D.C.’s Artisan Chocolate Makers Show Off Their Sweet Labor of Love

Leaving no task undone, this husband-and-wife team demonstrate their process for producing chocolate

According to plant biochemist Adam Kavalier, science has confirmed that chocolate actually is a food of love. He first studied cacao as a medicinal plant while he was working on his Ph.D and became intrigued by the bean’s amazing chemistry. So intrigued, that seven years ago, Kavalier began making chocolate in his Manhattan apartment. He met his now-wife Kristen in a yoga class and captured her chocolate-loving heart instantly by giving her four homemade chocolate bars on their first date.

In an interview, Kavalier described how chocolate has the ability to increase the brain’s level of serotonin—the “feel good brain chemical” that elevates mood; it also contains phenethylamine (PEA), a neurotransmitter that triggers endorphins. Chocolate also contains anandamide, the so-called “bliss chemical” that produces a feeling of euphoria.

Last September, Adam and Kristen moved to Washington and began making chocolate in Union Kitchen, a remarkable operation that provides production space for young entrepreneurs. They call their chocolate bars “Undone Chocolate” because they want “to produce unprocessed chocolate and undo (or unravel) the relatively unknown story behind everyone’s favorite food.”

They make three kinds of chocolate bars: “Nourish” has a full flavor plus high levels of antioxidants; “Replenish” is dark chocolate that has a sprinkle of pink Himalayan salt loaded with trace minerals; and “Arouse” contains cinnamon, cardamom and chili pepper—all ingredients that, like chocolate itself, have aphrodisiac qualities.

Their kitchen is awash in the sights, sounds and smells of chocolate making. They select cacao beans from farms in Guatemala and the Dominican Republic that use ecofriendly organic practices. Beans are harvested from a fruit pod and fermented, then dried and shipped to Undone Chocolate’s kitchen in 150-pound bags. Adam tests the beans in a mass spectrometer, which he explains gives a “chemical snapshot” that identifies beans with the highest antioxidant level. He tosses aside small or cracked beans so that all are a uniform size, and roasts them on trays for one hour at a low temperature.

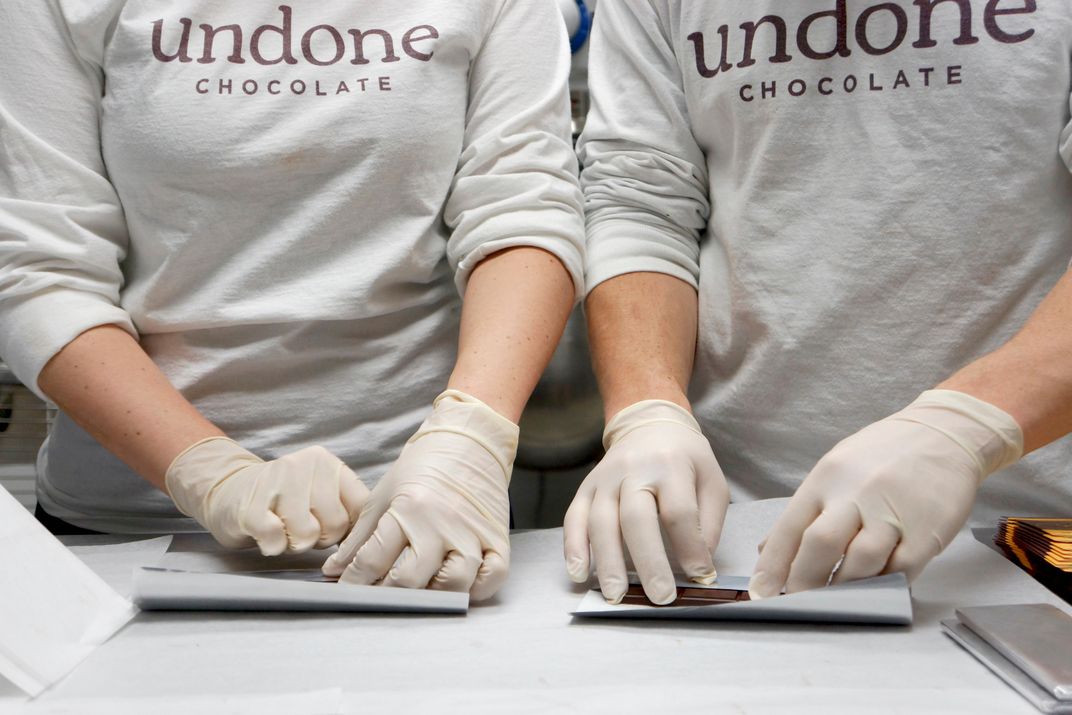

The beans are then “winnowed” in a vacuum machine that separates the nib from the shell. Organic cane sugar is added to the nibs and placed in a mixer for three days; the chocolate is then placed in covered pans to age—a process that lasts anywhere from two days to two months. The last process—tempering the chocolate over heat—is delicate, with Adam gently stirring the liquid until it has the right “feel.” It is then poured into chocolate bar templates; when cooled, the chocolate bars are carefully removed from the molds and carefully trimmed by Adam’s mother Sandy. The final touch is when each bar is carefully wrapped and packaged “as if it were a present.” Sandy, a yoga teacher, says that she finds chocolate making “meditative.”

Time-intensive and demanding, craft chocolate making is by its very nature a labor of love. Adam spends up to 18 hours a day in the kitchen; Kristen has a full-time day job, but spends evenings and weekends contributing her expertise in business and marketing. They launched their first Undone Chocolate bars in December; they now produce 2,000 to 2,500 bars per month, and their chocolate’s popularity is expanding rapidly.

In his guise as a plant biochemist, Adam explains that today’s science validates chocolate’s ability to enhance cardiovascular health and promote good cholesterol; it is also, he notes, the only natural agent that has a “bliss chemical.” But above all, both Kavaliers declare, “it really is a love food.”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Amy_Henderson_NPG1401.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/0c/b1/0cb1176c-a564-4001-8b0c-c0985af1c240/final-product.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/10/8e/108ea0a5-ff93-435e-bfa6-eedfab05cf3f/step7-wrap3.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Amy_Henderson_NPG1401.jpg)