Airbus Demos A Near-Silent, Zero-Emission Plane

The E-Fan 2.0 is the first step on the road to all-electric and hybrid flight

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/44/64/446441ee-d800-45d3-aeda-2df3a262fc16/14739964172_d36e7c97ec_k.jpg)

Last week, an Airbus-branded plane soared through the sky over Farnborough, England. But for spectators on the ground at the annual Farnborough International Airshow, something was missing: sound.

That’s because the aircraft being demonstrated was Airbus Group’s prototype all-electric E-Fan 2.0. Scheduled to go on sale in late 2017, the eerily silent two-seater is the first step in the company’s alternative-fuel roadmap. Development of the E-Fan and subsequent models, according to Chief Technology Officer Jean Botti, should lead to an 80- or 90-passenger commercial prototype around 2030.

When the E-Fan 2.0 hits the market, it will be used primarily for pilot training. The 500-kilogram plane is powered by a pair of 30-kilowatt electric motors that work together to drive two ducted fans attached to the body behind the cockpit. This electric drivetrain can propel the craft up to 124 miles per hour, with a cruising speed of 99 miles per hour. A third, smaller motor attached to the front landing gear allows the plane to accelerate up to about 37 miles per hour during taxiing and landing. CO2 emissions are, of course, nil.

As Botti points out, the most important piece of the puzzle is the battery. Here, power density is key. “It’s not like a car, where you can get 1.2 or 1.5 kilowatts per kilo[gram] and make a car run for an okay distance,” he says. “The problem we have in aeronautics is gravity; you have to get up to 7 to 10 kilowatts per kilo[gram].”

Airbus partnered with the Korean company Kokam on the batteries for the current iteration of the E-Fan, though they haven’t yet settled on a battery for the final version. The power supply consists of 120 lithium-ion polymer cells tucked into the wings. Together, the batteries last for 45 to 60 minutes, with a 15-minute reserve; they can be recharged in about an hour. Airbus is also developing a quick-change mechanism so that the cells can be swapped out easily on the tarmac between flights. There is also a backup battery in case of an emergency landing.

Approximately one year after the E-Fan 2.0 debuts, Airbus plans to release a four-seat version, the E-Fan 4.0. In order to extend its possible flight time to three hours, engineers will add an engine that will function much like that of a hybrid car—except that this engine will never be used as a means of propulsion. When the battery depletes below a certain level, the engine will kick in and begin spinning a generator, which in turn will deliver power to the battery packs.

But Airbus, best known for its commercial airliners, doesn’t plan to make a business out of these relatively tiny aircraft. Price tags have not yet been added to the two- and four-seaters. “We’re doing all this to learn and to scale up,” says Botti. “The goal here is to develop the technology to [build] a regional aircraft, an 80- to 90-seater.” Small crafts, like the E-Fan 2.0 and 4.0, will be under the brand name Voltair, a newly-formed subsidiary of the Airbus Group.

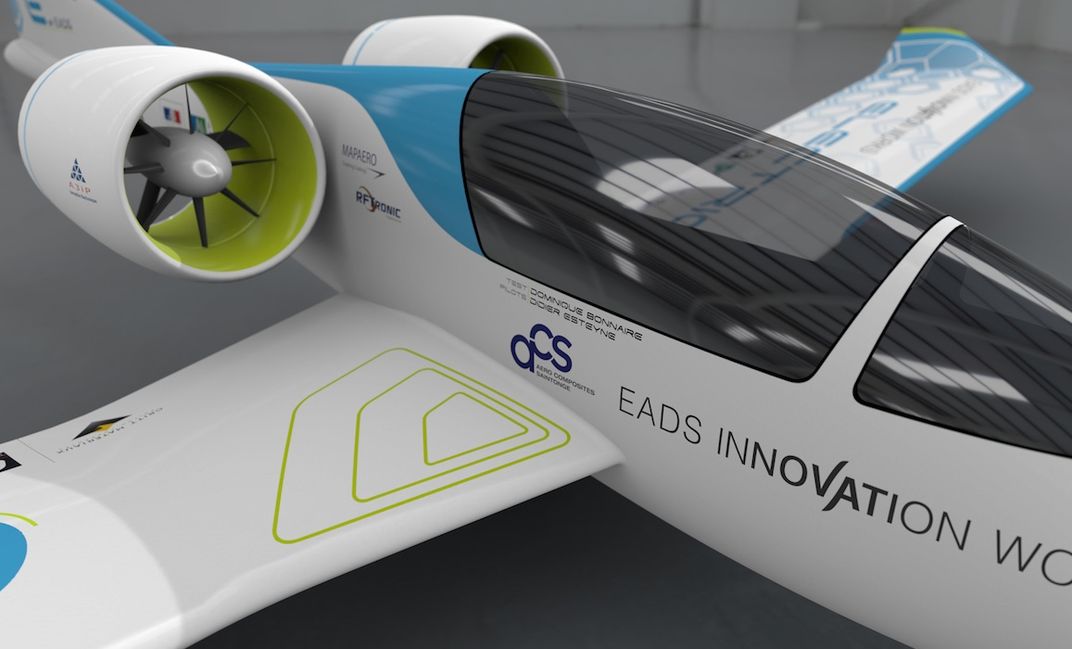

Larger planes will be built on a hybrid platform called E-Thrust. Developed in collaboration with EADS Innovation Works (the research and development arm of the European aerospace consortium) and Rolls-Royce, this drivetrain will use its gas turbine engine for extra thrust during take-off in addition to providing power to the batteries while the plane is cruising.

All this work fits into a larger effort initiated by the European Commission in 2011, called Flightpath 2050. Two of the program’s primary goals are to reduce CO2 emissions from aircraft by 75 percent and cut their noise by 65 percent—all by the year 2050. While Airbus is not sharing specific projections for the efficiency of its hybrids at this time, crafts like the E-Fan 4.0 should easily meet these goals, since they only burn fuel for a fraction of flight time and electric motors are virtually silent when compared to gas engines. But, according to Botti, hybrid flight might not be enough to reduce the footprint of larger 350-passenger commercial airliners. “We think the future will call for biofuels instead of electricity,” he says.

That doesn’t mean that larger planes don’t also have something to gain here. Botti says that what’s learned during the development of these electric and hybrid systems could trickle down to conventional aircraft. Increased battery efficiency, for example, could lead to more-intelligent power usage or new power sources for landing gear.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/me.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/me.jpg)