What Will the Autonomous Ship of the Future Look Like?

Shipbuilding companies are experimenting with self-driving, remotely-operated and crewless vessels

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/47/73/4773c26c-bcf0-4d7b-9133-6982af687f47/rolls-royce-concept.jpg)

Sure as the self-driving car, robot ships are coming. Fleets of small wind-powered drones are circling the ocean, recording climate and current data. A Norwegian company plans to introduce autonomous ferries in 2018. And Rolls Royce and other shipbuilding companies are designing concepts and writing white papers that envision the future of autonomous ships.

The potential for these boats is high, and the potential uses varied. What will they look like? How different will they really be?

The answer is, it depends. Ships are already making use of navigation assistance, and will begin to be retrofit for more robotic control, similar to how carmakers have started with lane assist and automatic parking features. But when shipbuilders begin to build vessels specifically for autonomous use, a host of new features will become available or necessary, and others will vanish.

“We are not constrained by the same limitations that a manned vessel has,” says Oskar Levander, vice president of innovation at Rolls Royce Marine. “What you end up with is a very lean and efficient machine.”

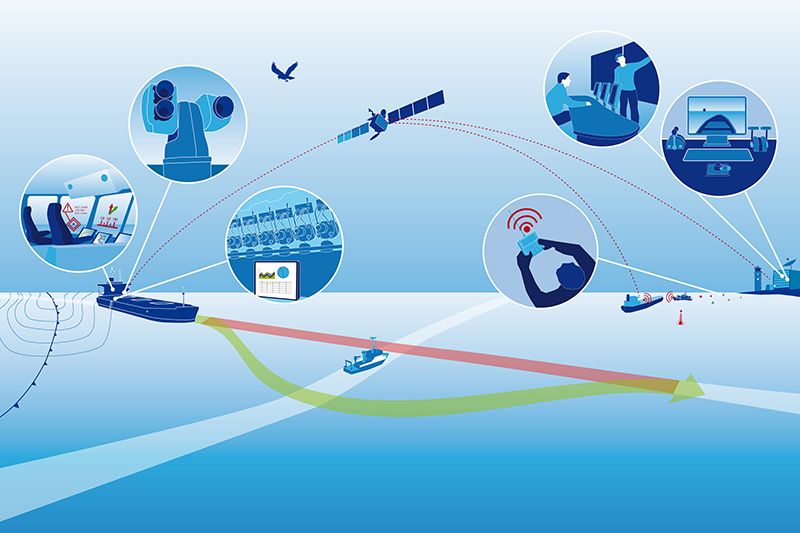

This is not an either/or situation. Aspects of three primary opportunities will get mixed and matched: autonomous control, or self driving; remote operation, similar to piloting a drone; and reduction or elimination of crews, which can even board or depart from the vessel.

One way that might look, says Levander, is a sort of hybrid. A ship on the open sea, traveling primarily straight ahead with little in its way, will be controlled by an onboard computer, with the occasional oversight of a land-based operator who may manage hundreds of different ships at once. As it comes to port, or enters a congested area, several things could happen. The remote operator could take full control, or a crew could boat out and board.

There are a number of obvious advantages to going crewless. Designs will eliminate the quarters, mess, stairs, doors, and just about everything else people use. One upshot of this is loads of extra space, available for more cargo. Another is a more streamlined exterior. It even enables the weight to balance out nicely. Traditional ships have a lot of weight in the stern, thanks to the bridge. The lighter center is buoyant, bending upward and requiring heavy ballast, often in the form of water, that is hauled around for no other purpose than to keep the ship level. Take away the superstructure, redistribute the weight, and it will reduce the ballast needed.

“It’s really only when you go fully unmanned that you can reduce all the systems,” says Levander. “When we add this all together, the reduced electrical consumption when we take out systems, the lower weight of the vessel, the lower wind resistance, we talk about a 10 to 15 percent fuel savings, for a typical cargo vessel.”

Elimination of HVAC, food and water, and other life-sustaining systems is another advantage, reducing cost of the ship while increasing space.

Much like self-driving cars, there isn’t a ready regulatory landscape. The Fraunhofer Center for Marine Logistics and Services is one entity exploring both the technological and legal aspects. In both ships and cars, it’s understood that the automation could provide great increases in safety—most maritime accidents are caused by operator error or fatigue, and a Fraunhofer-led report on Maritime Unmanned Navigation through Intelligence and Networks (MUNIN) expects autonomy to deliver a tenfold decrease in risk of foundering and collision. But regulatory bodies will require proof, with the added confusion wrought by shipping’s international nature.

The companies working on autonomous vessels are already discussing potential regulations, as well as the safety features that will be required, both internally and externally.

“Law governing unmanned vehicles in land, air and sea is still an evolving factor. It’s somewhat of a gray area as the various legislatures start their processes of legislation, and I guess sea is lagging behind,” says Richard Jenkins, founder and CEO of Saildrone, which sends a fleet of small autonomous water-borne vehicles around the world. Though large in reach—Saildrone has logged more than 70,000 miles so far—the company is starting small in terms of the vehicles. Jenkins likens these 23-foot boats to mobile buoys, which follow predetermined routes with the help of iridium satellites. The on-board computer transmits 2,000 parameters in real-time via those satellites, from various sensors including measurements like temperature and humidity, as well as the physical state of the vehicle including central processing unit [CPU] and battery status, and even navigational factors such as wind speed and angle.

That’s not all that different from what larger ships are doing. Where there once was a bridge, smaller towers with sensor banks mounted on them will acquire and relay information about the ships surroundings. Radar is the classic example, but LIDAR is already being incorporated. Where radar just provides dots on a screen, LIDAR can express surroundings in 3D. Infrared cameras, normal cameras and close-proximity radar will also be incorporated, and rather than sending each representation back to base, the computer will combine them into one rendering of the ship’s environment.

“To feed all these more advanced algorithms, and more advanced systems, you would need better data resolution,” says Wilko Bruhn, a research associate at Fraunhofer who worked on MUNIN. “Whereas you may only had one radar before, maybe you might have two, and of course, you will have more high-technology radars on the ship. It’s still the same sensor, it’s a radar, it works by the same general approach, but it will be much more high quality.”

Eliminating crew confers many advantages, but also necessitates some additional features in addition to the expanded sensors. Primarily, with no one around to fix anything, shipbuilders will have to construct for reliability and redundancy of systems, and operators will have to focus on predictive maintenance—even with small drones on board, most repairs will be impossible.

Instead of having one engine driving one propeller, ships will have two, or even four. According to Levander, diesel fuel will give way to liquefied natural gas. In fact, it already is—liquefied natural gas uses a simpler system, where pressure from the tank drives the gas through a series of valves to the engine, with no pumps or fuel injectors needed. Or, compartmentalized (and redundant) diesel engines will power batteries, which will run electric motors. Rolls Royce developed one design where the diesel generators are housed in shipping containers on the deck, so they’re easily removable for repairs or replacements.

“When you don’t have people on board you can really start addressing fire security in different ways. You can say, do I need oxygen in the engine room, or can I suppress that and make it very hard for something to go wrong?” says Levander.

A lot of this will be experimented with on short trips and smaller vessels first, where regulations are administered by a single government. Next, we’ll see bigger ships making long trips with dry cargo, which is the least destructive in case of incident.

“Do we have the technology that we would need for such a ship? Can we build it?” Bruhn says the MUNIN report was supposed to assess. “The technology has already been much more advanced than we expected … we are already closer to this autonomous ship than we thought at the beginning.”