Building a Better World With Green Cement

With an eye on climate change, a British startup creates a new form of the ancient building material

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/Green-Cement-sample-blocks-631.jpg)

“You know, cement is everywhere,” Nikolaos Vlasopoulos, an environmental engineer at Imperial College in London, says while sitting in a brightly lit college conference room in a hulking seven-story building held up by the topic of conversation. “It’s all around us.”

Last year, the world produced 3.6 billion tons of cement—the mineral mixture that solidifies into concrete when added to water, sand and other materials—and that amount could increase by a billion tons by 2050. Globally, the only substance people use more of than concrete, in total volume, is water.

Cement’s virtues, Vlasopoulos says, have long been plain: It is inexpensive, pourable and, somewhat inexplicably, becomes hard as a rock. But one other important detail is seldom acknowledged: Cement is dirty. Not dirty as in it won’t come off your clothes—although that problem has dogged construction workers for centuries. The key ingredient is limestone, mostly calcium carbonate, the remains of shelled marine creatures. The recipe for making cement calls for heating the limestone, which requires fossil fuels. And when heated, limestone sends carbon dioxide gas wafting into the atmosphere, where it traps heat, contributing to global warming. Cement production is responsible for 5 percent of the world’s human-produced carbon dioxide emissions; in the United States, only fossil fuel consumption (for transportation, electricity, chemical manufacturing and other uses) and the iron and steel industry release more of the greenhouse gas. And with booming countries such as China and India using cement to construct their rise, cement’s dirtiness looms as one of the foremost downsides of globalization.

If cement’s enormous contribution to air pollution is largely overlooked by the general public, Vlasopoulos, 31, has been aware of it for some time. He grew up in Patras, a Greek port. His father was an engineer and his mother worked in a bank, and during Vlasopoulos’ summers home from Dimokrition Panepistimion Thrakis college, where he studied environmental engineering, he worked in a cement factory with his uncle. This was fortuitous. His job was to assemble the equipment that measured carbon dioxide emission levels. They were high; typically, a factory produces nearly a ton of carbon dioxide for every ton of cement. Vlasopoulos thought the work was interesting, but he didn’t see cement in his future. It was boring, it was old, it was dirty.

Then, one of his professors at Imperial College, where he was working on a master’s degree in engineering, received funding to examine a new type of cement made by an Australian company. The professor, Christopher Cheeseman, persuaded Vlasopoulos to collaborate on the project and earn a PhD. “This was a chance to do some nice work,” Vlasopoulos said in his typically understated manner.

People have been trying to build a better cement since just about the beginning of history. More than 2,000 years ago, the Romans devised a mixture of lime, volcanic ash and chunks of stone to form concrete, which was used to make harbors, monuments and buildings—the glue of early cities—including the Pantheon and the Colosseum. In the 1820s, in Leeds, England, about 200 miles from Imperial College, a stone mason named Joseph Aspdin invented modern cement. Aspdin heated a concoction of finely ground limestone and clay in his kitchen. After he added water, the mixture hardened. Voilà—the building block of the Industrial Revolution was born. Because the material looked like a popular building stone from the Isle of Portland, Aspdin called his invention Portland cement. The patent, issued in 1824, was for “an improvement in the mode of producing an artificial stone.”

The Australian developers had tried a new recipe, mixing Portland cement with magnesium oxide. They hoped to reduce carbon emissions because magnesium oxide can take the place of some of the limestone, and magnesium oxide does not have to be heated at such a high temperature. Limestone must be heated to 2,600 degrees Fahrenheit, but magnesium oxide can be prepared for cement at 1,300 degrees, a temperature that can be attained with biomass and other fuels that release less carbon, cutting down on fossil fuel consumption.

But Vlasopoulos quickly discovered that the blend did not reduce overall carbon dioxide emissions. In some tests, the emissions nearly doubled, because magnesium oxide itself is produced by heating magnesium carbonates, a process that releases carbon dioxide.

“I remember feeling very disappointed because when you see that the project you’re working on is not actually what you thought it was going to be, you lose motivation,” he said. “But we felt it was a very worthwhile project, a worthwhile idea, so we tried to find another way to solve the problem.”

At the time Vlasopoulos took up the question, in 2004, big cement firms around the world were looking for new ways to make Portland cement more environmentally palatable. The producers added steel byproducts, such as slag; coal residues, such as fly ash; and other materials, such as magnesium oxide, to bulk up the cement mixture, requiring less Portland cement. They experimented with mineral additives to reduce the temperatures needed to prepare the materials.

But it’s hard to modify a product whose chemistry is not well understood. “We have never actually known the exact chemistry of how this stuff gets hard,” said Hamlin Jennings, an expert on cement chemistry and head of MIT’s Concrete Sustainability Hub, one of several academic initiatives to forge “green” cement. “I don’t think there is any building material used in the world today that is more poorly understood than Portland cement.”

While the cement companies were tinkering with the original, Vlasopoulos took another tack. “You can only do so much to Portland cement to make it better,” he said. “It is what it is. It’s the material you start with. We had to come up with something else.” Vlasopoulos liked the idea of using magnesium oxide as a replacement for the limestone to form the cement, but it needed another material to make it hard. Mixing magnesium oxide alone with water wouldn’t do it—the mixture becomes slushy. And he needed to find a source of magnesium oxide that didn’t release so much carbon dioxide. The class of material he settled on was magnesium silicates, carbon-free compounds derived from talc, serpentine, olivine or other minerals. The world supply of these minerals is about 10,000 billion tons, an important factor because if one runs out of flour, no more cakes can be baked.

Vlasopoulos is not exactly keen to explain how his experimental compound works. His secret sauce is perhaps a very lucrative secret. Several patents have been filed. He will reveal this much: A few years ago, he began mixing magnesium oxide with other chemical compounds he created and water. The mixture hardened into a little ball. He brought it to Cheeseman’s office. “You could feel the heat coming off this little ball,” Cheeseman said. “Something was clearly happening.” Chemical reactions were firing; energy was being released. They did not get overly excited. “I mean, this is cement we are talking about here—it’s not exactly the sexiest stuff in the world,” Cheeseman said. “I wasn’t running up and down the halls doing cartwheels, but it was interesting.”

The chemicals Vlasopoulos mixes with magnesium oxide and water to make the cement harden are magnesium carbonates, which he makes by adding carbon dioxide to other raw materials. That means the cement, in some scenarios, is not just carbon neutral—it’s carbon negative. For every ton of Vlasopoulos’ cement produced, one-tenth of a ton of carbon dioxide could be absorbed.

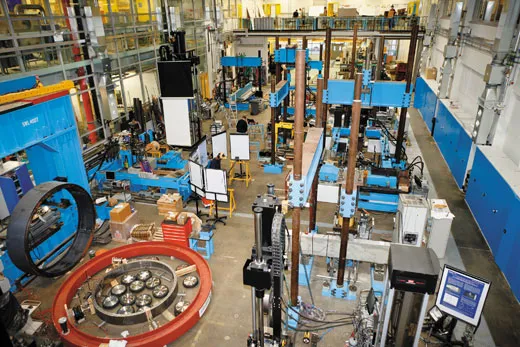

Eventually Vlasopoulos, with Cheeseman’s help, started a company, Novacem, to develop a new cement. The firm, with more than a dozen employees and partnerships with some of the biggest cement companies in the world, is located in a business incubator for high-tech startup companies at Imperial College. While some other companies in the facility are life sciences startups, with microbiology labs full of gene-sequencing machines and collections of test tubes, Novacem’s lab is a spacious plant that produces loud noises, loads of dust and bucket after bucket of cement. It is the first cement works in central London since the days of the Romans.

Workers wearing hard hats, protective glasses, masks and white lab coats operate a miniaturized version of a cement plant not unlike the one Vlasopoulos worked in during summer breaks.

Though still refining its procedures, Novacem is racing with at least five other companies and university centers to come up with a greener cement. “Given all the attention to carbon these days, a lot of entrepreneurs have popped up,” said MIT’s Jennings. “They see the opportunity side.” With cement a $170 billion-a-year industry, investment money is pouring in.

A California company called Calera has perhaps the most unusual approach: It harnesses carbon dioxide emitted from a power plant and mixes it with seawater or brine to create carbonates that are used to make cement. They can be added to Portland cement to replace some or all of the limestone. Calera is backed by a $50 million investment from Vinod Khosla, a computer engineer who is perhaps Silicon Valley’s most respected and deep-pocketed investor in green technologies. “We are actually making our cement out of CO2,” said company founder Brent Constantz. “We are taking CO2 that would have gone into the atmosphere and turning it into cement.” The technology is still in development, with a demonstration plant in Moss Landing, California, and a partnership with a Chinese group to build a plant next to a coal mine in Inner Mongolia, where they plan to use carbon dioxide emissions to make cement.

Calix, an Australian company, makes cement using superheated steam, which modifies the cement particles and makes them purer and more chemically reactive. The process also separates out carbon dioxide, making it easier to capture the gas and keep it out of the atmosphere.

Louisiana Tech University, like Novacem and Calera, is doing away with limestone altogether; it’s using a paste called geopolymer, which is made of fly ash, sodium hydroxide and potassium hydroxide.

“The dust will eventually settle and one of these ideas will work,” Jennings said.

Early on, one of Novacem’s biggest skeptics was the largest privately owned construction company in Britain, Laing O’Rourke. The executive in charge of keeping tabs on promising university work, Dheeraj Bhardwaj, heard about Novacem’s product through his scholarly connections. He looked at the chemistry, thought everything checked out and a few years ago took the idea to the chairman, who had plenty of doubts. There was no way the cement could be strong enough for commercial use, he said. It needed limestone. When Novacem’s material reached 40 megapascals—the bare minimum amount of strength needed for structural stability—then he might be interested.

Seven days later, a small chunk of Novacem cement placed in a vise-like instrument hit that mark. Twenty-eight days later, it hit 60 megapascals. Bhardwaj then took the results to the chairman, who said, “Let’s make this work.” Laing O’Rourke is now a major Novacem partner. Today, after much tinkering, the cement is approaching 80 megapascals. Concrete made with Novacem cement is comparable in strength to some standard concrete.

Novacem’s other partners include Lafarge, in Paris, the world’s biggest producer of building materials, and Rio Tinto, a London-based global mining company eager to help Novacem dig up magnesium silicates.

“The cement industry is now stepping up in financially significant, in scientifically significant ways right now,” said Jennings, referring to all of the various experimental approaches. “The world is changing. Everyone, including all the cement companies, will need to be as green as possible and take care of the world a little better.”

Jennings declined to endorse any particular new cement. “If Novacem’s works,” he said, “it’s a very attractive idea.”

Bhardwaj is more committal. He said he recently went to his engineering team. “Honestly, don’t be polite,” he told them. “Put aside any question about the carbon. Do you think this is something close to Portland cement?” The answer surprised him: They said it was better. Why? Not only was it strong, but it was pure white. Portland cement is slightly gray. “You could add colors to this cement,” Bhardwaj said. “Imagine having any color cement wall in your house that you wanted.”

The cement is a lovely shade of white, as Vlasopoulos pointed out while showing off his company’s prototype cement factory. Referring to the neighboring bioscience labs, he said, “We’re louder,” adding: “They are curing people in there; we are curing something else.” A hulking machine in front of him, idle at the moment, has long pipes that bang and clank, alarms that go off, and mixers that churn and spit out buckets of Vlasopoulos’ creation.

Vlasopoulos was in a peppy mood, having just proposed to his girlfriend the day before. (She said yes.) Over in a corner of the room was what he called “our museum.” On a small table were early chunks of Novacem cement—they looked like children’s blocks, just dustier. “This was not so good,” he said, holding up a fragile-looking one that was chipped. “Now we know what we are doing.” The plant can produce about five tons of cement per year. The company is also working on another facility that would produce 200 tons per year. If all goes well, the company intends to license its recipe to cement makers around the world.

The major obstacle that the company still has to overcome is history. Portland cement works. Always has, since that afternoon in 1824 in Joseph Aspdin’s kitchen. “Cement has been around a very long time,” Bhardwaj said. “People trust that. They can look around at all the buildings that have survived hundreds of years. So for Novacem, the proof of durability will take time. They will have to go slow. If I have to build a bridge or a building using Novacem cement, how do I convince people that that is OK? That’s the challenge. Nobody wants a bridge to fall down.”

Asked whether he would cross a bridge built with Novacem cement, Bhardwaj said, “I would have no problem with that.” But that bridge hasn’t been built yet.

Michael Rosenwald wrote about nanotechnology and flu hunters for Smithsonian. John Ritter lives in Pennsylvania.