to and beyond the speed of sound.

When transonic phenomena could be studied under controlled conditions in a wind tunnel, they yielded their secrets to Whitcomb and others. New ways were found to reduce or eliminate shock waves. Whitcomb coined the term “supercritical” to describe airfoils designed so that the drag rise occurs well past the critical Mach number. Supercritical wings are now used on all new airliners and business jets, enabling some of them to cruise economically at speeds as high as Mach .92.