Why Are Scientists Trying To Make Fake Shark Skin?

Faux marine animal skin could make swimmers faster, keep bathrooms clean and cloak underwater robots

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/1c/74/1c74dfe1-0cc3-42f1-bd17-c6c71efe7815/42-23594594edit.jpg)

From velcro to bullet trains, nature has inspired some of the most impressive feats of human innovation. This summer a crab-like, underwater robot, developed by Korean scientists, will search for ancient artifacts in the Yellow Sea. Drones are mimicking the flight movements of birds and bees. And, our biomimetic future looks bright.

A handful of researchers are now hot on the heels of a new creation: synthetic skin.

Marine animals use their skin to help navigate and survive their environment. Dolphins living in cold waters actually have thick skin to insulate their bodies and stay warm. Octopuses’ sucker-lined skin not only contains millions of nerves that help them sense and grasp prey, but it’s also embedded with unique color-changing cells that can render them invisible to predators. The skin bumps that line humpback whales' pectoral fins increase the animal's buoyancy. So, scientists see potential.

Using 3D printing and computer modeling technology, researchers are developing artificial-but-realistic marine animal skin for use in everything from anti-microbial door handles to underwater robots. George Lauder, an ichthyologist at Harvard University in Boston, and his team have developed the first true artificial shark skin with help from a top-end 3D printer.

Previous attempts involved rubber molds and fabric, and researchers struggled to manufacture material with both soft and hard components. Shark skin-inspired swimsuits made a splash at the 2008 Olympics, but Lauder’s research team actually found that the material in suits like Speedo’s Fastskin II doesn’t truly mimic shark skin or reduce drag, because it lacks denticles.

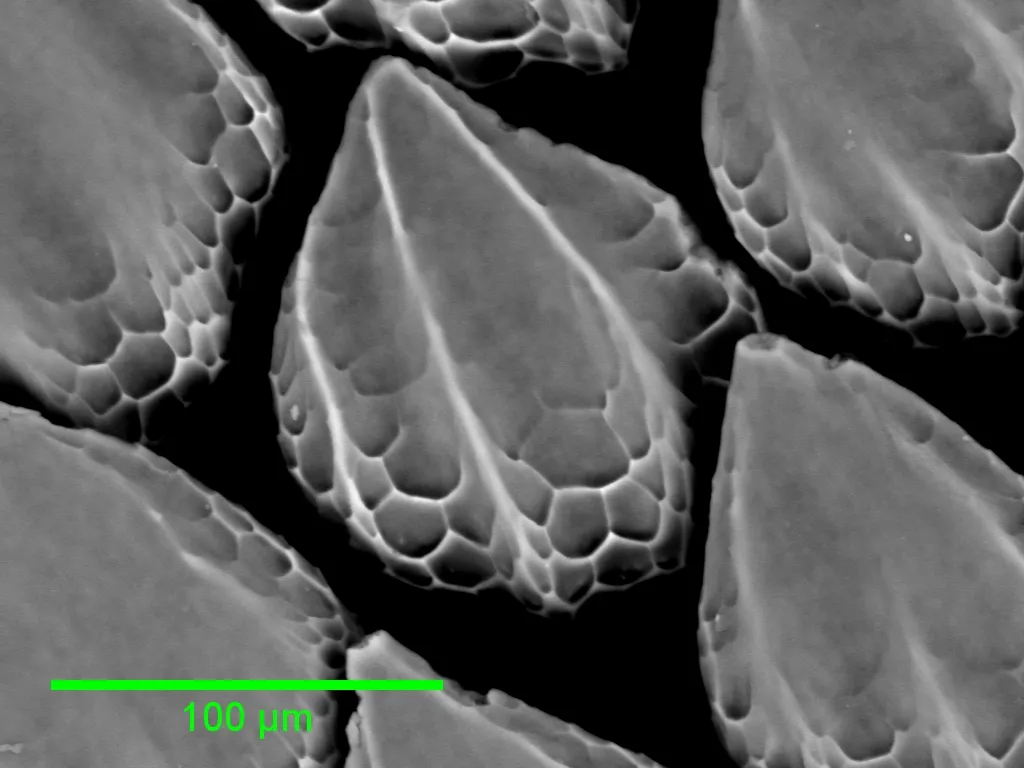

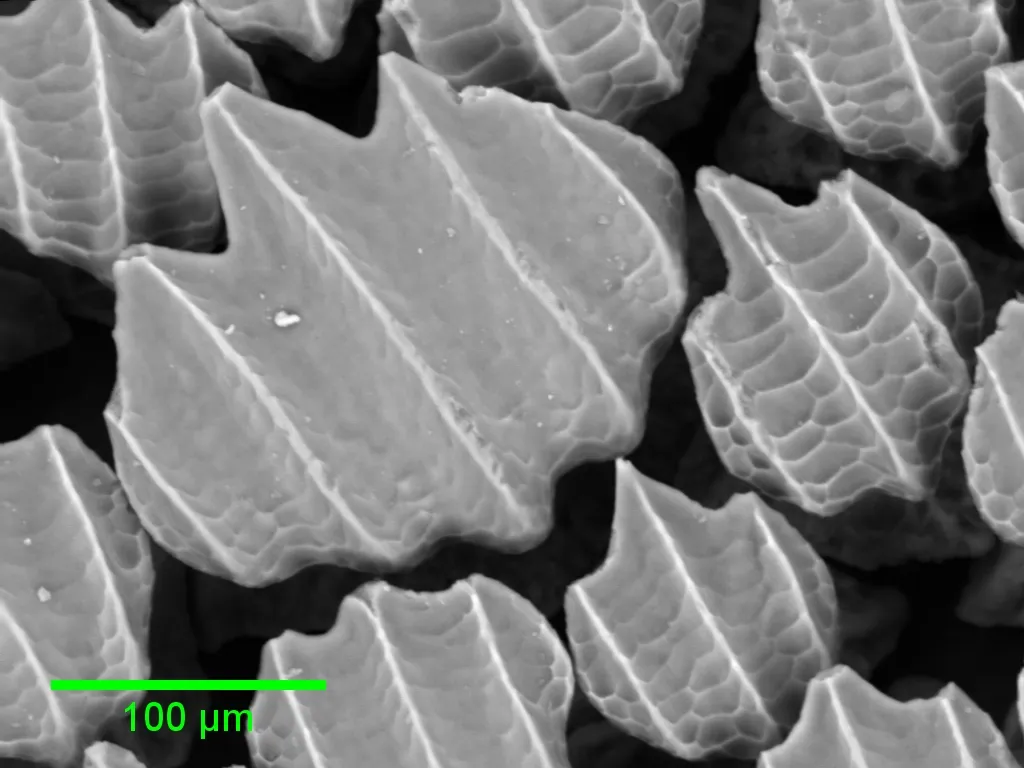

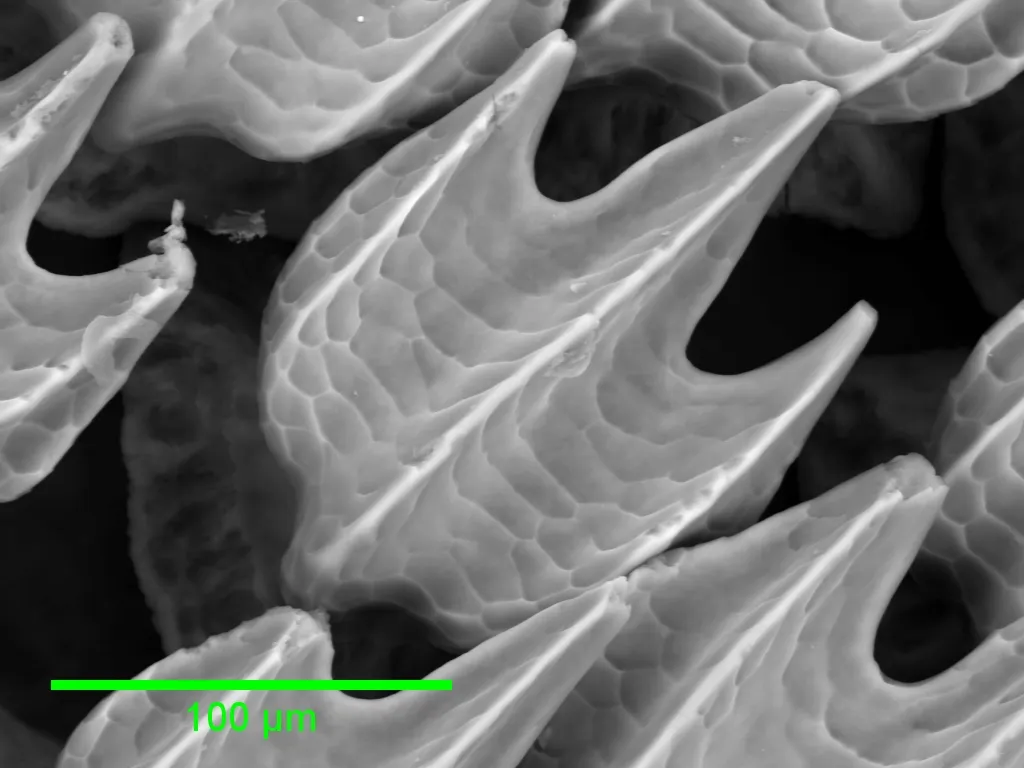

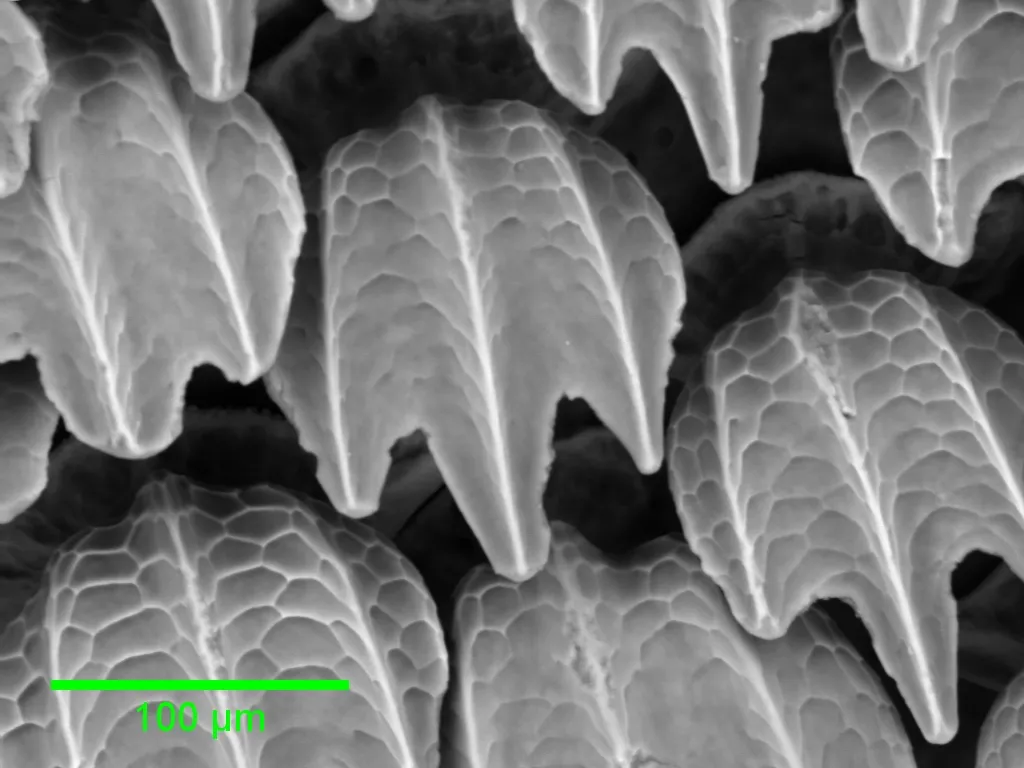

Sharks can swim at high speeds through ocean waters thanks to tiny, tooth-like denticles that cover their silky skin. “That turns out to be a very critical feature of performance of shark skin during swimming,” says Lauder. One would think smoother skin is better for speed. But, he adds, “It’s actually good to be rough, to have a rough surface of a certain kind when you want to move through a fluid environment, water or air, as efficiently as possible.”

Using a micro-CT scanner, Lauder's team scanned actual mako shark skin. From the scan, they created a 3D model and sent the model to a 3D printer, which made a plastic polymer material with a soft base covered in hard denticle-like structures. The end product has the sandpapery feel of shark skin. In a tank in their lab, the researchers tested the artificial skin and found that it increased speed by 6.6 percent and reduced energy expenditure by 5.9 percent in comparison to a smooth plastic fin without denticles.

“If you could make a swimsuit that had the structure of shark skin denticles or scales on a flexible surface that you could wear and was relatively like a full-body wetsuit, it would really enhance your swimming performance,” says Lauder. But, this new material isn’t quite ready for prime time. “It would be very, very challenging at the moment to incorporate this kind of structure into any kind of a fabric,” he adds. It’s a feat for the next decade.

A shark skin-like material might also serve as a line of defense against biofouling, or the accumulation of algae and barnacles on the bottom of ships. Most anti-fouling paint is toxic, so artificial shark skin could provide an environmentally friendly alternative. In 2005, researchers in Germany developed a silicone material, inspired by shark skin, that reduced barnacle settlement by 67 percent. Then, in 2008, engineer Anthony Brennan took a similar approach, creating a material called Sharklet that has a denticle-like texture and prevents 85 percent of normal algae adhesion on smooth surfaces. Sharklet has also been applied to medical devices and hospital surfaces. In hospitals and even public bathrooms, bacteria can spread from person to person easily, so coating these door knobs and equipment in a material that resists bacteria could reduce infections.

Researchers at Duke University in North Carolina also developed an anti-fouling material that twitches or wrinkles like animal skin (in this case, a horse twitching at the touch of a fly might be the best analogy) when stimulated. Another group at Imperial College London is trying to create a pipe material lined with microscopic bumps and chemicals that repel water—inspired by dolphin skin.

From a design perspective, shark skin could also be used to make airplane wings more energy efficient—an application Lauder sees proving useful in the future. Adding denticle-like structures to planes could reduce drag. Along similar lines, whale pectoral fins have already inspired helicopter wing designs.

Perhaps the most exciting use for these materials, however, lies in the developing field of bio-inspired underwater robots. “We’re going to have new kinds of underwater robots that have flexible bending bodies that move like a fish,” says Lauder. Several battery-powered fish robots are in the works, and logically, adding faux shark skin to them could increase speed and energy efficiency. Lauder and his team are collaborating with researchers at Drexel University in Philadelphia on a fish robot. They've since expanded their skin mechanics study to look across various fish species, as well, and see how different scale shapes and patterns affect swimming.

With 3D printing, scientists will be able to learn even more about how denticle or scale patterns on a fish impact swimming forces. “You can change the spacing [of denticles]; you can make them twice as spaced out. You can stagger them, make them overlapping, make them not overlapping, and make lots of changes to begin to actually tease apart the key features of shark skin,” says Lauder. These experiments will help scientists perfect artificial skins.

“This is a rapidly growing field at the moment,” says George Jeronimidis, an engineer at the University of Reading in the U.K. “We are just beginning to understand how integrated and functional the skin of marine creatures is.”

Jeronimidis’ lab has developed artificial octopus skin. Octopus skin has its own set of complexities: it’s soft, flexible and filled with millions of sensory neurons that help the organism navigate its environment. The engineer's synthetic version consists of nylon fibers embedded in silicone rubber, which keep the skin flexible but tear-resistant. It even has suckers, though these are passive—a real octopus can manipulate each sucker individually.

While there is still much work to be done, in the future, underwater robots could be endowed with the speed of a shark or the sensory intelligence of an octopus. And, with sophisticated artificial skin, they could venture where humans can’t—from navigating the murky waters of oil spills to searching for airplane wreckage to perhaps even exploring the ocean’s deepest depths.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Screen_Shot_2014-01-27_at_12.05.16_PM.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/Screen_Shot_2014-01-27_at_12.05.16_PM.png)