We Built the Saturn V

Memories of a giant-in-progress.

:focal(1638x2756:1639x2757)/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/08/62/0862a808-d3dc-446f-96e4-f950e7496571/09d_on2017_opener_saturnv3s71-17620_orig_live.jpg)

The “V” stood for the five giant F-1 rocket engines—still the most powerful ever built—clustered at the bottom of the Saturn V’s first stage. At one point a four-engine version, the Saturn IV, had been considered, but in the complicated tradeoffs that led to the final design of NASA’s moon rocket, the “V” variant won out.

What became the Saturn grew out of a U.S. military requirement in the late 1950s for a booster big enough to launch large satellites. Wernher von Braun, who had dreamed as a young engineer in Germany of a rocket capable of reaching the moon, was enlisted with his U.S. Army (later NASA) team in Huntsville, Alabama, to lead the effort. When, in 1961, President John Kennedy announced his plan to land an American on the lunar surface by the end of the decade, von Braun got his original wish, and a vast army of engineers, technicians, builders, and bookkeepers went to work to realize the dream.

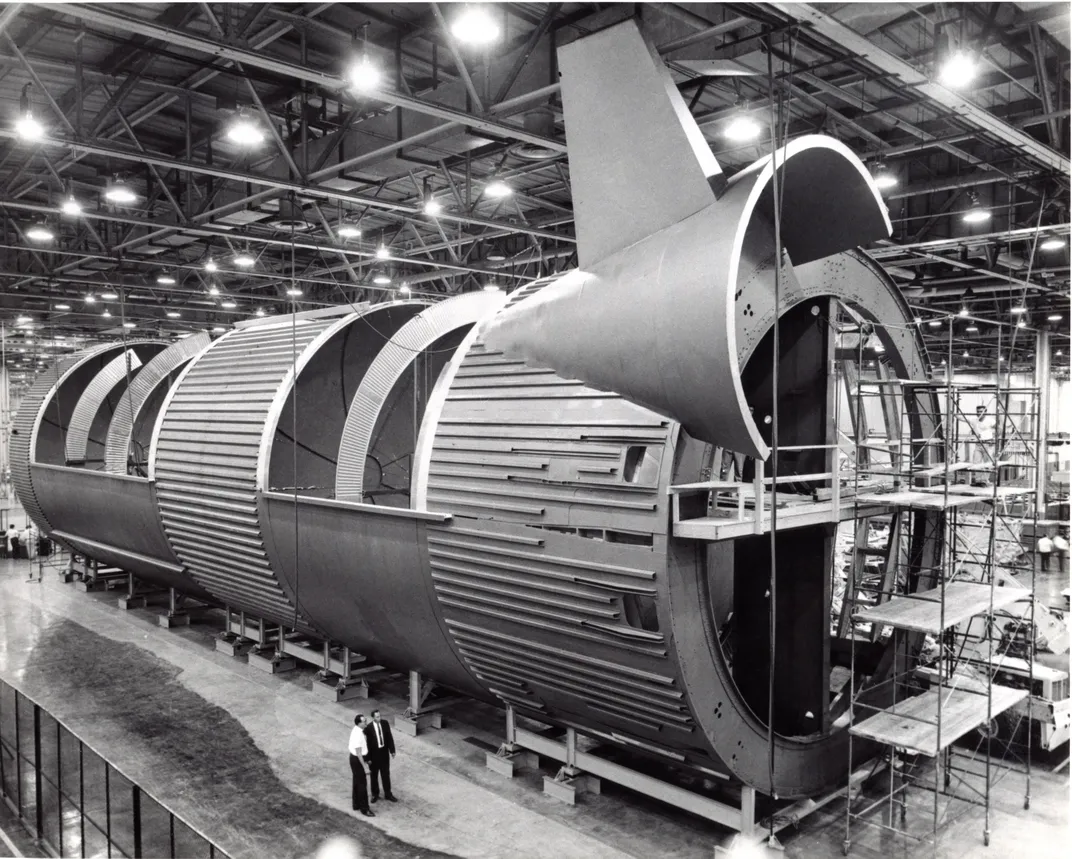

The rocket’s three stages were built and tested by a cadre of private contractors and subcontractors at facilities stretching from California to Alabama. When the pieces were ready, they traveled by barge and custom-made aircraft to Cape Kennedy in Florida, for assembly in what is still the largest single-story building on Earth.

Thirteen Saturn Vs rolled out of that building on a massive “crawler” to their launch pads. At more than $100 million each (equivalent to $750 million today), they departed Earth, then fell in pieces into the ocean.

What they accomplished, sending Americans farther into space than ever before or since, is still one of the nation’s proudest achievements. Perhaps the most impressive thing about the Saturn V was that the first one ever flown—50 years ago this November and scarcely five years after Kennedy’s edict—worked perfectly. And not one failed.

Many thousands of men and women toiled to bring the moon rocket into existence, often putting their personal lives aside and losing untold hours of sleep in the effort. Here, in excerpts from oral histories they recorded, books they wrote, and interviews with Air & Space, a few of them share their experiences working on one of humankind’s greatest machines. Some of the excerpts have been edited for clarity.

A Staggering Challenge

GLYNN LUNNEY, Apollo Flight Director

When I first heard President Kennedy’s [September 1962 “We choose to go to the moon”] speech at Rice University, I was overwhelmed at the magnitude of it. I mean, we were struggling with Mercury spacecraft that weighed 2,000 or 2,500 pounds. [Now] we were talking about spacecraft that would be 10 or 20 times bigger. For me it was just an overwhelming thought that we could actually go and land on the moon and bring somebody back….

The boldness of the decision-making and the challenge that it presented to the country, and to the technical community, was just staggering to me. But we were so busy that it was “Well, okay, I guess we’re going to do that. So let’s get on.”

28 Years Old

LEE SOLID, Rocketdyne

I was the senior executive for the [Rocketdyne] company during those years, with a staff of engineers, technicians, quality [control] folks, and all of the support functions, logistics, and so forth. Rocketdyne provided 33 of the engines [on the Saturn V]. Really the only engine we didn’t have was the descent engine on the lunar module. We had engines on every other stage.

And I was a relatively young guy. When I started working on Saturn, I was 28. We were a relatively young workforce, no doubt about it. On a project of that magnitude, the demand was for engineers, and the schools were putting them out, and this is what they were coming to.

I’d been involved in the Atlas [rocket] program, and for a while there, about every other one we were launching, we blew up. So it was kind of a gutsy thing to put a human being on this relatively unproven [Saturn]. If an Atlas failed, and range safety had to destroy it over land or even just over the beach, we went out and picked up the hardware and laid it out on the floor of a hangar and figured out what happened. If you could figure it out—and in most cases we could—why, you fixed the problem and went and launched another one.

You couldn’t really do that with the Saturn, just because of the massiveness. That Saturn 1C stage, with those five F-1 engines, is a massive piece of hardware. If that sucker was going to blow, it was not only going to take itself and the whole vehicle, but it was going to take the launch pad and most everything halfway back to the firing room in the explosion. Luckily, that never happened.

I got to know the [Kennedy Space] Center director, Dr. Kurt Debus, quite well, because every time we had an engine problem on a test stand, or anywhere, he wanted an explanation. I would roll up my blueprints and toddle over to his office and lay them out on his desk and explain to him what we did or didn’t do, and what the failure was. That was the technology we had—rolled-up blueprints. You can imagine today, I’d have done my Powerpoint charts, and taken my laptop over there, and shown him all kinds of animations. But everything we did was basically manual, and we worked with handwritten procedures.

We worked hard. There wasn’t any such thing as a 40-hour week. We basically worked around the clock, seven days a week. So it sort of became a way of life. The way I felt about it was, I grew up on a farm, nobody could work me harder than my dad. Working 15 hours a day was no big change for me.

The Perils of Rocket Fuel

ART REINERS, North American Aviation

NASA’s Marshall Space Flight Center [in Alabama] had about 11 different sites we were responsible for, including Cape Canaveral. We developed all kinds of course material to teach people how to build the Saturn I and the Saturn V.…We had programs we taught on how to go in and clean up a Saturn after it had been [test] fired. It wasn’t just a matter of take it out, wash it off, and bring it back. No, you had to go inside the tanks and wash them down. Once a man is inside the tank, he’s only good for about 10 to 15 minutes with a Scott pack [breathing apparatus], and then he’s out of air. So you had teams of people working the internals of these tanks. It was called confined entry, and we taught a program on confined entry. We did lose one man due to nitrogen. He ended up in a 100 percent nitrogen atmosphere one day, and that was the end of that….

We lost a man on the test stand because we had a liquid oxygen leak and the liquid dripped on the flooring of the test stand. The guy came along and saw it. It had built up into like a little icicle and he kicked it and it blew his leg off. He had on rubber shoes, which had some oil or something on them, and oil in contact with cryogenic is just disastrous.

We’d Blow Up the Bomb

PAUL CASTENHOLZ, Rocketdyne

The F-1 rocket engine was completely new because of its size. We had tested small engines, even the J-2 [used on the Saturn second and third stages], which was about half the size or less. But our operations with smaller sizes were never anything like the F-1.

We ran a test with the [F-1 thrust] chamber, and all of a sudden it blew up and wrecked the stand and damaged the chamber. The test stand was about 200 yards away from the place where we, the test crew, were surrounded by concrete and glass. I was there, and was horrified. The propellant is flowing out of big breaks, all over everything on the test facility, so everything is on fire. A very big fire, very damaging to the test facility, and we could see every bit of it.

The problem turned out to be combustion instability of the oxygen in very large chambers. We had never seen that in smaller chambers, because they were confined, and they had no chance of combusting in step form. Because we were carrying men on top of this vehicle, we could not stand any combustion instability, because it would blow the chamber apart, and probably decimate the people that were riding it.

We put hundreds of cameras in the thrust chamber, their lenses pointed to the combustion zone near the injector. We inserted pyrotechnic “bombs” in cavities [outside the chamber], and we’d blow up the bomb to determine how big of an explosion it would take [to cause the instability]. We took months to evaluate the amount of surge we could put into it.

After about two years we came up with a design that used dams in the injector face to form cavities, which were small enough to not allow surges. We ran some 50 to 100 tests, with absolutely no instability. So we thought, Well, we’ve beaten the problem of running a stable, very large thrust chamber with these propellants.

Boom Times in Cotton Country

JIM NOBLITT, Boeing

I originally came [to Huntsville, Alabama] in 1964, and it was a boom town. You couldn’t find a place to live. There wasn’t a rental place anywhere in Huntsville. They were turning cotton fields into real estate developments, so I bought a new house in a place called Hazeline Estates, and I will never forget the red mud and the varmints in that old cotton field. They had mice and field urchins of all kinds. [The Boeing office] was an old cotton warehouse in Huntsville that they converted into an office building.

We were fairly close to where the [rocket] test stands were, down near the Tennessee River. And the big event was the day they fired the Saturn V for one of the first times. They had an inversion layer over Huntsville, and the pressure wave from the rocket went up and hit that overlaying [air mass] and came down over the town. We had a guy across the street with bay windows, and they must have been vibrating an inch or two, those bay windows, because there was so much overpressure. That got everybody in town’s attention.

I bought my house in ’64, and in late ’66, when I moved out, the program was on a decline, and Huntsville went from a boom town to a bust town almost. I couldn’t sell my house for nine months.

Going to the moon was a dream. Getting off the planet, this whole thing, was something we’d all talked about. I can remember going to college and talking with one of my neighbors about somebody flying in space. She thought I was crazy, even the idea of getting a rocket and flying up into space and orbiting the earth—You’re crazy! That ain’t never gonna happen! I was from a small town, and that was almost unimaginable, there was no basis for believing that. Maybe Huntsville was the believers, I don’t know.

But you know, there’s also a mundane day-to-day. You’re doing a job, you’re an engineer, you’ve got some little niche in this whole grand scheme of things. You didn’t go to work every day thinking about some guy landing on the moon. I had a carpool, so you know, you get up in the morning, you get in the carpool, you talk about the events of the day. You didn’t talk about going to the moon. You talked about what you did this weekend, what you’re going to do next weekend.

The Cox Test

JERE DAILEY, Engineer, Boeing

We got to see the 500F facility bird [a dummy Saturn V used for testing] go out to the pad, to try all of the swing arms [on the launch structure] to make sure everything fit. They actually fueled it and unfueled it out there, just to make sure all of the equipment worked. They were concerned about winds coming up, and the natural damping and swaying characteristics of the vehicle.

One night, a Dr. Cox came in to the VAB, the Vehicle Assembly Building, and they did the “Cox test.” They had a platform about two feet away from the Apollo [spacecraft], and this was up toward the top of it. They had four guys with tennis shoes on, sitting at the edge of the platform, and they had a safety strap so they wouldn’t fall. Dr. Cox attached an accelerometer to the side of the [vehicle]. They had these guys push it with their feet to a certain distance, and then let it stop, to see just how long it would take to stop. Well, the first time was okay. He said, “Let’s do it again, and do it a little further.” So they did it a second time. There were three of us up on another platform—a NASA guy, another Boeing guy, and myself, standing there observing it.

During that test, the escape rocket [at the top of the Saturn V, designed to propel the crew to safety in an emergency] came loose on top of the thing. Well, this being a dummy bird, it was bolted to the inside of a ring. The other Boeing guy and I took off running. The NASA guy just stood there and watched it. We thought it was going to fall, but it didn’t. It just went down inside the ring and landed against the nose of the rocket. Anyway, out of that they decided they needed another swing arm.

All-Up Testing

WERNHER VON BRAUN, Marshall

In 1964 [head of NASA’s Office of Manned Space Flight] George Mueller visited Marshall and casually introduced us to his philosophy of “all-up” testing. To the conservative breed of old rocketeers who had learned the hard way that it never seemed to pay to introduce more than one major change between flight tests, George’s ideas had an unrealistic ring. Instead of beginning with a ballasted first-stage flight as in the Saturn I program, then adding a live second stage only after the first stage had proven its flightworthiness, his all-up concept was startling. It meant nothing less than that the very first flight would be conducted with all three live stages of the giant Saturn V. Moreover, in order to maximize the payoff of that first flight, George said it should carry a live Apollo command and service module as payload. The entire flight should be carried through a sophisticated trajectory that would permit the [Apollo] command module to reenter the atmosphere under conditions simulating a return from the moon.

It sounded reckless, but George Mueller’s reasoning was impeccable. Water ballast in lieu of a second and third stage would require much less tank volume than liquid-hydrogen-fueled stages, so that a rocket tested with only a live first stage would be much shorter than the final configuration. Its aerodynamic shape and its body dynamics would thus not be representative. Filling the ballast tanks with liquid hydrogen? Fine, but then why not burn it as a bonus experiment? And so the arguments went on until George in the end prevailed.

In retrospect it is clear that without all-up testing the first manned lunar landing could not have taken place as early as 1969. Before Mueller joined the program, it had been decided that a total of about 20 sets of Apollo spacecraft and Saturn V rockets would be needed. Clearly, at least 10 unmanned flights with the huge new rocket would be required before anyone would muster the courage to launch a crew with it…. Gradually we would inch our way closer to the moon, and flight number 17, perhaps, would bring the first lunar landing….

Mueller changed all this, and his bold telescoping of the plan bore magnificent fruit: With the third Saturn V ever launched, the Apollo 8 crew orbited the moon on Christmas 1968, and the sixth Saturn V carried Neil Armstrong’s Apollo 11 to the first lunar landing.

Riding the Barge

MYRON PESSIN, Michoud

After we built the stages at Michoud, we barged them over to the Mississippi Test Facility, which is now the NASA Stennis Space Center [40 miles away]. We tested them and barged them back to Michoud, where we refurbished them and sent them on down to the Cape.

Before they tested a flight-ready stage in Mississippi, though, we sent a test vehicle, S1CT, to make sure the test stand was safe. That barge came by our Michoud facility on the Intracoastal Waterway, at three o’clock on a Sunday morning. A lot was involved in going up the Pearl River into Mississippi. We had to dredge it, and we had to put in locks. Around the [test] stands we had a lagoon so that you could bring the barge right up to the stands. The locks were needed to keep the water up in that lagoon. So I came out on a Sunday morning, three o’clock, and rode the barge from New Orleans to Stennis.

It was very foggy, but there was a bunch of fishermen out. When the fog got too bad we had to nudge into the bank and wait till the fog cleared. You didn’t want to run over a bunch of fisherman. It should have taken about three hours; however it took about six because of the fog. And these fisherman would be sitting there in their boats, and here comes this huge barge, 200 feet long and close to 50 feet wide, with a tugboat behind it, and the tug is running dead slow, and it’s totally quiet because of the heavy fog. And suddenly this huge white thing—the barge was white—is looming out of the darkness. Scared the hell out of the fishermen.

The Pieces Had to Fit

ROCCO PETRONE, Director of Launch Operations, Kennedy Space Center

Everything was outsize. Among the impressive statistics about the Vehicle Assembly Building were its capacity (nearly twice as big as the Pentagon) and its height (525 feet, 30 feet shorter than the Washington Monument).

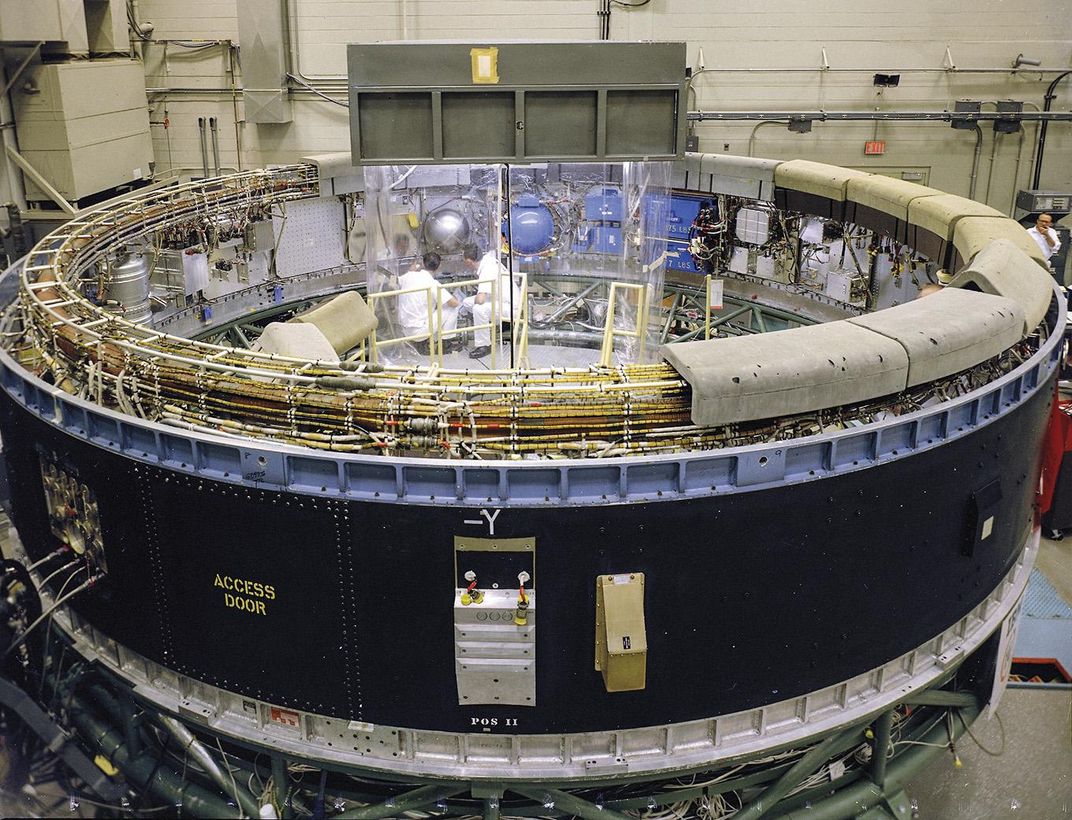

...I think of the VAB not as a building but as an intricate machine that assembled the vehicle in its final phases. People were surprised to learn that the various stages had never seen each other until they were introduced in the VAB drydock. The first stage had been built by Boeing at Michoud outside New Orleans, the second stage by North American at Seal Beach, California, the third by Douglas Aircraft [later McDonnell Douglas] at Huntington Beach, California, and the Instrument Unit by IBM at Huntsville, Alabama. The Apollo spacecraft that went on top of this stack were also introduced for the first time in the VAB.

Could these pieces, arriving from all over the country, play together? Every wire in every plug had to join exactly the right wire, with no electrical interference or change of signal strength, and a command signal had to work from the Instrument Unit through the third and second stages into the first. After the various stages had been put together they had to be checked out as an entity, and once this had been done you naturally don’t want to break the electrical connections again. When the Instrument Unit orders “Go right,” you don’t want an engine three stages down to go left. The pieces not only had to match each other, but also the ground equipment. Lines for the flow of liquid hydrogen from the ground had to match the stages, and so did others for the flow of liquid oxygen and still others for gaseous nitrogen and helium. Television monitors had to be designed and installed so that we could know what was happening in hundreds of places at any given time.

The skill required of the technicians working throughout the Kennedy Space Center had to be fine-honed. One of the legends had it that the crane operator who set the 88,000-pound second stage on top of the first stage had to qualify for the job by lowering a similar weight until it touched a raw egg without cracking the shell. Of the Cape’s 26,500 workers—the peak number in 1968—a high percentage were men and women who possessed such skills. One can speculate whether such a crew is likely to be assembled in one place again.

Stress and Depression

JAMES MIZELL, Engineer and Manager, Kennedy

Very, very exciting times. The time went by very quickly. I think I missed the entire Vietnam War because I didn’t watch television or read the newspapers. We had two children, and my daughter used to call me her bye-bye. I would wake her up at six in the morning and say, “I’m getting ready to go to work, goodbye,” and she’d say “bye-bye.” When I came home at night it was usually 9 or 10, and she was already in bed asleep. It was very, very difficult on the wives and on the husbands in those days.

I remember later on in the program, another guy and I counted 75 people out of our offices who had divorced. Seventy-five, and that didn’t include just the men, that was the ladies also. The tensions were just so tight.

In those days we didn’t have any mental health counseling as we do today, no psychological training. Most of us came out of the service, and had very thick skin. We had been through boot camps. We had been through all sorts of war, and it was a very, very harsh environment where we had been. That meant that we were rather tough on others, as well as ourselves. It was looked upon as a sign of weakness not to be able to work the maximum number of hours and handle the most stressful situations. There was no such thing as saying you couldn’t do something. That was one reason the program was successful, because the people devoted 110 percent of their mind and their ability on the problems that existed.

Alcoholism was very, very prevalent. People were very much depressed, especially those that couldn’t perform to the same level of the ones who were outstanding.

[There was one] case where one of our workers was caught out working unauthorized on a Saturn V going to the moon, at 3 in the morning. And he was making some very, very critical changes to the missile. The guy had severe migraine headaches, and he would get into these headache situations under stress. He would begin to have delusions. I asked him, “What were you doing there?” He says, “I was at home and I got one of my headaches, and I thought that we had that system set wrong for the mission. At 2 in the morning, I got up and I came back out and I was setting it right prior to liftoff.”

So Many Things That Could Ruin You

WILLIAM LUCAS, Director, Propulsion and Vehicle Engineering Laboratory, Marshall

You knew that there were thousands of things that could go wrong, that you could do nothing about. When you flew airplanes, there weren’t very many things that an alert crew could not fix so that you could at least land. If one engine goes out or you blow a hole in the wing or whatever, you still had a chance. But we knew that at any time, one lousy little 25-cent part somewhere could cost you the whole ballgame, and there was nothing you could do.

I’m sure a person who came in off the street, someone not associated directly, was excited just to see a [Saturn launch]. But a poor guy’s sitting over there digging his thumbs into his fingers. Or some would use little rubber balls. There were little grommets that were used on the command module, and I know Rocco Petrone used to always have one of those he’d be squeezing during this period of time. This was great tension. Not that you hadn’t done something you should have done. It was the knowledge that there were so many things that could go wrong that could ruin you.

Gasping for More

CHET JEZIERSKI, one of the artists commissioned by NASA to document the Apollo moon program

Having been at multiple space shuttle launches, they can’t compare with the Saturn V. Because of the sound, and the overall impression of what was happening. It was very dramatic. The shuttle gets up and leaves the pad almost immediately. It’s released, and the solid rockets are ignited, and it gets up and moves away. But the Saturn V just sat there. It sat on the pad, and the clouds of the exhaust blast came out the trenches at the bottom of the pad, and then suddenly, without any noise, it began to rise.

As it got up in the air, it began to give off this crackling noise, and it rolled over you like thunder. You felt it in your gut, that there was something very ominous happening. It demanded your attention. And seeing that happening, right in front of you, you felt you were seeing something that was very important.

And it’s over in a matter of two minutes. And you’re left gasping for more. That’s what I wanted to do immediately, was to see it all over again, because it was so incredible.

SOURCES: Lunney: NASA oral history; Reiners and Dailey: from Loretta Hall, Space Pioneers: In Their Own Words, Rio Grande Books, 2014; Von Braun and Petrone: from Apollo Expeditions to the Moon, NASA, 1975; Mizell: oral history, Brevard County [Fla.] Historical Commission; Lucas: oral history, University of Alabama in Huntsville. All others: Air & Space interviews.