What If You Could Take a Vitamin 3D Printed to Meet Your Personal Nutrition Needs?

Fred Parietti, CEO and cofounder of Multiply Labs, wants personalized nutritional supplements to start a whole new movement

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/62/94/62942b55-8c9c-4a74-965a-6b6e4e23465f/multiply-labs-1.jpg)

When papers that Fred Parietti and his colleagues wrote started winning awards, he thought there might be something more to their idea. A robotics PhD student at MIT, Parietti had been working with a pharmacy PhD student, Alice Melocchi, on 3D printing pills with advanced delayed release schedules, and using robots to fill them. After graduation, Parietti, as CEO, and Melocchi, as CTO, joined tech accelerator Y Combinator, and in 2016 founded, with Tiffany Kuo and Joe Wilson, Multiply Labs, a nutritional supplement company with pharmaceutical aspirations.

The name Multiply Labs is an intentional reference to the vast number of possible combinations enabled by custom 3D printing supplement capsules. Currently, the company fills pills with 15 different supplements, each in amounts from 0 to 100 percent recommended daily allowance. I visited the company’s California office to talk with Parietti about the movement toward personalized health, the role of technology, the company’s coming launch (this spring) and future plans.

What’s the big idea? Why does the world need to customize our supplements?

Right now, every consumer needs to get a pill that’s identical to maybe 100,000, or a million other people. With a normal multivitamin, especially if you already have a healthy diet, you are taking more than what you need of many of these supplements, just to take the one that you don’t get from your diet. It’s also particularly evident for vegan and vegetarian people that need more of some supplements, but much less of others.

Also, people really hate to take many pills. That’s one of the leading causes of dropping out of supplement schedules. They always remember to take the after-breakfast one, but during the day they forget.

What’s the technology that’s made this possible?

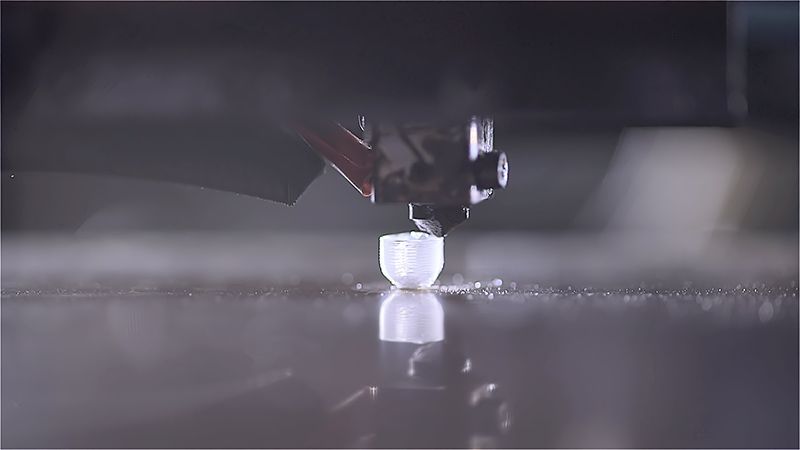

It would not be possible without robotics. One robotics part is the 3D printing. Inside the capsule we have different compartments, and in every compartment we put, in powder form, the supplement. We change the thickness of the compartment; a thin compartment will release first and a thicker will release last.

All the [3D printer] extruders on the market are not made to print ingestible stuff, they contain lead and they contain aluminum. So we custom built the extruder. And the other thing is the filament itself: We print using pharmaceutical polymers. This is stuff that is already FDA approved, made by pharma companies. But not even the pharma companies make the filament, so we need to buy the material from them, make our own filament, and use that to 3D print.

We also need a second robot that deposits inside every compartment the right amount of powder. That’s the part that’s absolutely impossible for a human—there’s no way to make these by hand. The second part is entirely new. It has between one and two dozen independent dispensing stations, and each one deposits just the right amount of powder inside every compartment of the pill.

Why all the attention to pharmaceutical grade equipment and materials?

The vision is really to become the interface for everything you need in pill form, not just supplements—also drugs. The FDA hasn’t come up with a framework for personalized medications, so if we try to start from drugs, the strictest interpretation of the current regulation is that every new custom pill is a drug, and needs a trial. We would need infinite clinical trials—not good. Supplements allow us to bring the same technology to the market much faster.

There are a lot of applications where doctors are already desperate for customization, like mental health, where there are just a few compounds, and the dosage varies. We’ve had clinical psychologists mailing us and they’re like, I have the same drug that goes from 25 to 800 milligrams. They would love to zero in with the patient on what they actually need. We can get the right effect without them having to take ten pills a day. Oncology is another field where you don’t want to give more, but you also don’t want to give less.

And the number of pills people take is almost linearly correlated with age. And of course, memory goes down, so it would be cool to have a single pill. Everything is built in—release times, dosages—and that’s it. It’s the same technology; it’s just we kind of have to start from supplements.

How do people choose what goes into their capsules?

If we know exactly what the customer needs, down to the milligram detail, that would be the best case for us, because we just feed that to the robot. But usually people don’t know that information about themselves in such detail. The fastest thing we could do was a sort of interactive process, where people specify their gender, their age, and their every parameter. We have some diet questions, and then we ask about goals, and then based on that we ask people for their priorities, like joints, for example.

The best way is going to be to have some sort of starter kit, where we include the blood test and a visit to the doctor. If we have the exact blood values, we will be able to tailor the pill to that. That’s going to take a little bit more time, because that’s medical information, but probably, I would say, towards the end of the summer we should be there.

This isn’t a cheap service. Who do you expect to be your primary customers?

Our pricing right now is more or less right in the middle of the premium range for supplements. [Pre-orders are $25 for two weeks of pills.] It’s mostly young professionals, grad students, business students, startup people and consultants. These are all people that [generally] are already really focused on their diet and fitness regime. It’s almost equally split between male and female.

Tell me a little bit about the larger movement toward customized nutrition. Why is it happening now?

We see a lot of trends, actually, in personalized nutrition. The kind of niche one is called biohacking, and then there is the mainstream one, wellness nutrition. In terms of biohacking, people optimize a combination of supplements called a stack. There are forums about it on the internet, where people actually experiment, and zero in their own mix of supplements. Sometimes when people experiment, they end up using substances that either don’t have enough scientific evidence, or don’t have the same health standards as a pharma company.

And then there is the wellness part. I think this is particularly common: As soon as you’re out of college, you start optimizing for health and longevity, and so you see this movement, like attention to diet and physical exercise. It’s not really just a thing for young professionals, but also mid-career professionals, they’re focused on longevity. That’s another very emerging trend, because these are people that are very successful, so their main problem is making sure that they can keep their high performance lifestyle for as long as possible.

Supplements are largely unregulated by the FDA. How do you ensure that the supplements you include are actually what they say they are, and how do you assess the effectiveness of the supplements?

We publish a lot of our results in the pharma conferences where the FDA goes, so we pretty much know we are under the lens. And they are looking at us because nobody believes we’re going to stop at supplements. So our answer is pretty simple: just to follow pharma standards. Even the machine is designed to have accuracy that is pharmaceutical grade, which we don’t really need for supplements, but it’s very important given our vision.

We don’t manufacture the supplement powder. We buy it, and then test it as it comes in and comes out of our facility, and then qualify the manufacturers.

Luckily, it’s not a mystery which supplements work, and why they work. The solution for us is that we are starting with only 15, and these are the ones with overwhelming scientific evidence. [Editor’s note: They are calcium, iron, selenium, zinc, vitamins A, B1, B2, B3, B6, B12, C, and D3, folic acid, caffeine and omega 3.]

What are some of your plans for the future of the company?

We’re also looking forward to collaboration with hospitals, because hospital pharmacies are already used for personalizing IVs. They don’t have the technology to personalize capsules, but doctors would love, especially for the intensive care patients, to change the pills every day. Pharma companies right now, I don’t think they are ready to use our technology for mass production, but they could use it for testing new drugs. If you have a new compound and you want to test the release, a machine like ours lets you do it in a day. You have your small batch ready with the release profile that you want to test.

Another very exciting area would be orphan drugs, for those illnesses that only a few people have. Right now it’s just not economically viable to develop drugs just for them, so in some cases they end up using some sort of cocktail of existing medications. If the problem is personalization, we’d love to just create a machine and just leave it there to produce drugs for the small group of people, because for us the machine is not very expensive, and if the molecule exists, for us it wouldn’t be even a loss. We don’t need to jumpstart a multimillion-dollar machine and make 100,000 pills. We can make ten, no problem.