A New Material Could Make Medical Devices That Expand and Collapse

Harvard researchers develop a new origami-inspired material that changes shape

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/46/13/4613dcf3-67ed-43b1-8da8-f2219e8c1afa/img_3943.jpg)

Johannes Overvelde was pursuing a PhD in applied mathematics at Harvard University when he met Chuck Hoberman, designer of the Hoberman Sphere, a collapsible rainbow ball for kids. Both lived in Cambridge and had similar interests. Overvelde was working on developing transformable materials that could change stiffness, and Hoberman, an architect who also studies kinetic structures, had been thinking about how different materials could take on the properties of his sphere, changing form by articulating at different joints.

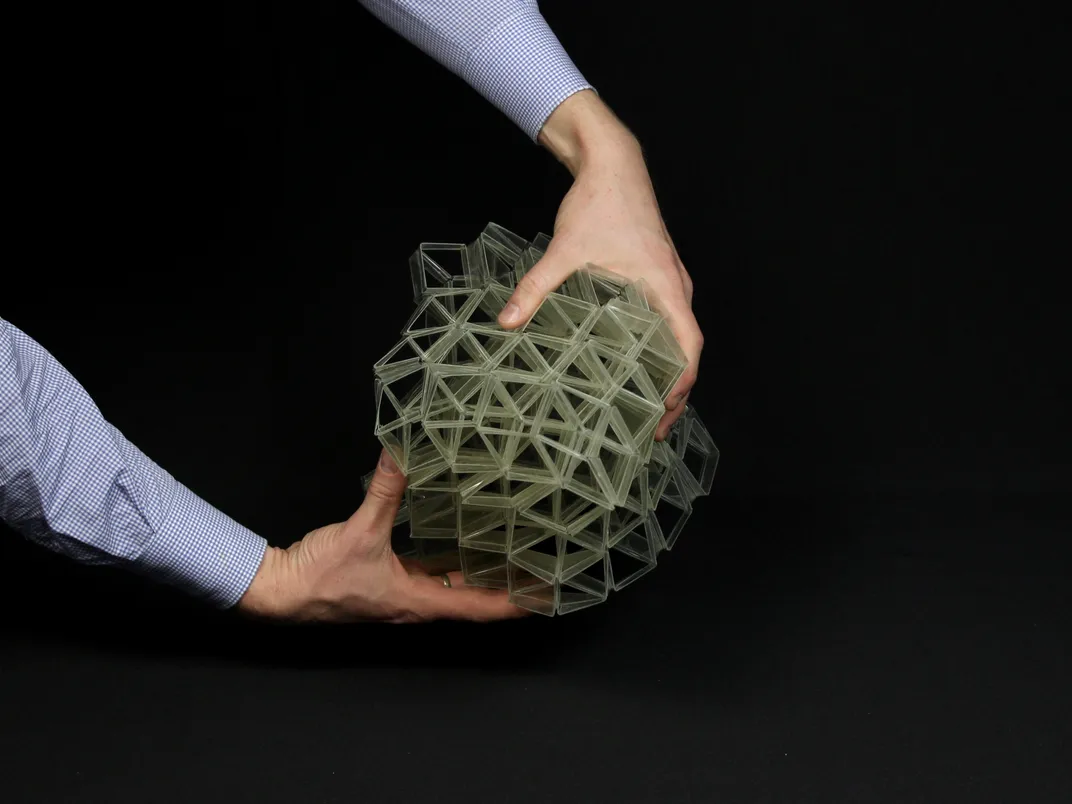

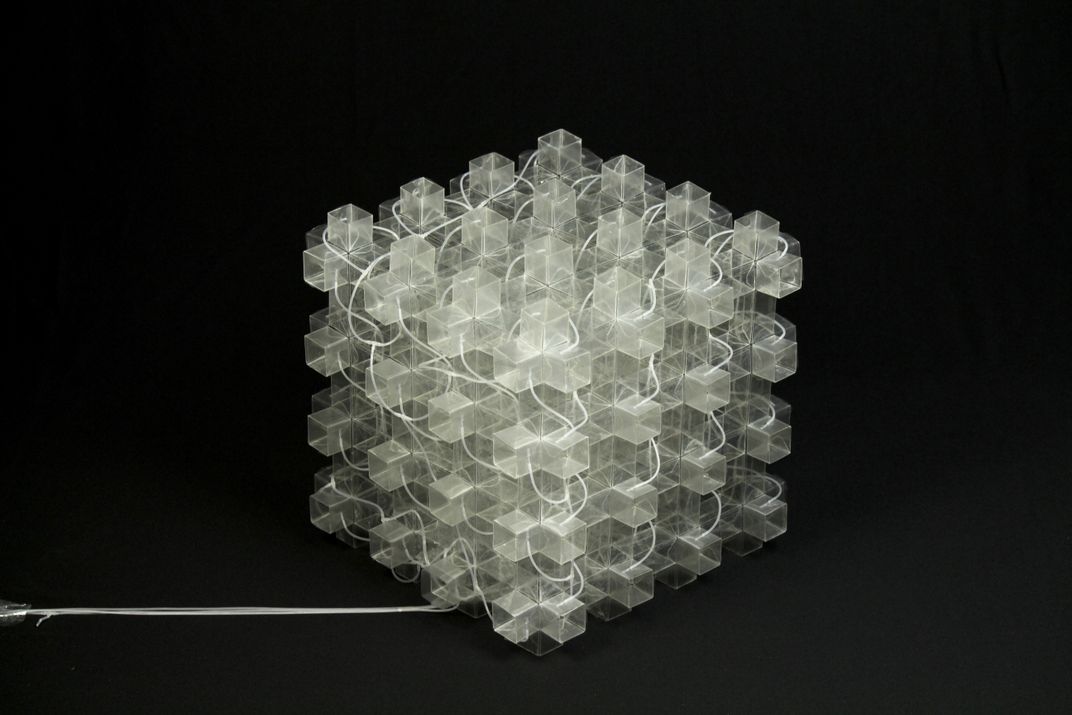

Borrowing bits from the Hoberman Sphere and the origami-based concept of snapology, where interlocking strips of paper snap together to create rigid structures, Overvelde and his team at Harvard have created what they call a metamaterial: an expandable structure that can be used on its own, or as a building block to create other structures. The attenuated cubes, which have three degrees of articulation, are made of thin polymer sheets that fold flat but can also pop up in a variety of different ways, just like the Hoberman Sphere. By attaching it to a pneumatic hose, a user can inflate a cube to create a bigger 3D structure. Overvelde says the material has numerous applications, from nano-scale stents that can be inserted into arteries and then expanded, to walls, which would fold open and ventilate your house when it gets hot.

“While snapology provides the geometric starting point for our research, our focus here is on the foldability of these structures and how this can lead to new designs for transformable metamaterials," Overvelde writes in a new paper, published in Nature Communications.

The researchers started with paper models, trying to prove that, with snapology, they could build something solid enough to use in architecture.

“We had a paper model that was glued together, but this was a lot of work, and the paper model broke after a week,” Overvelde says. “So we thought, ‘can we bring this more to an engineered structure?’ Using double-sided tape and laser cut thin plastic sheets—one thicker for faces, and one thinner for hinges—we made these units that could be deployed completely flat, but had specific degrees of freedom we hadn’t seen before.”

From there, the team experimented with different ways to change the shape of the structure. They decided that pneumatic activation, which was precise and easy to incorporate by running air hoses through the cubes, would let them use a structure in the most ways possible. The shape changes depending on which part of the structure is filled with air. “Any structure we make with this device will be reconfigurable,” he says.

For Overvelde, flexibility is the most important part of the concept. He likes to think of the cubes as a material, instead of just a structure unto themselves, because he thinks a lot of the value of the discovery comes from the many different ways they can be built.

The group's initial test cube was 50 centimeters square. But the idea is scalable—they have built a folding chair. Now, the researchers are experimenting with making the inflation mechanism sensitive to ambient cues, such as light or moisture. On a very small scale, the cubes can act like photonic crystals, reflecting back different wavelengths of light and different colors as they change shape.

“If you have a wing of a butterfly, the structure gives it color. So if you had a device that wants to change color, you could mimic that,” Overvelde says. “On the other side, you think about architectural application. If you made it responsive to heat, you could make a wall of this structure that opens up and breathes. You could make a structure that responds to water, so when it rains, it automatically closes up.”

Overvelde has proven that the concept works, and now he wants to see how it can be applied. In addition to photonic crystals and the moveable architecture, he thinks it could be used for everything from medical devices, that could be packed flat for easy insertion into the body, to robots and deployable spaceships.

“I’m really curious to see how other researchers will pick it up,” he says.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/DSC_0196_2.JPG)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/DSC_0196_2.JPG)