This Snap-On Sensor Could Tell Farmers Exactly How Much To Water Their Crops

A team at Penn State University is developing a clip-on leaf sensor that measures water stress on individual plants

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/d8/63/d8637750-e9cd-417a-956a-d51ee7d1d145/leafy3.jpg)

In 2010, scientists at California’s Pacific Institute, a global water think tank, defined a condition Earth could face called “peak water.” Loosely, it’s analogous to peak oil, but it’s not just that we’ll run out of water. Fresh water won’t vanish, but it will become still more unevenly distributed, increasingly expensive, and harder to access. Many parts of the world are facing water stress, and 80 percent of the fresh water that gets used around the world gets used for irrigating crops, according to the Pacific Institute’s president emeritus Peter Gleick.

Over the past 40 years or so, total water use in the United States began to level off. Part of that is due to greatly improved irrigation, and part of that is due to remote sensing technologies—satellites, radar and drones—that assess water stress in fields based on temperature or how much light the canopy reflected in different wavelengths. The better we can track hydration in plants, the more we can avoid both over- and under-watering our crops. But while these methods are suited well to broad views and can give an overall picture of the water fields are using, a team from Penn State University has been exploring a much more detailed method of measuring water stress, plant by plant.

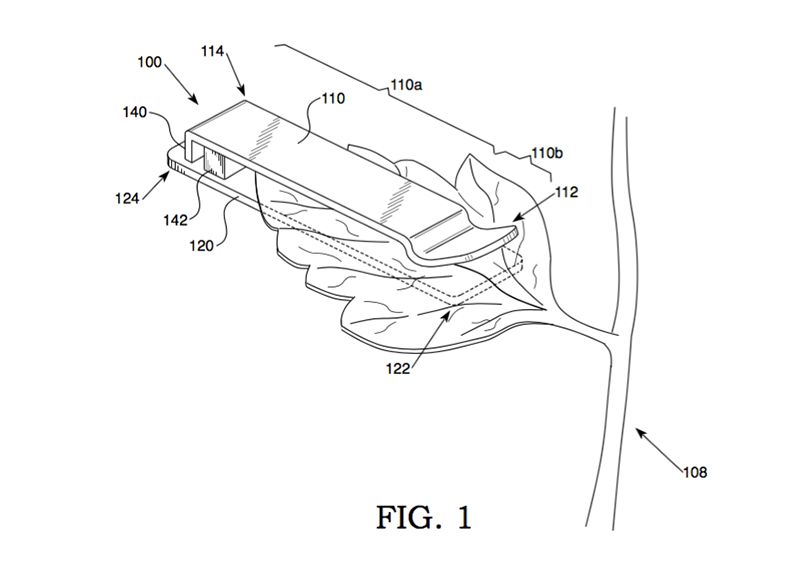

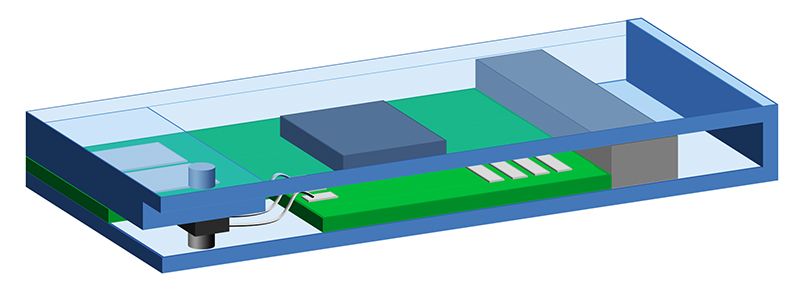

The system, for which the Penn State Research Foundation has applied for an international patent, features a clip-on unit that contains sensors to detect the thickness and electrical capacitance, or the ability to store a charge, of individual leaves. The array of sensors is connected to a WiFi node, which transmits the data to a central unit that tracks the measurements over time and uses them as indicators of water stress. Eventually, a smartphone app could run the whole system.

“Implementing such a technique in real practical applications, that’s hard because it needs to be light, reliable, nondestructive to the plant,” says Amin Afzal, lead author of the study, which was published in Transactions of the American Society of Agricultural and Biological Engineers. “What is presented in this article, it’s a kind of revolution for plant-based technique, and hopefully we can develop this technique and finally deliver it someday for practical applications.”

Current standards for measuring water stress fall primarily into evapotranspiration models and soil moisture sensing. The former involves calculating the amount of evaporation occurring on a field, and the later tests the soil itself, but in either case, the technique is measuring proxies for water stress rather than the stress the plants are under directly.

The Penn State sensor works a bit differently. A Hall effect sensor in the clip uses magnets to tell the distance from one side of the clip to the other; as the leaf dries out, the magnets get closer together. Meanwhile, a capacitance sensor measures the electrical charge in the leaf. Water conducts electricity differently than the leaf material, and the sensor can read that. A central unit in the field interprets the capacitance as water content and communicates it to the irrigation system. But tests also showed different capacitance during the day (versus at night) when the leaf was photosynthetically active.

Over the course of 11 days, Afzal and his colleagues allowed the experimental plant’s soil to dry out, measuring capacitance and thickness every five minutes. They noticed that both metrics maintained consistent behavior up until around day 9, when physical wilting was observable. Additionally, capacitance jumped up and down over the 24-hour light cycles, suggesting that capacitance can also detect photosynthesis.

In the field, only a selection of plants would need monitors. A larger field would need more total sensors, especially if it’s got a variety of elevations, soils or borders, but require fewer sensors per unit area. At an expected price point around $90 the units aren’t cheap, but they’re durable in the elements, designed to last more than five years, says Afzal.

The goal is to improve yield (or at least not diminish it) while reducing the necessary amount of water. Obviously, overwatering is wasteful. But underwatering can decrease yield, as water stressed plants produce less, thus making overall water efficiency go down. It’s not just about how much water you use, but how the plants use the water you give them, says Jose Chavez, an associate professor of civil and environmental engineering at Colorado State University who has studied evapotranspiration extensively, to better assess irrigation in Colorado.

“Depending on the crop, if it’s not deficit irrigation—applying less than the optimum—some staples may be very susceptible to losing a lot of yield,” says Chavez. “Technology that would detect ahead of time when it’s going to reach that level would prevent losing the yield by preparing the water manager ahead of time.”

The team from Penn State tested the device on six leaves of a single tomato plant—not a large sample size. Afzal, who is now a research data scientist at Monsanto, says that the technology is applicable to other plants, and at a larger scale, but will still require further studies to test different crops and conditions. He’s already put the sensor on rice plants, which have elastic leaves that stretch and shrink more with water.

“Other groups will need to pick it up and do evaluations, to see how it performs,” says Chavez. “If it shows it is reliable, in terms of working for different plants and soil types, to really pinpoint the level of stress, I think that would be nice. But how scalable is this to larger fields, and how consistent can you replicate these on different types of surfaces and environments? Those would be the key things for me.”