Master Lock Has Had a Hold on the Industry for 100 Years

A century ago, Harry Soref made his Milwaukee-based company into a world leader with his invention of the laminated steel padlock

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/63/8b/638b6b51-92f7-48fa-999e-b6d1ad38739f/harry_soref.jpg)

A century ago, Harry Soref had an idea for a new product: a tough but affordable lock. The Russian, Yiddish-speaking Jewish immigrant approached family and friends in Milwaukee and asked if they would be willing to invest in his new business venture.

“Lox?” they asked. “Why would we want to put money in new lox? What’s wrong with the old lox?”

So goes the family lore, recalls Suzy Ettinger, whose late husband Alan was the grandson of one of the original investors. “They thought he was talking about the salmon served with bagels and cream cheese,” she says.

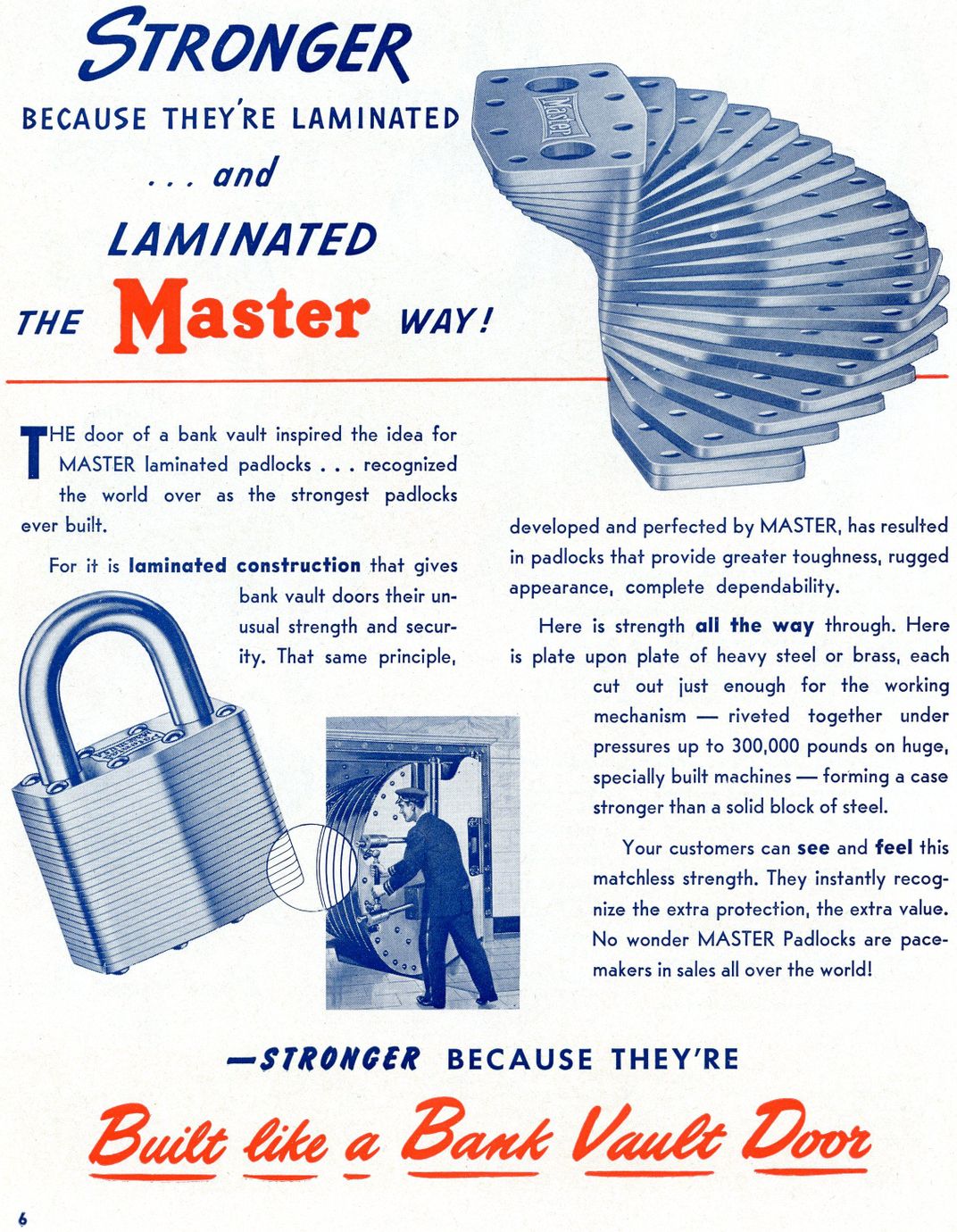

The business that the misunderstood entrepreneur founded is none other than Master Lock, which forever changed the security industry. Prior to 1921, locks were available in two styles: expensive but nearly impossible to break and cheap but easy to smash open. Top-of-the-line padlocks sold for more than $100 in today’s money; Soref’s invention cost about a tenth of that price.

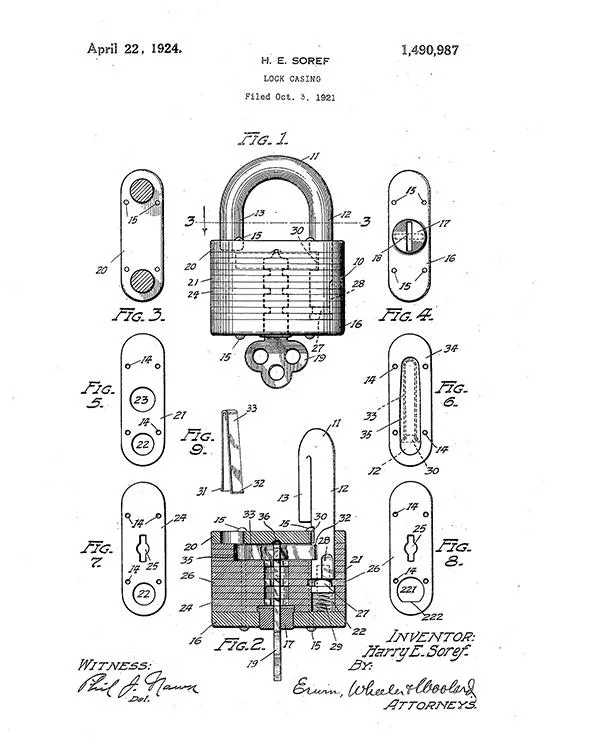

In 1924, Soref received a patent for a laminated steel padlock—essentially a series of metal plates fastened together to produce a durable yet inexpensive locking device that was difficult to break According to an early patent application, “the lock casing or body is substantially a metal block of considerable weight and inherent durability, which qualities enable it to successfully resist all ordinary attempts at its destruction. In other words, the lock casing or body is practically indestructible.”

That innovation changed the industry and set Master Lock up to become a world leader in padlocks, combination locks and other security products.

“Harry Soref was a traveling locksmith who got the idea for a high-quality, high-security lock that was also affordable,” says Justin Matuszek, director of marketing solutions at Master Lock, which is still headquartered in Milwaukee. “We still make versions of that original lock. They remain among our top sellers.”

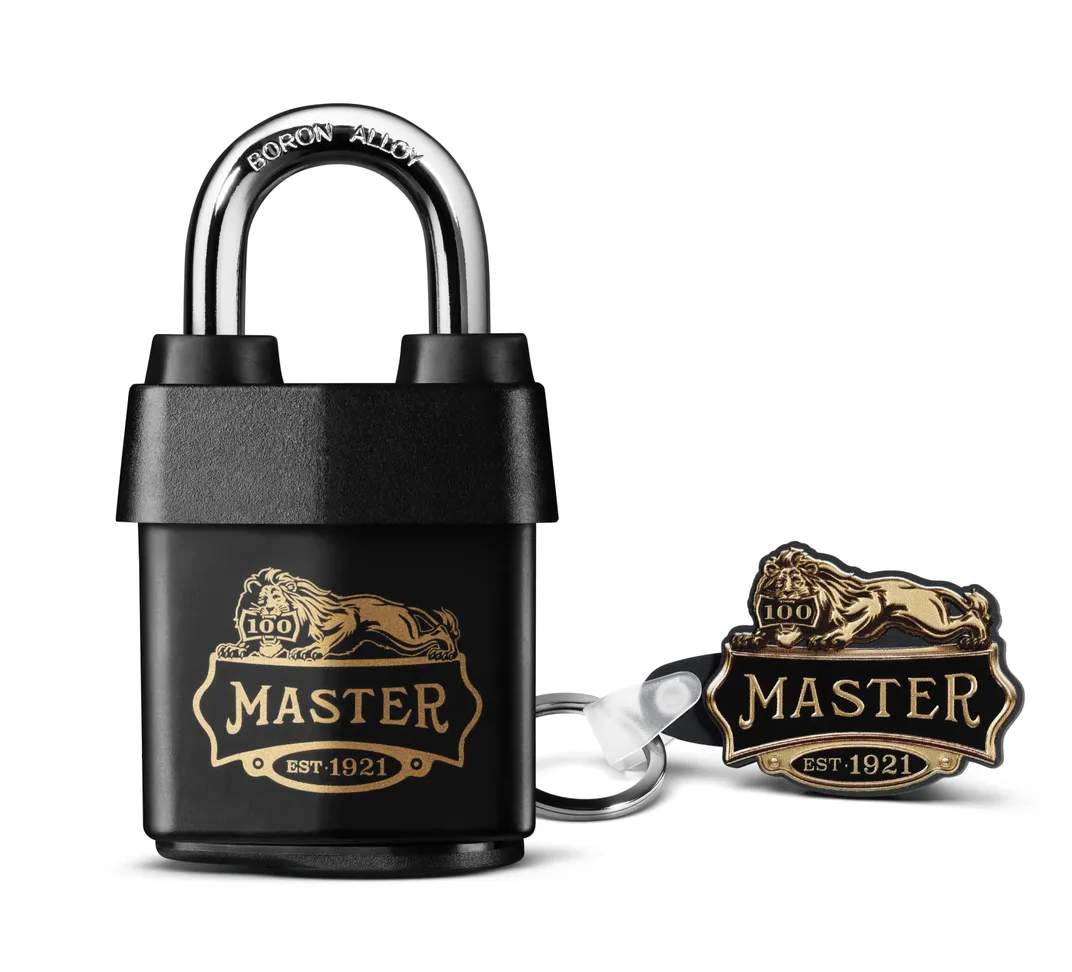

Throughout much of the 20th century, Master Lock positioned its premier product as “The strongest padlock ever built.” Early advertising reinforced this notion with images of lions, giants and powerful hands holding the locks. In 1974, the company ran a television commercial showing one of its locks surviving a high-powered blast from a rifle and still working. “Tough Under Fire” remains one of the highest-rated Super Bowl ads of all time.

Soref got the idea for his invention while working for the U.S. government producing locks to protect military equipment during World War I. He recognized the hardened steel used for armor on battleships, tanks and other vehicles was ideal for making the new kind of lock he envisioned.

The inventor began tinkering with scraps of metal and realized stamped-out pieces could be formed into an extremely tough padlock. Though some family members were confused by his initial proposal, a few farsighted friends—namely P. E. Yolles and Sam Stahl—saw the potential for the product and provided the necessary capital.

“The laminated steel lock today is essentially the same as Soref’s original lock in 1921,” says John Lupiezowiec, a Milwaukee collector of Master Lock memorabilia and knower of all things related to the company. “He stamped out all these pieces, riveted them together and then ground it down for a finished appearance. The assembled parts were so tough. It was ingenious.”

Master Lock grew steadily from its start in 1921. However, business boomed in 1928 when the federal government placed a $65,000 order for 147,600 padlocks to secure “the naughty nightclubs of Broadway”— as quoted from a wire service article in Master Lock News in 1967—during Prohibition.

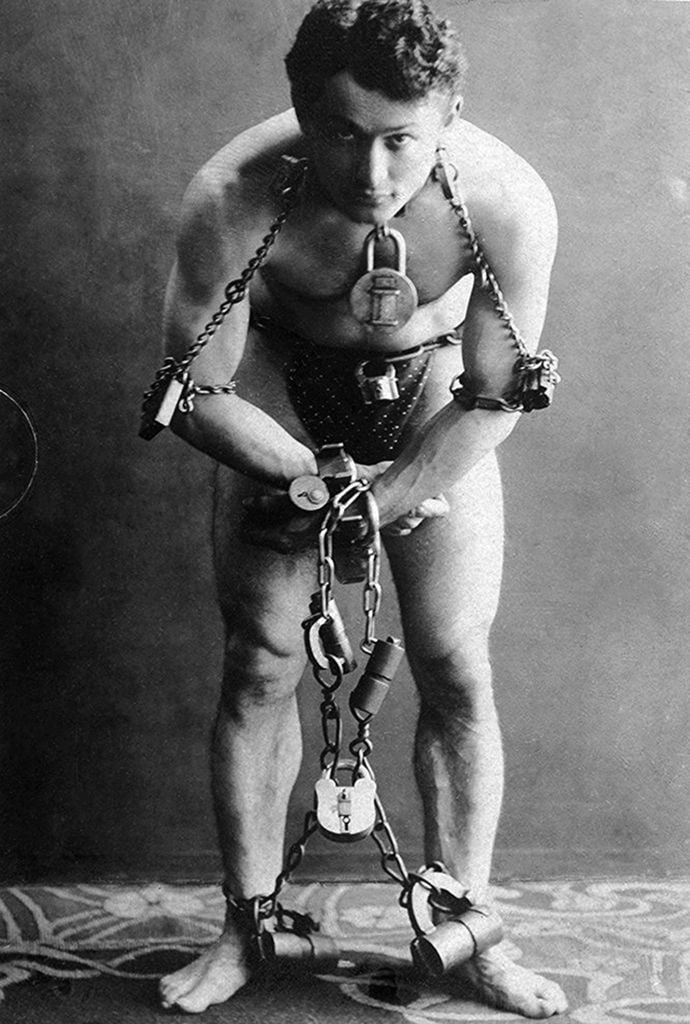

Soref also made Master Lock a household name through his friendship with Harry Houdini, the hugely popular magician of the early 20th century. Legend has it that the inventor taught the escape artist how to pick his product. Lupiezowiec doubts the veracity of that story.

“Soref and Houdini were friends in the circus before the war,” he says. “They were both locksmiths, and I think they shared trade secrets. Soref may have showed Houdini how to hide lock-picking tools on his body, but I’m sure Houdini already knew how to pick a Master Lock.”

The magician also knew his friend made a quality product. “Houdini used some of my work, and praised it highly,” Soref told the Omaha World Herald in 1931.

The company founder was very fond of his days in the circus, where he worked as an advance man promoting its arrival in town in the early 20th century before becoming a locksmith. Soref even incorporated some of that imagery into his new business. Various circus animals were featured on product packaging and in ads while a lion became the symbol for the company. It remains part of Master Lock’s corporate branding today.

While the laminated steel padlock blazed a path in the industry, Soref was also a trendsetter in employee relations and manufacturing processes. He valued his workers—who numbered around 600 at one time under his leadership—and insisted they call him by his first name.

“Soref would ask anyone in the organization if they had a good idea,” states Ellie Gettinger, education director at the Jewish Museum of Milwaukee, which includes artifacts of Master Lock and its founder. “He often asked employees on the manufacturing floor about improvements or new products that they thought would work.”

Perhaps because of his humble beginnings, Soref seemed to have a soft spot for workers in his production line. He made sure the same ornate bathrooms installed near the executive offices were also constructed on the factory floor. Soref refused to install time clocks and didn’t believe in quotas. He once cancelled a plan to install air conditioning in the building because it didn’t include the manufacturing space. “That’s where the money is made,” he reportedly said.

The inventor also put a lot of stock in his female workers. Soref believed they were more capable of maintaining their concentration on detailed handwork than men and willingly hired women to work on the production line. He even had the factory painted in pastel colors and provided other enhancements to favor females.

“He designed a unique assembly line for the women who worked for him,” Lupiezowiec says. “It was sort of a large ‘Lazy Susan’ device containing parts that moved around the workers so they didn’t have to keep getting up and walking to a bench for parts. Each woman on that line had a chair specifically fitted for her body—kind of an ergonomic design before it became popular.”

Soref died in 1957 at age 70, but his legacy lives on at Master Lock. His family and fellow investors eventually sold the business, which is still located in Milwaukee. The company continues to produce a variety of locks for numerous security applications, including electronic locks and even those that can be operated by a smartphone app.

Until his death, Soref remained an avid inventor. He constantly tinkered with ideas, receiving more than 80 patents for his designs and products, from a spare tire lock for automobiles and loading ramp for hand trucks to a hasp-and-lock system and even a display case for showing off his locks. However, it was the one invention that got away that may have propelled Soref to success with Master Lock.

As a young man, the Russian immigrant worked in a hardware store owned by his cousin Ben Urich. Soref developed a design to patch holes in tires using rubber bands. He intended to get it patented—except his cousin beat him to it first.

Soref was not happy with that outcome. When he invented the laminated steel padlock, he quickly filed the paperwork for a patent without assistance from anyone. Years later, Urich tried to apologize for his lapse in judgment, but Soref told him there was no need.

“You did me a favor,” he reportedly told his cousin. “I wouldn’t be where I am today if it wasn’t for what you did. Thank you.”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/dave.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/dave.png)