The Wasp Engine’s Great Leap Forward

The only aircraft engine to be designated an historic landmark.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/c2/26/c22621a4-aec8-4aa1-b09f-ba587fa88dbe/11l_aug2017_r1300seriesnasm_live.jpg)

Advances in propulsion are what drive aviation development. Innovative airplanes almost always start with innovative engines, and the airframes follow. In 2016, the American Society of Mechanical Engineers celebrated just such an engine. The society designated the Pratt & Whitney R-1340 Wasp a technology landmark, the organization’s highest award, because the Wasp singlehandedly brought about a leap forward in aircraft performance and economics. The tale of its development is still fascinating.

The story can be told as a series of meetings among ambitious young designers, dealmakers with burning needs, and inflexible government contractors. The Wasp’s manufacturer, Pratt & Whitney, was at the time a humble machine tool company with no connection whatsoever to aviation. Thanks to a risky bet on an unproven technology, today it’s one of the world’s dominant builders of airplane engines.

At the center of the Wasp’s creation was Frederick Rentschler, scion of a well-connected Ohio industrial family. The family probably assumed that the dutiful son, who’d grown up working in their foundry, would one day inherit and run the family automobile engine manufacturing firm. And he might have done just that if it had not been for World War I. The Princeton graduate enlisted, and in 1917, as a first lieutenant in the aviation section of the U.S. Army Signal Corps, he was tasked with inspecting Hispano-Suiza engines built under license from France by the Wright-Martin Company in New Brunswick, New Jersey, and Long Island City, New York.

Young Rentschler found the work fascinating. These engines were not that different from those he was familiar with in automobiles: reciprocating pistons and cylinders arranged in rows, with liquid coolant circulating through the engine block and a radiator to dump excess heat. As the war wound down, Wright-Martin’s output tapered off, and Rentschler rejoined civilian life. For a time he ran Wright Aeronautical Corporation as president, until the board of directors, mostly bankers, decided not to reinvest profits for future engine development as he wished. In his mind, without investment in product development, the company was doomed. He resigned and spent months, including some time in a hospital due to illness, pondering the aircraft propulsion industry and how to jolt it from complacency.

Industry was at that time deeply invested in liquid-cooled engines, primarily large V-12s producing in excess of 400 horsepower. It was the conservative, low-risk solution for an aircraft engine, despite its well-known drawbacks: The required cooling system added weight and complexity, and radiators and coolant lines were vulnerable to battle damage, leakage, and subsequent engine failure.

In its time, Rentschler knew, the water-cooled Hispano-Suiza had been the best engine available; it powered the preeminent Allied airplanes in World War I. But Rentschler began to embrace the idea of a radically improved air-cooled radial engine—a central crankcase with cylinders arranged in a circle around it—that would produce as much power as the biggest liquid-cooled engines of the day. Opponents of the type thought the shape created too much drag compared to the slim in-line configuration of a long, thin V, but Rentschler’s own conclusion, reached also by engineers whose opinion he valued, was that a well-designed radial would save so much weight that the added drag would be immaterial. While he was still at Wright, he had led the company during development of a radial called the Whirlwind, so he was familiar with the type. The Wright Whirlwind would later power Charles Lindbergh’s Ryan on his flight to Paris.

Rentschler’s first meeting of note was during the winter of 1925 with James Cullen, a friend of his father and the president of the Hartford, Connecticut-based machine-tool company Niles-Bement-Pond. That meeting led to several more over a period of six weeks; during one, Cullen told Rentschler that one of his company’s subsidiaries, the toolmaker Pratt & Whitney, had extra production space and money to spend. Should Rentschler have a worthy idea and a waiting customer, he would have the factory and finances to pursue it.

Meanwhile, down in Washington, D.C., Rear Admiral William A. Moffett, champion of the airship and expectant father of two aircraft carriers aborning at shipyards in New Jersey and Massachusetts, was scheming. Moffett’s life as the head of the Navy Bureau of Aeronautics was consumed with meetings—meetings with Congressmen, with Navy and civilian engineers, and with newspapermen. Moffett had a vision for naval aviation, a fire in his belly to make it real, and a talent for getting his message to the public.

The Washington Naval Treaty, which limited navies from expanding their fleets of capital ships, had caused work to stop on the battle cruisers Saratoga and Lexington. Moffett discovered that the treaty allowed him to convert both ships to aircraft carriers. He would need hundreds of airplanes to equip the ships for fleet service. The Navy was keenly aware of the liquid–versus–air-cooled controversy and even more sharply focused on reducing the size and weight of all its aircraft. Radial engines lacked all the plumbing of the big V-12s and could take the pounding that comes with landing on a carrier deck without cracking brazed joints in radiators—since there was no radiator—and springing leaks. Radials weighed less, provided faster climb rates, and simplified maintenance: In short, they were the very engines the Navy needed.

In the period after World War I, Eugene Wilson, a Navy commander who served under Moffett during this era, was plunged into the internecine battles over the military budget. In his autobiography, Slipstream, he relates the story of the role Moffett played and how the admiral’s no-holds-barred style ended up furthering Rentschler’s cause. Among Moffett’s earliest directives to Wilson was to keep tabs on Army General Billy Mitchell, the author of the Army’s long-range bombing doctrine and, in political terms, the Navy’s mortal enemy. Mitchell was moved to Texas to get him as far away from Washington as was practical; the general had earned his banishment by behaving like a bully. But Moffett knew that when it came to Mitchell, there was no such thing as a safe distance.

Enter one Chance Milton Vought, founder and president of the Long Island City, New York aircraft manufacturer bearing his name. It must have been sometime around early 1924 (Wilson’s account doesn’t say precisely when) that Vought showed up at Wilson’s offices, but instead of his usual sartorial splendor, he was sporting a “dilapidated tweed suit, under a moth-eaten coonskin coat, wearing a lean and hungry look, and talking very poor.” Vought’s company was nearly out of work, and he had come begging. Wilson surprised him by advising him to design something new instead of bleating for orders for more of the same old airplanes.

Vought had a ready retort: Give him an all-new engine weighing no more than 650 pounds and producing no less than 350 horsepower, and he’d build a world-beater. Without realizing it, Vought had just written the specifications for Rentschler’s new engine. But after Vought left, Wilson’s first call was to a more familiar supplier, Wright Aero. They were a known quantity in the aviation business as well as in the Navy.

Wright’s Whirlwind put out 200 horsepower, and its newest engine, which would become the Cyclone, was advertised as capable of 450. What was needed was something in between. But when the Wright executives, Charles Lawrance and Guy Vaughan, met with Wilson the next morning, they were not enthusiastic. They needed a third engine like they needed a third eye, but this was the Navy, a good customer, and they agreed to scale down the Cyclone into a new concept engine carrying the name Simoon, a variation on an Arabic word for a hot desert wind. The Simoon would never see the production line, but Wilson could not have known that yet.

Rentschler, now unemployed, was armed only with an idea and the awareness that the people at Wright took their sweet time with new projects. So on an April morning in 1925, he boarded a train for Hartford and another meeting, this time with Clayton Burt, general manager of the Pratt & Whitney division. He had with him a letter of introduction from James Cullen. Burt showed him various facilities, among them a building owned by Pratt & Whitney that had been home to the Pope-Hartford Automobile Company, now crammed with the local shade-grown tobacco that served as a wrapper for premium cigars.

After his tour of the factory, Rentschler met with a group of men. At the time, there was nothing like a PowerPoint presentation. He simply began to talk, describing the Curtiss D-12, a 500-horsepower engine considered the pinnacle of U.S. engine design. He proposed an air-cooled engine in a radial configuration that would equal the horsepower of the D-12 but weigh less. For this, he would need use of the Pratt & Whitney facility, some equipment, and a few workers, plus $250,000 to $500,000 for a prototype and another $1 million for production. He further advised the gathering that before he left Wright, he had invited those he considered the company’s ablest employees to join him, but urged all to stay where they were until he was sure the new engine would be built. All had pledged interest.

Rentschler had spoken with the three men at Wright whom he most respected. First among them was George Mead, a brilliant designer who had been trained at MIT and mentored by legendary engineer Henry Crane. If Rentschler was the Steve Jobs in this startup, Mead was his Wozniak. He also confided in Andy Wilgoos, who was a gifted and intuitive designer, and Donald Brown, a third indispensable member of the Wright team. All three realized the world was changing quickly, and they wanted to be at the forefront of development.

Considerable time had passed after Vought’s encounter with Wilson before Rentschler went to Washington for a meeting to see what the Navy was up to; in the interim, he’d learned a lot by talking with Vought, and this visit could later be seen as a watershed event. Rentschler pitched Wilson on the need for the Navy to maintain competition among suppliers, an idea to which Wilson was already sensitive. In those days, “monopoly” was a dirty word. Congress took every opportunity to sniff out antitrust violations in war contracts. Rentschler reminded Wilson and the Engine Section staff that Curtiss was wedded to liquid cooling and that Wright moved at a glacial pace. But according to Wilson’s account, what really stunned the gathering was Rentschler’s suggestion that Curtiss and Wright might well merge (as they eventually did in 1929). If that happened, the Navy could get stuck with a single supplier. He now had Wilson’s complete attention, but Wilson had no money.

Moffett made the policy decisions, so the merry band moved to the admiral’s office to thrash out the matter. Wilson recalled in his memoir that Moffett immediately grasped the importance of a new engine and a new competitor. Wilson did some quick arithmetic and realized the new engines would save money, so Moffett ordered him to scrap the notion of modifying old Liberty engines for Navy use. “Congress had no interest in performance; they wanted to save cash,” Wilson wrote. Still, Wilson promised Rentschler that the Navy would pay him $90,000 upon delivery of six working prototype engines. Back in Hartford, Rentschler was open with the Pratt & Whitney executives about the absence of a signed contract for the engine’s development, but seemingly undeterred, they told him they would call Cullen with a decision and Cullen would call him. A few days later, Rentschler got the phone call: He would have his engine.

On the very next night, he met with Mead, who vowed to resign from Wright and start on the new engine project immediately. No, Rentschler urged; think it over for two weeks. During that time, Rentschler finalized the contract with Hartford, then gathered Wilgoos and Brown. Wilgoos happened to be Mead’s neighbor, and his house at 22 Wellesley Road in Montclair, New Jersey, had a detached garage where he and Mead could work. By July they needed an extra hand, and Earle Ryder came on board, to be paid personally by Rentschler. The other ex-Wright employees had to wait until the team opened the facility at Hartford on August 3 to get their first paychecks.

Mead had designed an earlier radial engine in which the usual arrangement was reversed: Instead of a solid, forged crank to which the large end of a two-piece master connecting rod would be attached by a bolted cap, the Wasp would use a two-piece crankshaft and a solid one-piece master rod; this strengthened the master rod enough to withstand as many revolutions per minute as the pistons could manage, and allowed for a lighter and stronger crankshaft. Mead’s patent application for the arrangement also shows a means for compressing the two halves of the tightly fitted splined crank throw for assembly and also for driving the two halves apart for disassembly.

The crankcase was forged as two halves, the split between them coinciding with the plane of the all-steel cylinders. Accessories were all grouped in the back, leaving the front of the engine clean. It was this concatenation of design features, none individually new but novel in combination, that created an engine of high power and low weight. More importantly, the engineers had happened upon a balance, whether they were aware of it or not, that would distribute the internal forces upon the working engine in such a way that each part was configured in the optimal way for the job it had to do. It would be, in a word, dependable.

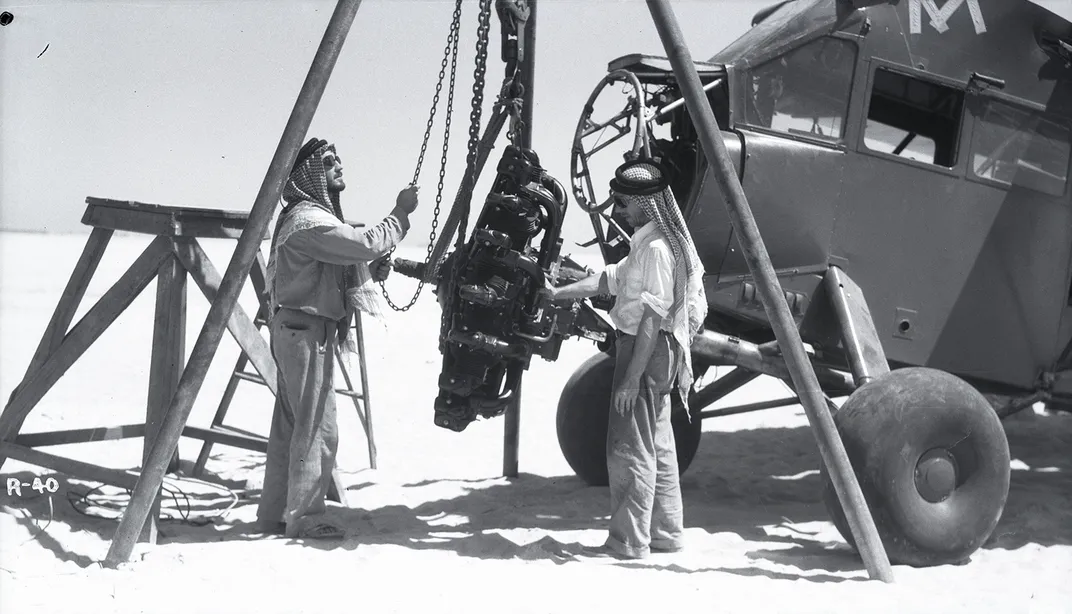

The engine passed its endurance tests with ease and got its name when Rentschler’s wife Faye learned that the team was ruminating about a name related to the buzzing noise of bees; she came up with “wasp” and Wasp it became. It had come in at 650 pounds, and the third time it was started up on the test stand, it delivered 425 horsepower. It made its first flight on May 5, 1926, in the nose of a Wright Apache. To meet a challenge from board member Edward Deeds and win a holiday turkey each, the little group designed the first Wasp engine in less than a year and had it completely assembled by the deadline: Christmas day, 1925.

In his portraits, even those taken at what should have been moments of triumph, Rentschler looks grim. Then again, back in the 1920s, people didn’t smile when they posed for photographs. But in his memoirs, his words are those of a happy man. Of his beloved Wasp, he wrote: “It ran as clean as a hound’s tooth and was actually just the thoroughbred that it looked. These characteristics had never been previously achieved in an aviation engine.” The team knew they had built something special, but even then, they couldn’t have known that they had, in fact, built an American landmark.