Could This San Francisco Startup Transform Garbage Collecting?

Compology uses sensors and software to plot truck routes to empty only dumpsters that are full

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/3d/96/3d9638d8-eca2-43ff-8777-2907e124a1c4/compology.jpg)

When you think of waste management, you may not think about all the different parties that sort and transport garbage from its many origins to a landfill or recycling center. But overseeing and optimizing that process is where Compology, a new kind of waste management company, shines. The San Francisco-based startup offers a suite of sensors and a software platform that work in concert to monitor containers and driver routes to cut back on the cost of picking up half-full dumpsters.

The market is there. Many cities have set zero waste goals, with the idea of making most waste recyclable or reusable. In the meantime, there’s still a lot of trash accumulating. According to a 2013 report from the World Bank, global waste is on track to triple by the year 2100. Even by 2025, the cost of dealing with so much trash will hit $375 billion, with developing nations the most impacted by the price.

Co-founder and CEO Jason Gates recently took time to talk trash with Smithsonian.com.

How did the idea for Compology come about?

I'd been working in the waste business on the generator side, specifically in construction and demolition debris and material, and more specifically on construction sites in New York City, where I started to learn about about different tools available to waste haulers to run their businesses.

My co-founders and I saw an interesting trend: there were lots of investments in waste processing technology. What I mean by processing is what happens after waste is collected, whether it’s taken to a landfill or recycling center. There’s investment in drones built to oversee how landfills are managed, in recycling sorting technology, and in technology for turning waste into fuel.

But there’s not a lot of investment on the hauler side. Many of the hauler-side tools developed in the early 1990s and 2000s are still being used. My co-founder Ben Chehebar has more of a tech background than I do, and he noted that the cost of providing technology at scale has come down, and that there is interest in connected sensors. The idea for Compology really grew out of those observations.

How did you begin tackling some of the industry problems you observed?

Our first product was designed specifically for commercial containers that can hold two to eight cubic yards. Most people have seen these in the wild; it’s a container bigger than the ones found at homes or apartment buildings. These are the kind of massive containers that you might find behind a grocery store and requires a truck with forks to pick it up, dump it and put it back down.

What we found with those containers specifically is that many were picked up under 60 percent full. We thought that we could offer companies tremendous operational cost savings with tools to service containers only when necessary.

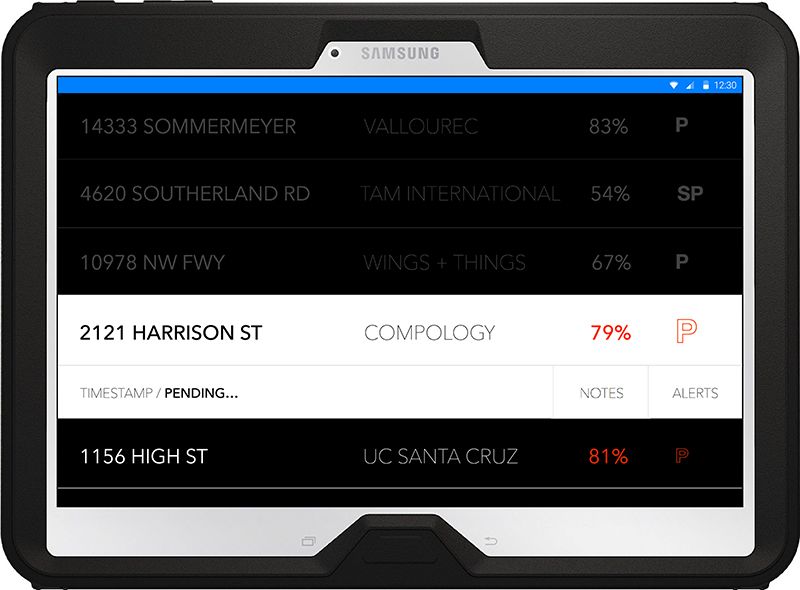

Our physical sensors retrofit into containers, and our software uses the information about how full a container is in real time. Instead of sending trucks out on the same set collection schedule to 100 containers every Monday, whether those containers are full or not, our system builds new routes for a fleet each morning based on which containers actually need to be serviced.

By doing all of this, we could show that you can cut the cost of pickups by 40 to 50 percent. That’s tremendously impactful.

How do all the moving pieces—the sensors, the backend—work together?

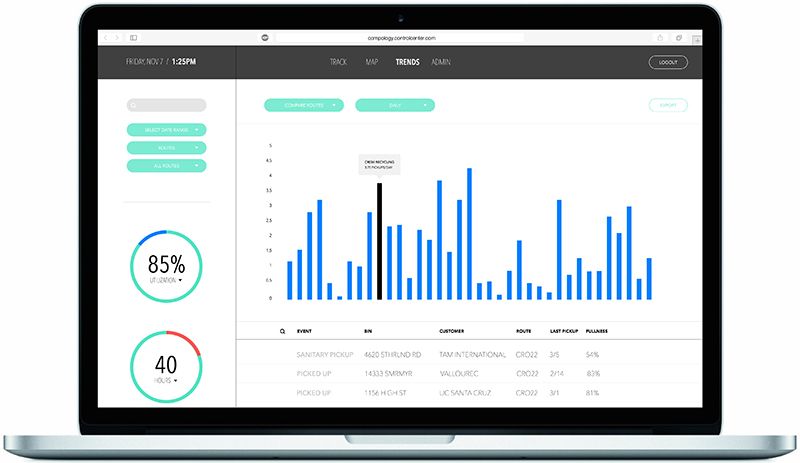

We take a unique approach to monitor container fullness and use cameras to take pictures of the inside of containers, then pull down GPS coordinates, process the image and determine how full a container is. Fullness reports flow into web-based tools we build. A dispatcher, route manager, customer service or even a salesperson at a waste hauler—whoever needs to know how containers are performing—can monitor the web-based dashboard. Think of this like a control center, managing a fleet of trucks but also containers.

A great example of when images become helpful is in identifying contamination, which has become increasingly important for composting both pre-consumer scraps from, say, a bakery, versus post-consumer waste such as restaurant table scraps. This also matters for recycling paper, cans and cardboard. The value of those materials dramatically decreases when there’s contamination.

It’s hard for haulers to provide granular feedback to pull contamination from the stream of incoming waste. For example, if a truck picks up from 70 stops, when a hauler dumps at a recycling center and sees contamination, how can he figure out where he picked up a bad load? With our tools, now our customer can go back and look at the images. Then our customer can provide that information to a supermarket or a restaurant along with an explanation of what the business is doing incorrectly and how to fix it.

Our tools are very driver-specific and tie together a lot of different aspects of hauling, as well as automate and automatically report information drivers used to have to log by hand, such as their load weights or which landfill is accepting loads. This also helps the dispatcher, who can see all of this on a dashboard at his desk.

What’s one major problem you solve for customers?

There’s a trend we’ve noticed, and it’s not unique to the garbage business. With technology in general, there can be a definitive return on a product, but folks often overlook or choose not to disclose the many hoops through which the customer has to jump to be able to realize the value. To put it another way, the juice may not be worth the squeeze.

We’ve designed our model in a way that we manage the technology from start to finish. We own the sensors, so we’re responsible for installation, maintenance and replacements. On the software side, what we offer is web-based, so there’s no software to install, and we’re constantly updating and improving in the same way that you see constant updates from consumer-focused internet companies. We remove the need for the garbage company IT guy to manage our tech, and our customers have been pleasantly surprised by this.

What’s changed for Compology this year?

As our tech continued to improve and we learned more about markets and haulers and became more established, we found that the same sensors we built for smaller units could be used in roll-off containers, the really big ones on construction sites that range from 20 to 40 cubic yards.

We’re very excited to have recently launched our new product offering, a suite of tools specifically designed to manage roll-offs. We pick up the whole container, bring it to a landfill, and then deliver it to a new customer or take it back to the previous one.

We launched with a select group of consumers at the end of 2015 and started really rolling out at scale the second quarter of this year. We’re still new, but the response from industry has been tremendous, as there are far fewer tools to manage roll-off lines versus a commercial frontload line of business. Our suite is a big win for the industry.

Garbage is often an afterthought, and in container service right now, more often than not, a hauler is at the mercy of customers, waiting for a call to come for a pickup. What we bring is predictability to roll-off lines, which in turn provides operational savings for all parties.

What's next for Compology?

We are working with Wastequip, the largest manufacturer of containers in the U.S.

We’re really excited to work with them because they recognize being able to provide best of breed tools to their clients, and we share the same client base, basically. We can have our tech pre-installed on all new containers fresh from the factory. We started shipping recently, and it offers a huge benefit to our shared customer base, makes our technology more accessible and gets it out there faster.

Another recent partnership is pretty close to home. We’ve partnered with Peninsula Sanitary Service, Inc. (PSSI), the hauler service for the Stanford University campus, which will use our technology campus-wide. PSSI is an innovator on many fronts and particularly forward-thinking. They understand the value, and we’re thrilled to partner with them.

Could Compology also be part of the future of residential trash collection?

Residential collection—in the way people traditionally think of it, a truck driving down a city block, stopping at every home—is tough from a dynamic routing perspective. Often, the houses are so close together that the incremental cost savings of skipping one home but servicing others is negligible.

"Pay-as-you-throw" models are popular in theory because residents would only pay for the waste they actually generate, as opposed to a flat rate each month. But those models have been tough to implement because of a lack of reliable and affordable methods for accurately measuring [waste] weight. Some companies have tried to solve this problem by using truck-mounted scales, which are expensive and hard to keep calibrated, or RFID tags, which can only give a binary reading if the container has been picked up or not and give the resident the option to skip their pickup day.

I've seen an interesting model gaining popularity in South America where a single multi-yard container [like a six-yard container] is given to a neighborhood or several square city blocks and residents all bring their trash to these shared containers. In this model, using Compology's dynamic routing technology would be highly advantageous because it would reduce the cost of service for residents and minimize truck traffic in residential neighborhoods.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/brittany_headshot_crop.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/brittany_headshot_crop.jpg)