Why This New Technology Inspired by Camel Fur Is Super Cool

A two-layered material that mimics the animals’ sweat glands and insulating fur chills surfaces 400 percent longer than traditional methods

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/49/38/4938f123-986a-478c-8402-4c538201ebc4/gettyimages-1150889841.jpg)

To survive life in the desert, a camel needs both sweat and fur. That’s according to engineer Jeffery Grossman of the Massachusetts Institute of Technology. “If it didn't have the fur, it would sweat way too quickly and run out of water, which is a really precious resource for the camel,” says Grossman. The engineer wondered if he could mimic the camel’s sweat glands and insulating fur by layering two materials. In new research appearing today in the journal Joule, Grossman details the new innovative technology that could be used to keep food and medical supplies chilled without requiring additional energy.

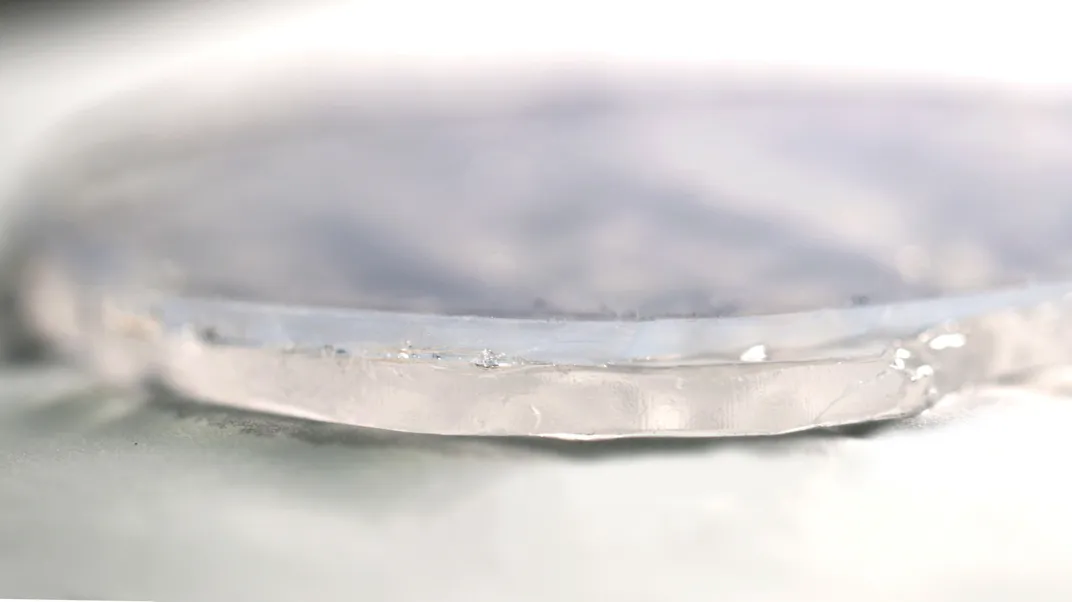

For the bottom layer of the camel-inspired system, Grossman used hydrogel, a highly absorbent network of polymers that is super-charged with water. As water evaporates from hydrogel, the liquid cools the surface it’s on. The top layer Grossman created was composed of aerogel, a hydrophobic silica structure filled with tiny pores that make the material more than 90 percent air—earning the substance the title of “the world’s lightest solid.” Aerogel acts like the camel’s fur, insulating the hydrogel from warmer ambient temperature and slowing water evaporation for sustained cooling power

Grossman knew that the layer atop the hydrogel had to be both insulating and porous so that water could evaporate through it. If the insulating layer was too thin, says Grossman, it’s like a “having a buzzcut on the camel” which would fail to insulate the hydrogel from surrounding heat. If the aerogel layer was too thick or not porous enough, the hydrogel’s water couldn’t evaporate, and the technology would lose its cooling power. “By designing the aerogel in just the right way, it would basically keep the water from evaporating too quickly, but not fully,” says Grossman. By slowing evaporation, “you get more out of each drop of water.”

To measure how the two-layer approach performed, Grossman and his team placed a heat sensor beneath the layers and placed the system in a humidity and temperature-controlled chamber. The sensor monitored the temperature beneath the hydrogel over time as liquid evaporated into the 86-degrees Fahrenheit chamber. The team compared their camel-inspired creation to a single layer of uncovered hydrogel. The two-layer system dropped the temperature near that of the hydrogel alone, but the duel layer kept that cooling power for much longer. Grossman found that the layered materials extended cooling time by 400 percent.

“I didn't think that we could get this close to the same cooling power and go this far,” says Grossman, describing the extended cooling period. “It's the kind of thing you get this in research and you're really happy because it just works so well.” Scientists have used hydrogel to cool surfaces before, says Grossman, “but what hasn't been done is to add another material on top of it that has a very specific use.”

While hydrogel and aerogel are not new, combining them in this way is, says Kyoo-Chul Kenneth Park, an engineer at Northwestern University who was not involved in the work. “I myself haven't thought about this kind of combining two materials—that's why I'm very excited to see this paper.” Like Grossman, Park looks to plants and animals to inspire his research. Because the creation is translucent, Park is optimistic that it could be used to insulate surfaces like windows.

Grossman thinks the technology could be applied to lots of areas that require passive cooling—meaning no external energy needs to power the process. Possible applications include insulating food storage, medical supplies and buildings.

Mary Ann Meador, an engineering professor at the University of Akron and former NASA scientist who was not involved with the work, says one barrier to implementing this kind of technology is the need to keep the hydrogel wet. Because hydrogel gets its power from water, once that water evaporates, the material no longer cools the surface it’s on. While camels can simply sweat to replenish moisture on their skin, to be useful, the gel needs to be regularly recharged with water—a problem Grossman and his team are working to solve. If this type of two-layered system could be revived with rainwater or condensation, for example, its cooling power could be endless.

The complex process used to make aerogel means it’s currently pricier than other forms of insulation on the market—$1 per cubic centimeter—though Grossman is optimistic that manufacturing techniques can bring costs down in the future. While hydrogel is squishy and flexibly, traditional silica aerogel is rigid and fragile. The firm top layer presents another hurdle in implementing this technology in products like clothing or building insulation, as the material easily crumbles, though Meador and others are creating flexible aerogels.

Next, Grossman is working on creating a third layer on top of the aerogel that acts as a switch to turn the system “on” and “off”. At certain temperatures, the third layer would permit evaporation, but at lower temperatures—when cooling isn’t needed—the switch would close, preventing unnecessary water loss.

Perhaps one reason that no one thought to combine hydrogel and aerogel before, says Park, is because this work combines two different areas of material science.

“Sometimes there we have some kinds of mental or physical barriers to overcome so that we can connect far different materials or systems. But these authors actually could overcome that barrier by getting their inspiration from nature,” says Park. “I think that's the beauty of bioinspired research.”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/corryn.png)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/corryn.png)