The O Prize

Will Rocketplane launch spacecraft from Oklahoma?

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/oprize_388-nov07.jpg)

WHEN THE ANSARI X-PRIZE was awarded in 2004 to Burt Rutan’s Scaled Composites for making the first privately funded manned trips to space, the other teams that had been vying for the $10 million prize money, though no doubt disappointed, kept plugging away at their designs for commercial spacecraft. Some, Rocketplane Global among them, are now racing to be the first to offer suborbital tourist flights; I chronicle these efforts in my recent book Rocketeers.

Since the book was printed, Rocketplane hit some turbulence on the way toward launching Rocketplane XP, its space tourism vehicle. In August 2006, the company won a contract through NASA’s new Commercial Orbital Transportation Services program to develop orbital cargo ships for servicing the International Space Station. Because the NASA money is earmarked strictly for orbital ships, the company began channeling its engineering resources away from the suborbital Rocketplane XP and into an orbital spaceship under development by Rocketplane’s newly acquired Kistler Aerospace.

The decision delayed launch of the suborbital vehicle by at least a year; the first flight is now planned for 2009 instead of 2008, and only if the company can raise additional funds. Among the casualties of the work slowdown: chief engineer David Urie, who was laid off last May. The company also says to expect changes in Rocketplane XP. “It will still have the same bizjet look,” says Rocketplane’s George French III, and the mission profile will be the same. As this issue of Air & Space/Smithsonian went to press, the company had not released specific information about the modifications.

In the meantime, the contest for the suborbital tourism market has a new entrant. In June, EADS Astrium, a division of the formidable European Aeronautic Defence and Space Company, announced its design for a tourist spaceship. EADS Astrium’s vehicle, which has yet to receive a name, will send four passengers and a pilot into space, using twin jet engines to climb to 39,000 feet before firing a rocket engine fueled by methane and liquid oxygen. The design bears more than a passing resemblance to Rocketplane XP. Explains Astrium chief technical officer Robert Lainé: “A self-propelled plane is going to be the best for the operator because then they can fly from [any] airport,” with no special launch infrastructure required.

The following excerpt from the book Rocketeers: How a Visionary Band of Business Leaders, Engineers, and Pilots is Boldy Privatizing Space, by Michael Belfiore, is reprinted by permission of Smithsonian Books/Collins, an imprint of HarperCollins publishers.

In April 2005, I had dinner with Rocketplane business development manager Chuck Lauer at an Oklahoma City sushi bar, along with the company’s Japanese business representative and Reda Anderson, the first person to pay for a ride on the company’s Rocketplane XP.

Anderson stabbed a finger at Lauer and said, “You have one year to find me a man.”

“Me?” laughed Lauer. “You have to do that.”

“I can’t do that,” said Anderson. “I’ve tried.”

Lauer had just finished describing the marketing scheme he and our other tablemate, Ms. Misuzu Onuki, had hatched: Rocketplane would host the first wedding in space.

Rocketplane XP would be a suborbital vehicle, imparting only four minutes of weightlessness after its rocket engine cut off and it coasted out of the atmosphere at supersonic speed. The bride and groom would have to work fast, and in cramped quarters. The ship would have four seats. The pilot would have his hands full flying it. The bride and groom would ride in the back. That left the right front seat for a priest, rabbi, or justice of the peace. Nevertheless, Onuki had already been collaborating with a fashion designer in Japan on a dress whose white trusses would rise in graceful undulating ripples below the bride’s seatbelts when weightless.

Much as Anderson liked the idea, she lacked a crucial ingredient: a groom.

At 66, she doesn’t look anywhere near her age. Slim and athletic, she smiles easily and laughs often, but steel in her eye hints at the no-holds-barred deal-making that earned her a minor fortune in California real estate.

After watching Scaled Composites’ SpaceShipOne rocket into space on June 21, 2004, Anderson couldn’t resist the idea of going herself. Only days after that company won the X-Prize, Anderson met Lauer at a space conference, and after Lauer gave her the Rocketplane pitch, she asked for a business card. She wrote “Number one signed customer” on the back of it, signed it, wrapped a dollar bill around it, and handed it back. Lauer later explained, “The dollar made it a genuine contract.” Lauer had once been a real estate wheeler-dealer himself; the two spoke the same language.

Lauer had always thought that providing tourist flights to space made good business sense, even when it was unfashionable to think so. Back in mid-1995, when he’d co-founded Rocketplane, the prevailing wisdom among rocketeers was that the real money to be made was in satellite launchers. No one would take the company seriously, his board told him, if one of its principals went around talking about sending people into space for fun. Then, in the late 1990s, the bottom dropped out of the satellite launch market, and in 2001, Dennis Tito became the first passenger to buy a ride into space, shelling out $20 million for a trip on a Soyuz spacecraft. Clearly, there was a market for space tourism.

ONE DAY IN APRIL 2006 found Anderson peering down the throat of a sawed-off Learjet 25 fuselage at Rocketplane’s workshop at the airport in Guthrie, Oklahoma. Structural engineer Derrick Seys pointed to guidelines marked on the white hull like those drawn on a patient’s skin before surgery. He explained how his team would splice in part of another salvaged fuselage to lengthen the original by a good 20 inches—space needed for kerosene and liquid oxygen tanks that would power a 36,000-pound-thrust rocket engine in the craft’s tail.

According to company engineer Bob Seto, starting with an existing fuselage made more sense than designing one from scratch. “There’s a big cost to designing the details of a fuselage,” he said. “Purchasing the fuselage reduced a lot of that risk and development effort. We don’t have to spend a large amount of time starting from a blank sheet of paper.” Bill Lear’s business jet can take 3-plus Gs without breaking up, and has an operational ceiling around 50,000 feet—above 90 percent of the atmosphere.

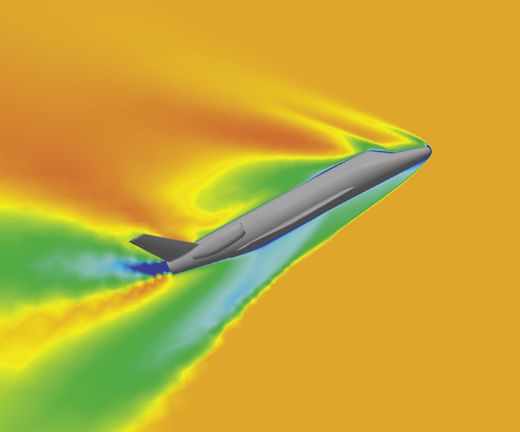

Rocketplane would replace the Learjet’s horizontal stabilizers with a V-tail that would better enable the plane’s nose to pitch up coming off the runway with a heavy load of fuel. The Learjet’s wings would be replaced by a new delta-shaped assembly that was optimized for supersonic flight and, like the original wings, would hold jet fuel. The wing assembly and tail would also give the ship the extra structural hardiness it needed for the 4-G spaceflight.

By the time workers finished transforming the gutted shell into the Rocketplane XP, there wouldn’t be much left of the Learjet: just that fuselage, or rather two fuselages, and the Learjet 25’s standard pair of General Electric CJ610 jet engines. The engines would power the spaceship to a launch altitude of 25,000 feet. There, the pilot would shut down the jets and light the rocket engine for a 70-second boost to space and a maximum speed of three and a half times the speed of sound. After the rocket engine shut down, Anderson would get four minutes of weightlessness, a view extending as far south as the Gulf of Mexico and west to the Rocky Mountains, and, with any luck, her wedding-day kiss.

A personal display for each passenger would let everyone toggle through views piped in from seven cameras around the craft. For good measure, the pilot would use the ship’s reaction-control system (RCS) to roll the craft so all the windows got a good look at Earth.

The Rocketplane XP pilot would navigate the changes in pressure and speed experienced during reentry by using computerized flight controls. And the engineers would give Rocketplane XP at least one advantage over SpaceShipOne. As the ship left and then reentered the atmosphere, the XP’s computers would blend RCS control with inputs from standard airplane control surfaces, providing seamless control at all phases of the flight. The XP’s computers would fly the ship from boost to reentry, with the pilot taking over only in an emergency and for landings. The pilot would restart the jet engines at 20,000 feet for a powered landing. Total flight time: 60 minutes.

The idea had been hatched by Mitchell Burnside Clapp, an aerospace engineer and former test pilot instructor for the Air Force, as a way to get himself to space. While still in the Air Force, Burnside Clapp decided to try to resurrect a perennial Air Force dream: building a manned spaceship the armed forces could call their own. His initial idea was for a single-seat rocketplane, one that could rocket into orbit to launch small satellites.

Burnside Clapp left the Air Force to pursue a commercial version of the ship, forming Pioneer Rocketplane in 1996 with Chuck Lauer and aerospace engineer Robert Zubrin (best known for the concept of manned expeditions to Mars making their own return fuel from elements of the Martian atmosphere). Pioneer Rocketplane set its sights on the X-Prize, but it was chronically short of funds. Zubrin left the company in 1998.

In 2003, the company got a fresh cash infusion from a new president, Wisconsin outdoor advertising businessman and space enthusiast George French, who had been an early investor. As 2003 drew to a close, French, Lauer, and Burnside Clapp saw within their reach a cash award that was worth even more than the X-Prize. They called it the O-Prize.

The state of Oklahoma needed good jobs; young graduates who couldn’t find work in the state were leaving to seek work elsewhere. The solution Oklahoma came up with: provide tax credits to technology companies. In exchange, the company would have to be headquartered in Oklahoma, have at least $10 million already invested in it, and demonstrate that it really would produce new jobs for the state.

The Oklahoma Space Industry Tax Incentive was worth $18 million in tax credits. The beauty of the credits was that they were transferrable—the company that got them could sell them for cash.

The O-Prize had to be won before 2004. Rocketplane beat out its competitors to win the prize in the final hour: at 4:42 p.m. on December 31, 2003. French then sold the credits for $13 million, and at last the Rocketplane XP had wings.

Early in 2004, French brought in aerospace engineer David Urie to lead the Rocketplane design team. Not long afterward, Burnside Clapp quit the company. “ ‘Citing creative differences’ is the standard Hollywood way to say that, right?” he said to me. He declined to elaborate except to say that he was skeptical of the idea that flying tourists in space was a viable business operation for something as cash-intensive as building and flying a spaceship.

French would have been hard-pressed to come up with a better engineering chief than David Urie. Urie came to Rocketplane after 30 years’ experience as an engineer and manager at Lockheed Martin’s famed Skunk Works. During his 50 years at aerospace companies like Boeing and Douglas Missiles, he worked on 35 types of aircraft, from long-haul bombers to missiles.

Urie couldn’t resist coming out of retirement to work on one last bold aerospace engineering project. The chance to fly into the market under the radars of monolithic aerospace companies like Urie’s previous employer was just too good to pass up.

Once settled at Rocketplane’s new headquarters, a single-story building at Oklahoma City’s Will Rogers Airport, Urie set about hiring a team of engineers composed of equal parts seasoned veterans and young engineers right out of school. One of Urie’s prime hires was engineer Bob Seto, who took over the day-to-day operation of building Rocketplane XP. Talking to him made the whole enterprise sound almost reasonable to me.

Seto explained that at a maximum velocity of three to four times the speed of sound, Rocketplane XP wouldn’t experience anywhere near the heating from atmospheric friction that the space shuttle, traveling at 25 times the speed of sound, encounters returning from orbit. Nevertheless, reentry heat would pose a problem for an ordinary Learjet’s aluminum structure. Aluminum, used for airframes because of its light weight, melts at a lower temperature than a heavier metal like steel.

So Rocketplane’s engineers and machinists would replace the areas subjected to the greatest heat—the engine inlets, the nose, and the leading edges of the delta wing—with steel or titanium. The rest of the ship would get a coating of a heat-dissipating paint that had been developed at NASA for next-generation spaceships and that had then been released for commercial use. Even though the bulk of the ship would still be of lightweight aluminum, all those modifications, plus the rocket engine and its fuel, added up to a much heftier craft. At takeoff, Rocketplane XP would top out at 19,500 pounds, compared with the unmodified Learjet 25’s 15,000 pounds. The spaceship would need a hell of a long runway to get airborne. Fortunately, the state of Oklahoma had one.

Burns Flat, Oklahoma, is 80 miles from Will Rogers Airport. Bob Seto flew me there, along with Reda Anderson and Misuzu Onuki, in his Cessna 182. He banked on approach so that we could get the best view of the 13,503-foot runway at Burns Flat’s former Strategic Air Command base. It had been built during the cold war for heavily laden B-52 bombers ready to scramble at a moment’s notice to rain nuclear death on the Soviet Union. Seto remarked that he could take off sideways on it. The place was all but deserted. These days the only traffic the place saw was Air Force pilots practicing takeoffs and landings.

In June 2006, the Federal Aviation Administration certified the place as a commercial spaceport, and it officially became known as the Oklahoma Spaceport. This is where Rocketplane chief pilot John “Bone” Herrington will fly from and land if the spacecraft becomes operational.

Herrington had left the NASA astronaut corps early and taken a pay cut to join Rocketplane. He’d flown in space once, on the last space shuttle mission before the shuttle Columbia disintegrated in 2003. He knew he’d likely have a long wait before his next ride on the shuttle, and he just could not pass up a chance to be part of what he thought would be a historic event—the first suborbital flight to carry paying passengers into space.

Anderson grilled Herrington about the Rocketplane XP’s flight profile, about every aspect of the experience of flying in space, about all the potential dangers. And about whether she’d get a good view out the window. “I’m not wild about getting out of the seat and floating around,” Anderson told the pilot. “I’m more interested in the view.” Fortunately, there just wasn’t time to get up and float around and get used to the sensations of weightlessness and take in the sights. The cramped interior of the Rocketplane XP would prevent much floating anyway.

But would Rocketplane XP even get off the ground? Dan Erwin, associate professor of aeronautics at the University of Southern California, thought it had an excellent chance. “The performance numbers given by the company are reasonable, based on their estimate for vehicle mass at launch,” he told me. The team’s greatest challenge would be the ship’s rocket engine.

The AR-36, built by Polaris Propulsion, will run on kerosene and liquid oxygen and deliver 36,000 pounds of thrust. Its regeneratively cooled design (in which kerosene circulates along the combustion chamber’s outer wall before flowing inside to be burned) would allow the engine to be fired many times without much maintenance, just like a jet engine. This design had an advantage over rocket engines with ablative coatings, which char and flake away to take heat with them; ablatives have to be replaced after every firing of the engines.

ROCKETPLANE AND RICHARD BRANSON’S Virgin Galactic, which is buying space tourism craft from Scaled Composites, seem to be vying for the honor of flying the first suborbital space passengers. But theirs are by no means the only ventures gearing up for suborbital flights. Scaled Composites’ neighbor at the Mojave Airport, XCOR Aerospace, has been working on a two-seat rocketplane design that, like Rocketplane XP, would launch under its own power from a runway but without the encumbrance of jet engines; Xerus would be rocket-powered all the way.

And, working in secret, Amazon.com founder and CEO Jeff Bezos has built a self-funded company, Blue Origin, to produce a suborbital tourist spaceship called New Shepard (after Alan B., America’s first astronaut). New Shepard would take off, send three passengers on 10-minute flights out of the atmosphere, return, and land on its tail. According to Environmental Protection Agency papers he has filed, Bezos plans to launch tourists to space by 2010.

With all this competition, it seems possible that within the next decade or two, suborbital passenger service to space could drop to the cost of an ordinarily expensive vacation—a Caribbean cruise, say. But not all of those passengers would be space tourists. In fact, most of them wouldn’t be. “We think that the future for suborbital is really in point to point, both for people and for fast cargo,” said Rocketplane’s Chuck Lauer.

In other words, the biggest market would be for intercontinental travel at rocket speed.