The Mojave Launch Lab

A community of alternative rocketeers who may one day dominate the space biz.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/The_Mojave_Launch_Lab_1_FLASH.jpg)

Elsewhere, Roton might have been discreetly withdrawn from public view long ago. But at the Mojave, California Air and Space Port, the towering, cone-shaped rocket-helicopter hybrid is permanently displayed at the entrance to the administration building, right where the facility’s general manager, Stuart Witt, wants it. A late 1990s dsesign for single-stage-to-orbit spaceflight, Roton started with an Atmospheric Test Vehicle, which got off the ground three times, never higher than 75 feet. But Witt says it ushered in a new era of thinking: “That you didn’t have to be Boeing or Aerojet. That the small guy was free to dream big and take big risks and maybe create a breakthrough at a place called Mojave.”

Speaking with Jeff Greason, CEO of the Mojave-based spaceflight venture XCOR Aerospace, I stammer for a word more diplomatic than “failure” to describe Roton, which he worked on over a decade ago. “Just go ahead and say it,” Greason laughs.

In the 1970s, Witt’s predecessor, Dan Sabovich, envisioned Mojave as the civilian counterpart to aerospace test facilities at nearby Edwards Air Force Base. By 1982, designer Burt Rutan had turned his revolutionary kitplane business at Mojave into Scaled Composites, creator of the round-the-world Voyager and Beechcraft’s all-composite Starship. Not many years later, Witt says, Rutan began thinking outside the atmosphere.

Witt is a Top Gun grad and former Navy F-14 aviator who exudes a fighter pilot’s cool and edge, even behind a desk. As its director, he is the spaceport’s driving force and philosopher-in-residence. From his expansive office windows, with views of outstretched runways and desert mountains smoldering in the distance, Witt points up at airspace. “It’s a drawing card of epic proportions,” he tells me. “Think about what drew Wilbur and Orville to Kitty Hawk. Freedom from encroachment of the press, freedom from industrial espionage, and a steady breeze. You could easily say, ‘That’s exactly what’s at Mojave too.’ ”

Witt works, lectures, and lobbies to keep it that way. He’s a big-picture guy, but big government programs aren’t part of it. He views NASA “not as bad people” but as an agency strangled by complexity, both organizationally and with vehicles like the shuttle: “Think how many miracles had to occur to get that thing into space.” Witt maintains that routine escape from the atmosphere can come only via private-sector efforts, noting that 50 years of government-funded launches have put only about 500 people in space. “It’s kind of an embarrassment,” he says.

Mojave’s diverse and often unconventional tenants present challenges a county airport manager doesn’t encounter: From maverick Burt Rutan, working wizardry behind the big doors at Scaled Composites, to the marketers of “premium micro-gravity” and exotic propellant brewers occupying metal hangars, some without air conditioning, in the middle of a desert. Almost daily, one of them is in Witt’s office. “Sometimes it’s a pleasant discussion,” he says. “Sometimes it’s fists pounding on my desk. Sometimes it’s ‘You gotta get these regulators off my butt.’ ” Witt’s official function—and personal mission—is to facilitate the free thinking and farsighted, “then get out of their way.”

Pre-dawn at the Mojave McDonald’s, photographer Chad Slattery and I rendezvous with a pair of Air Force officers. Incognito in jeans and T-shirts, Lieutenant Colonel Ladonna Davis of the Air Force Research Laboratory and Captain Jeremy Selstrom from Edwards Air Force Base will escort us down dirt roads to the Friends of Amateur Rocketry launch site.

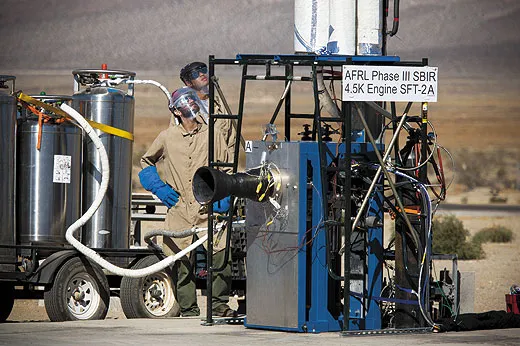

At a dry lakebed, a Small Business Innovative Research contract from the Department of Defense’s Operationally Responsive Space Program Office draws a consortium of students from California State University at Long Beach. With them are representatives from a lean, mean spaceflight contractor and several Friends of Amateur Rocketry mentors. Overnight they’ve prepped a 4,500-pound-thrust rocket engine fueled by ethanol and liquid oxygen for a day of static tests. Garvey Spacecraft Corporation is the contractor developing a vehicle to economically loft tiny nano-satellites into low Earth orbit. Cal State students receive hands-on experience; John Garvey gets the prospect of selling the Responsive Space Office 10 rockets a year. “It’s a very professional group,” Selstrom says. “Believe me, if you tried to do this at the Air Force Research Lab, you’d get maybe two tests a day, if you’re lucky. It’s a big facility and they’ve got much larger fuel tanks and systems to deal with.” At Friends of Amateur Rocketry, the purge/refuel turnaround between tests can be accomplished in only an hour.

Eric Besnard, a Cal State Long Beach professor of mechanical and aerospace engineering, assures in a faint French accent, “If it fails, it should only be a burn-through, not a catastrophic failure.” Mounted horizontally on a test stand at the Friends of Amateur Rocketry site, the Cal State Long Beach engine vents vapor in the morning air. Designed and constructed by Besnard’s students, it will be tested in 20-second burns, building toward a total of 120 to 150 seconds, necessary to launch an orbital first stage. Each second accumulated brings the project a little closer to the approval to launch at a NASA facility like Wallops Island in Virginia.

For students, it’s out of the classroom and into real-world rocketry. “There aren’t many 22-year-olds who’ve loaded LOX [liquid oxygen] and ethanol into liquid rockets,” says Garvey. New guys get assigned to fuel loading: “That’s kind of the cool, macho thing to do, you know. They can say, ‘Hey, I’m working with LOX.’ ” The experience separates the more theoretical-minded from those having “the field test mentality,” as he calls it. Things aren’t clean, it’s not pretty, “and you may be working late.” A student using coarse language in range of videocams recording the test catches his notice. “Hey, no seven-letter words,” he barks.

Garvey already has one minute on the engine; he hopes to double that today. “By getting 60 seconds of burn, even in three chunks, we’ll know the chamber is pretty robust.” There’s a trade-off between burn time and weight: Each burn erodes the combustion chamber more. “If you build enough material into it, it will last longer. But as you add more material, it also gets heavier.” And requires more fuel. “So we’ve got to find the right mix.”

The scent of ethanol from the Cal State Long Beach engine drifts over the site. Kevin Baxter, Friends of Amateur Rocketry president, revels in it. “We’re five miles from the nearest human being,” he says. “It’s a magical place.” It’s also an amateur facility unlike most: Surrounding a Quonset structure are horizontal and vertical test stands, two launch towers, propellant storage vaults, and an underground blockhouse with electrical and network connections—all built by volunteers, usually at launch-and-work events. “People come watch a rocket fire,” Baxter says, “then a cement truck shows up.”

FAR’s mission statement promotes rocketry education, for everyone from Boy Scouts to university students. Its mentoring process links amateurs with space industry pros, many of whom launch here recreationally. “Think of all the frustrated engineers shuffling papers in the big aerospace corporations,” Baxter says. Mark Holthaus, an FAR founder, is an example. At Boeing in Huntington Beach, he engineers exotic projects like the X-51A hypersonic engine. Meanwhile he’s got an amateur rocket “in pieces on the living room floor” and spends weekends mentoring students at FAR.

FAR holds high-explosives manufacturing permits from the Bureau of Alcohol, Tobacco, Firearms, and Explosives, as well as Federal Aviation Administration clearance for weekend launches up to 50,000 feet. Solid-propellant amateur rockets have flirted with maximum permissible altitude: a dirt-biker found a university’s 12-foot vehicle, three months after launch, miles from the FAR site. (The higher the altitude, the more the downrange drift, and, ultimately, the more difficult to find.)

Down in the blockhouse, Garvey Spacecraft test conductor Chris Bostwick (a Cal State Long Beach grad) monitors engine status on computer screens and executes the test sequence. John Garvey mans the red kill switch to shut down the engine if a computer locks up. Final propellant temperatures and pressures are logged. A voice on the loudspeakers orders everyone behind cinder-block observation bunkers, earplugs in. Moments later, terminal countdown squawks over the speakers.

The shock wave from 4,500 pounds of thrust rocks the earth. A pale blue exhaust plume lunges more than 20 feet, and an enormous cloud of dust roils across the desert. Ethanol and liquid oxygen rage; seconds click by. After 20, the computer shuts down the engine.

Applause rises from bunkers. “We’re good,” Garvey says, emerging from the blockhouse.

At Masten Space Systems, I’m up close with suborbital prototype Xombie, star of YouTube videos and recipient of the 2009 $1 million NASA/Northrop Grumman Lunar Lander X-prize.

Xombie is even hotter in person: A reusable vertical-takeoff/vertical-landing vehicle, about the height and girth of an industrial water heater, with four landing struts and a single liquid oxygen/isopropyl alcohol engine. Xombie is the test horse for big sister Xaero, scheduled to offer commercial lifts into a high-quality microgravity environment (like that on an orbiting space shuttle, as opposed to high-altitude balloons or sounding rockets) sometime this year.

Dave Masten designed networks for IT icons like Cisco Systems and Ameritech. But before that, “I was a kid shooting off Estes model rockets,” he says. He advanced to high-powered rocketry—“Estes for adults with adult budgets”—then went above and beyond amateur status. At his first startup, in Santa Clara, certain “loud noises” drew complaints from neighbors. “In 2006, the golden handcuffs were freed from my previous ventures in Silicon Valley and I was able to move the company,” he says. “I found this place, where they actually like the idea of rocket tests. It was easy to fit into Mojave.”

Masten aims to market a low-cost microgravity environment for educational and scientific payloads. Xaero and Xogdor (still in development) promise access above 100,000 feet, without the drawbacks such as survivable ejection from expendable sounding rockets and rough parachute landings. On reusable vehicles like Xombie, the payload stays with the rocket, which soft-lands back on the pad it took off from. “We’ve tried to make them as autonomous as possible,” Masten says. “Computers are much better pilots than humans are.” Guided by GPS and inertial measurement units, vehicles reach Mach 2 before engine shutdown, then coast to their suborbital apogee, or high point. During freefall reentry, engine relight and deceleration occur a dramatic few hundred feet above the launch/landing pad. Xombie is the world’s first vertical-takeoff/vertical-landing vehicle to relight an engine in flight.

Payloads bask in high-quality microgravity up to four minutes. Xaero will offer less gravity than what zero-G aircraft provide, while the higher-reaching Xogdor should deliver microgravity as low as that experienced on the International Space Station.

With a small space startup’s focus on the bottom line, Masten keeps components as third-party as possible. Xombie’s onboard computer is an industrial module common in automotive applications. But I’m unprepared for the off-the-shelf WiFi base station—pretty much what I’ve got at home—that downlinks telemetry from the rocket. During his IT days, Masten engineered a project that beamed WiFi across San Francisco Bay. “You’ll replace that with something more permanent for suborbital flights?” I ask. Masten shakes his head and grins: “We’re gonna try to make it work all the way up. I am not kidding.”

When Apollo astronauts lifted off the moon, they left behind a lot of things besides footprints. Toxic hydrazine fuel contamination was one. Not a problem—nobody was returning soon. But for repeat visits to a lunar or Mars base, Greg Mungas says, “Having a non-toxic propellant will be a big deal.”

A former Jet Propulsion Laboratory engineer, Mungas formed Firestar Technologies and moved to Mojave to make rocket science greener. “We started playing around with the idea of blending fuels with nitrous oxide for deep-space applications,” he says. A research contract from NASA’s Mars Advanced Technology Program resulted in NOFBX, Firestar’s patented mono-propellant.

“Nitrous oxide just decomposes into oxygen-rich air,” Mungas says. And monopropellants don’t require separate tanks of liquid oxygen. Mungas likens the propellant to “the propane bottle you take on camping trips,” something that fuels the camp stove, lights lanterns, and runs a generator. NOFBX from the tank that fuels a spacecraft’s rockets could also generate onboard electricity and drive turbine-powered equipment on a planet’s surface.

For a contract with the Defense Advanced Research Projects Agency, Firestar developed a NOFBX-fueled piston engine for high-altitude, long-endurance drones. “It’s the unmanned equivalent of the U-2 spyplane,” Mungas says. Piston engines, powering everything from generators to small aircraft, have been modified in-house to run at altitudes with almost no oxygen.

Firestar engineers Ken Doyle and Greg Peters show me around the spaceport test site, north of the runways. “Big bangs happen here all the time,” Doyle says. “You never know whether it’s something at the [Soledad Mountain] gold mine over there or a test in progress.” Firestar’s site includes a 40-foot drop tower to shock-test propellants and a burn pit to cook them. A static stand for 10,000-pound-thrust engines throws fire out toward the scrub. “Depending on the amount of stuff that might explode,” Doyle says, the control room—an air-conditioned, computer-equipped, microwave-linked, steel shipping container—can be transported to safe distances.

Not everything else can. “My cousin’s got an old Firebird up on blocks,” says Greg Peters. “I tell him, ‘Guess what I’ve got up on blocks?’ It’s an 80,000-pound vacuum chamber made by General Dynamics in the 1960s to simulate deep space for satellites.” Mungas, who rescued the behemoth from a San Diego boatyard, is renovating the rare asset. Says Peters: “We can put sand and rocks inside, pump it down to Mars pressure, backfill it with CO2, and essentially create the Mars environment. Right here in Mojave.”

It’s “spaceflight participants,” not “space tourists.” XCOR’s Mike Massee is talking about booking suborbital spins in the Lynx Mk. II rocketplane. Compared to Virgin Galactic’s six-passenger SpaceShipTwo, Lynx is the scrappy two-seater down the block. Last September it completed supersonic wind tunnel tests at NASA’s Marshall Space Flight Center in Alabama. Co-founded by Jeff Greason and several Rotary Rocket alums, XCOR targeted human “participation” from the get-go. The company’s EZ-Rocket is a Rutan Long-EZ homebuilt aircraft modified with twin rockets powered by isopropyl alcohol and liquid oxygen. “We made this just to prove we could make a rocket-powered airplane and fly it,” Massee says. And finding a pilot was EZ—Dick Rutan, Burt’s brother, has more hours in the Long-EZ than anyone. “That’s another cool thing about Mojave,” he says. “You walk a few doors down to your neighbor and say, ‘Hey, wanna fly the world’s first rocket-powered Long-EZ?’ ”

A few feet from EZ-Rocket stands a full-size Lynx mock-up, on which cockpit ergonomics are tweaked. The delta-wing aircraft, fueled by kerosene and liquid oxygen, will take off and land horizontally. Between those conventional events: 37 miles straight up at Mach 2. An interlude of weightlessness—with panoramic overhead windows providing killer inverted Earth views—then a 4-G pullout and a circling, dead-stick reentry. Thank you for flying XCOR.

Jeff Greason came to Mojave via Intel. Why are so many space entrepreneurs Silicon Valley expats? “We’re all people who grew up in an era when the promise of the Apollo program was that it would keep going,” he says. But computers, not NASA careers, were the magnet for tech-minded whiz kids. “Once we got free to do what we really wanted to do, some of us looked back at the space industry and started asking, ‘Why is this not progressing?’

“The culture in the traditional U.S. aerospace industry looks a lot like the culture of other industries, circa 1960,” Greason says—large, specialized, and compartmentalized. Even private launch ventures like SpaceX dwarf XCOR. Expendable vehicles require a large organization, he explains, “but reusable vehicles like the Lynx can’t have one or they aren’t economically successful.” He’s not competing with big NASA launch contractors like SpaceX—he’s applauding their efforts: “I would love to see that business recaptured by American companies.”

At current projections, a Lynx ticket will cost $95,000—half the price of Virgin Galactic’s. Based on industry predictions of commercial spaceflight demand, “hundreds of people a year will buy a ticket into space at any price,” Greason says. He points out the burgeoning market for opportunities to climb Mt. Everest at prices up to $100,000, where some percentage of customers die every year “and 100 percent are absolutely miserable. There are roller coasters more physically stressful than this,” he says. “And besides, it’s space.”

Tourists or participants, Greason believes ticket-holders won’t be joyriders. “Most will be doing it because they have the same sense I had when I started the company: that space is important, that it’s part of the future, and they want to be a part of the early days of it.”

At the Friends of Amateur Rocketry test site, tanks are purged and the engine is refueled. An igniter fails; then a regulator that controls external helium tanks pressurizing the propellants falters. In the blockhouse, Eric Besnard troubleshoots with Garvey as repressurizations are attempted. A Friends of Amateur Rocketry mentor out at the test stand settles it: “The regulator is done for.” Not a deal-breaker, but subsequent firings must revert to “blow-down” mode without external helium pressure, relying solely on helium pumped into the smaller internal propellant tanks and limiting duration. The next burn lasts just 15 seconds, another only 13. Later, as we roll away from the site in a cloud of dust, the Garvey-Cal State Long Beach team is still reaching for the critical 60.

Though state incentives lured Virgin Galactic and SpaceShipTwo from California to a base at New Mexico’s Spaceport America, Richard Branson says Mojave reigns as the R&D gateway: “It will become the center of experimentation for the new space community as it matures over the next decade.” Stuart Witt believes that in a safe society, risk-taking is an endangered thing. “But it’s alive in these hangars,” he says. “We need to pick winners and losers and get on with it.” He leans back and looks out again at Mojave’s surface-to-infinity blue.

It’s after dark when John Garvey sends me a text message from his Blackberry: “Done. We are out of fuel. 77 seconds.”

Frequent contributor Stephen Joiner writes about aerospace from his home in southern California. His last feature, about aircraft repossessions, appeared in the April/May 2010 issue.

Contributing editor and photographer Chad Slattery specializes in aerospace subjects. He is based in Los Angeles.