Digital Files and 3D Printing—in the Renaissance?

3D printing is a new technology that seems poised to change the world, but its origins date back all the way to the 15th century

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/20130301022134draughtsmans-contract-web.jpg)

3D printers and digital mapping services are making it drastically easier to produce infinite identical copies of anything, for better or worse, for humanitarian or for destructive purposes. A digital map can be accessed by anyone with a smartphone or computer and a replica of Michelangelo’s David can be made at home just as easily as an assault rifle. While the relatively new technology of 3D printing is proving popular with designers, fabricators and the general public, it hasn’t yet reached the ubiquity of the home printer. But it only seems to be a matter of time until desktop fabrication is as common as desktop publishing. The technology is getting cheaper and more efficient every year, and even though 3D printing has barely been established, engineers are already hard at work on 4D printing (the fourth dimension is time!). One ambitious company has recently caused a sensation on Kickstarter with its prototype for a 3D printing pen.

These latest drawing and modeling technologies are fascinating, but when did the idea of 3D printing originate? What are some of the earliest drawing and fabrication “machines”? To find the answer we go back to the days before copiers or even carbon paper, back to the Renaissance, to a man who invented digital reproduction in the original sense of the word.

Leon Battista Alberti was an Italian philosopher, scientist, architect and all around polymath who lived during the 15th century. Basically, he was your prototypical Renaissance man. Alberti is perhaps one of the most important and influential creative figures to come out of the Renaissance, although he is one of the less widely known. He believed that art and science were united by basic principles of mathematics, and among his many accomplishments Alberti defined the principles of geometric construction known today as central perspective and invented techniques for producing identical copies of paintings, sculptures, and even buildings without the aid of mechanical devices such as the printing press. This desire for a method of creating identical copies came out of Alberti’s frustration with the inadequacies and inevitable mistakes that result from manual reproduction techniques. In his excellent book, The Alphabet and the Algorithm (which I’m currently enjoying and have previously mentioned on Design Decoded), architectural theorist and historian Mario Carpo describes these techniques as “digital” reproductions.

“Alberti tried to counter the failings of analog images by digitizing them, in the etymological sense: replacing pictures with a list of numbers and a set of computation instructions, or algorithms, designed to convert a visual image into a digital file and then recreate a copy of the original picture when needed.”

By reducing images to carefully calculated coordinates and documenting the method by which the original was created, Alberti ensured that anyone could produce copies that were exactly identical to his original work. The numeric manuscripts, which were easy to copy without error, represented a type of Renaissance file transfer.

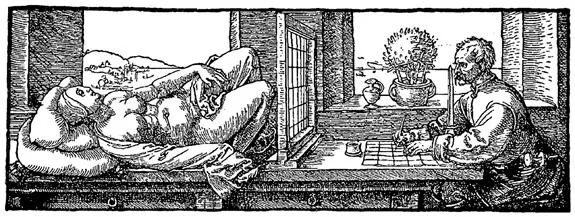

Alberti’s most famous invention dealing with reproduction is the perspective machine, which is still used by artists today. The setup he designed for transcribing images from reality looks something like a modern Battleship game board. A gridded wooden screen separates the artist, whose eye is held at a fixed point at the center of the screen, from his subject. From the artists’s perspective, the object to be represented is mapped onto the framed grid; this way, the artist can accurately recreate the image on a paper that has been divided into a matching grid. The distance between these grid lines determines the “resolution” of the image, to borrow a term from the parlance of digital technology, and to a limited extent, the accuracy of the reproduction. If we wanted to extrapolate a little more to further make the comparisons with contemporary digital technology, we could even call these grid divisions pixels. Alberti’s perspective machine represented an important step in his quest to eliminate variability from reproduction, but, because it still relied on the hand of the artist, it did not completely remove human error. Alberti continued to develop math-based techniques of reproduction.

One of the most compelling works of true “digitization” is Alberti’s book containing a map of Rome, the Descriptio Urbis Romae, created around the 1440s. The book, however, does not contain an actual printed copy of a map. After painstakingly measuring and drawing the streets, temples and landscape of Rome, Alberti wanted to distribute his map, but he didn’t believe hand-made copies could accurately reproduce his original. While the technology for mechanical reproduction was in its nascent stages, its use was not widespread and its potential remained unrealized. Alberti’s solution? He transcribed his carefully crafted map into a series of polar coordinates measured from the peak of the Capitoline Hill. These coordinates are collected in the Descriptio in lieu of a hand-drawn map. His idea was that readers could transcribe an identical version of his map themselves, using Alberti’s notes and an astrolabe-like device that consisted of a rotating ruler attached to the center of a disc divided into degrees. Alberti’s coordinates and instructions are, as Carpo noted, a primitive type of algorithm—the same process that drives today’s computer-designed architecture and the software controlling digital fabrication machines.

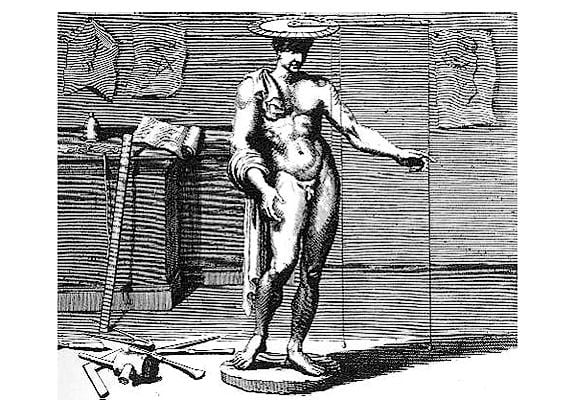

But perhaps the most impressive of Alberti’s inventions is his technique for reproducing sculpture. In his treatise on figural sculpture, De statua, Alberti described a method of reproducing identical copies of sculptures using traditional tools and basic computation. First, the artist/copier takes precise measures of the sculpture’s height, width and its various diameters using the proper tools—t-squares, angles, etc. The main components of the sculpture are measured and documented numerically —“scanned,” essentially—in relation to one another and to the entire length of the statue. To get more precise measurements of the statue’s details, a device of Alberti’s invention known as the definitor or finitorium is installed atop the statue. Similar to the device used to create the map of Rome, the finitorium is a flat disc inscribed with degrees joined to a movable arm, also inscribed with measurements; from the end hangs a weighted line. By rotating the arm and raising or lowering the plumb line, it is technically possible, although surely infuriatingly slow, to map every point on the statue in three-dimensional space relative to its central axis. That data could then be sent to a craftsman who would use it to create an identical copy of the original statue.

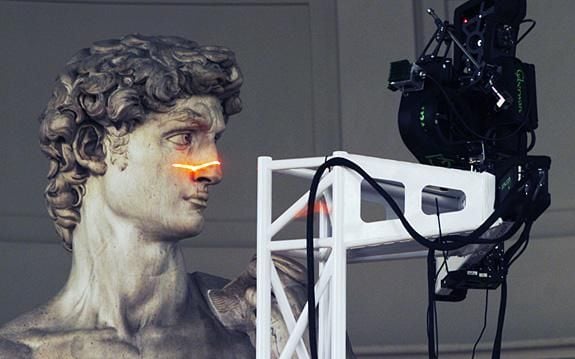

This brings us back to 3D printing. There are many different kinds of 3D printers that create models from various types of plastic, but they all essentially work the same. The printer processes digital blueprints—coordinates located in virtual space—of an object created by modeling software and digitally “slices” the model into pieces small enough to be created by the machine. These components are layered on top of one another and bound together almost seamlessly, creating an identical physical reproduction of the original digital model. 3D scanning and printing is obviously much, much faster than Alberti’s method, but it functions in much the same way—except, of course, for the automated documentation of an object’s shape and the robotic construction using synthetic materials. Alberti even boasted that his methods could be used to recreate different parts of a sculpture at different times or in different locations and that his method was so exact, these individual components could be seamlessly assembled to create an exact replica of the original—a process that sounds a lot like modern manufacturing.

With both the old and new technologies, any statue—any thing, really—can be theoretically recreated at any size anywhere. Take, for instance, Michelangelo’s David. In 2000, Stanford labs created a nearly perfect digital 3D replica of the David that users can rotate and manipulate to examine the sculpture in much closer detail than would be possible if they were to visit the original in Florence. From six tons to thirty-two gigabytes, the digitized replica of Michelangelo’s masterpiece can now be reconstituted in the studio of anyone with a high-speed internet connection, enough hard drive space and some automatic fabrication equipment. The flexibility afforded by the digital model creates entirely new ways for people to experience the statue. For example, an enormous golden reproduction known formally as David (inspired by Michelangelo) was created in 2005 by conceptual artist Serkan Ozkaya and is currently installed in the 21c Museum in Louisville, Kentucky.

3D printers and other forms of digital fabrication will possibly change the way we live in the future. But the ideas behind these paradigm-shifting machines have been around for a long time, and the dream of sharing and creating identical copies dates all the way back to the 15th century. Scientists, artists and philosophers like Alberti lacked the technological sophistication to make their ideas practical, and, in some cases, they lacked the imagination to even realize the possibilities of what they proposed. But that’s no longer a problem. We have the technology. The designers of tomorrow will realize the dreams of the Renaissance.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Jimmy-Stamp-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Jimmy-Stamp-240.jpg)