This Powerful Metal Glue Sets at Room Temperature

MesoGlue uses nanorod technology to fuse items together without heat, potentially replacing soldering

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/ab/45/ab45e56c-f315-4593-ada9-2da9d7fb64c3/42-77523058.jpg)

Almost all electronics in our lives—computers, stereos, toasters—contain printed circuit boards upon which different components are soldered. This soldering is often done by hand, an incredibly delicate procedure with little room for error.

But now, this soldering may be a thing of the past. A team of researchers at Boston’s Northeastern University have come up with a way to “glue” metal to metal at room temperature, no heat required.

Hanchen Huang, a professor and chair of Northeastern’s department of mechanical and industrial engineering, and two of his PhD students came up with the process, which they call MesoGlue. The team’s research was published this month in the journal Advanced Materials and Processes.

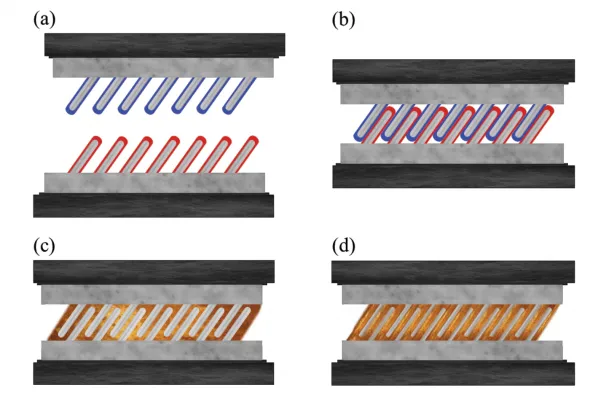

The process works by taking advantage of metallic nanorods—tiny metal rods just 10 or 20 nanometers wide, coated with iridium on one side and gallium on the other. The rods are arranged in lines on an upper and a lower substrate, like teeth on a zipper. When the teeth are interlaced, the iridium and gallium touch and become liquid. Then, the core of the metallic nanorods turns that liquid into a solid, creating a firm bond. The whole process takes less than a minute.

“It happens at room temperature, pretty much with just your fingertip pressure,” Huang says.

Unlike standard polymer glue, the metal glue stays strong at high temperatures and under high pressure. It’s also an excellent conductor of heat and electricity, and resists air and gas leaks.

MesoGlue can be used to attach components to circuit boards without soldering. This eliminates the risk of the soldering process damaging other elements on the circuit board, a longtime problem in circuit-board creation. MesoGlue could also be useful in heat sinks, the components that keep electronics from overheating. Typically heat sinks use what’s known as “thermal grease” or “thermal paste,” a conductive adhesive used to fill in gaps between the heat sink and the heat source. This is important because it keeps out air that would otherwise act as an insulator and reduce the heat sink’s performance. MesoGlue could replace traditional thermal grease, as it has a higher thermal conductivity and isn’t prone to drying out. Ultimately, the increased efficiency of heat dissipation could lengthen the life of the electronic product. MesoGlue could also come in handy for attaching pipe fittings in places where welding is not possible—underwater, say, or in outer space. Since no heat, electricity or gas is involved in making the bond, there’s no risk of explosions or other dangerous reactions.

Huang and his team have been working on the nanorod technology for a dozen years. Huang credits much of his success to the continuing support of the Department of Energy’s Office of Basic Energy Sciences (BES), which gave his lab long-term funding.

“In this country, we have only very few agencies that are supporting long term basic science and research,” he says. “[BES] is an agency that really makes a long-term investment, and that can really be impactful.”

Huang and his students have received a provisional patent for the MesoGlue process, and have launched a company to sell the product. They're currently in talks with various industries about possible uses. Huang sees MesoGlue being used in applications both everyday and extraordinary. Though the glue will likely be far too expensive for ordinary household use (no gallium-iridium-glued macaroni art for your fridge, sorry), the glue could easily replace soldering in ordinary household electronics—phones, computers, television—he says. It could also be used in military and aerospace technology, where electronics need to hold up under extreme force.

“The technology is ready, but it has to be integrated in the processes [of various applications],” Huang says. And that, he adds, could take a month, maybe a year. “I really don’t know," he says.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/matchar.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/matchar.png)