Scientists Invent Electronic Circuits That Dissolve in Water

The new type of temporary electronics could be implanted in the body or used to monitor the environment without a need for cleanup afterward

![]()

New “transient electronics” dissolve in the presence of water, opening up a new range of possible applications. Image via the Beckman Institute, University of Illinois and Tufts University

For most of us, an ideal electronic device is durable and long-lasting. An interdisciplinary team of researchers, though, has developed a new class of circuits that forces us to rethink our concept of what electronics can do in the world.

Their invention—an ultrathin, clear, silicon-based circuit that functions for a precise period of time, ranging from minutes to years, then dissolves completely in water—could lead to routine implantation of tiny electronics inside the body or in the environment without any need to extract them after use. The research team, from Tufts University, Northwestern University and the University of Illinois, reveals their advance in a paper published today in Science. They refer to it as an initial entry into a new field called “transient electronics.”

“These electronics are there when you need them, and after they’ve served their purpose they disappear,” said Yonggang Huang, who led the Northwestern portion of the team, which focused on theory, design and modeling. “This is a completely new concept.”

The circuits inside conventional electronics are made of silicon, a material that naturally dissolves in water over time but at rates that mean a typical circuit would take hundreds of years to disappear. The sheets of silicon that make up these new transient electronics, however, are just a few nanometers thick, so they can dissolve over the course of minutes when they come in contact with even a tiny volume of water or a body fluid. Watch how the circuit dissolves (almost like a breath-freshening strip) when it gets sprinkled with water, 15 seconds into this video:

So far, by printing circuits using soluble conductors (like magnesium or magnesium oxide) on the ultrathin silicon sheets, the researchers have created functional transistors, diodes, wireless power coils, temperature and strain sensors, photodetectors, solar cells, radio oscillators, antennas and even simple 64 pixel digital cameras that dissolve completely.

The research team imagines a range of different applications for their invention. Currently, surgeons are reluctant to implant medical monitoring devices (say, to check for an infection post-surgery) because of the difficulty of extracting them. But an implant made out of transient electronics that performed a diagnostic or monitoring function for a set period of time, then dissolved safely in the body, could become a routine way for a doctor to follow up on a patient’s progress after surgery. Other transient devices could monitor temperature or muscle activity, or deliver medicine internally.

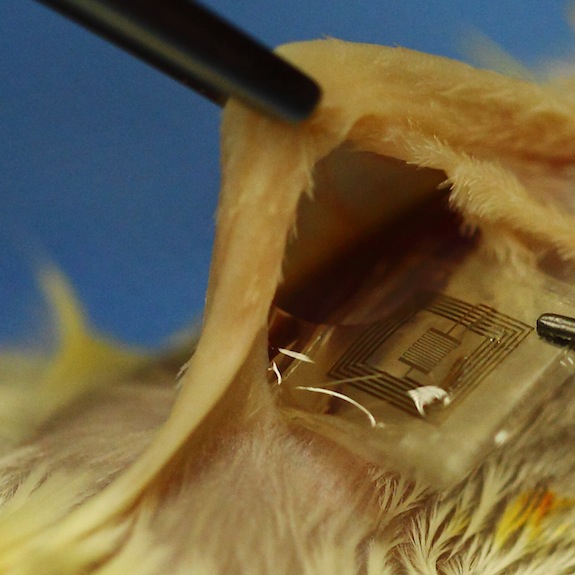

In rats, the team successfully demonstrated an implant that monitored for a bacterial infection at a surgical incision site and could eradicate it via heating if necessary. Three weeks after being implanted, only traces of the circuit remained in the rat’s skin.

The researchers implanted a transient circuit board into a rat’s skin to test the viability of using such technologies as post-surgery monitoring devices in humans. Image via the Beckman Institute, University of Illinois and Tufts University

Additionally, transient circuits could be used in environmental monitoring situations, such as using wireless sensors that are applied after an oil spill to track ground conditions before dissolving after a set period of time. Monitors could also be placed on buildings or roadways to detect gradual structural deformation over time. Transient circuits could even make their way into consumer electronics—a phone’s inner circuitry could perhaps be designed to dissolve in the presence of a particular liquid—to combat the increasing amount of electronic waste that’s produced as we frequently upgrade phones or other devices.

Because silicon is naturally abundant in the environment and the conducting material, magnesium, is biocompatible—and naturally occurs in the body—the researchers believe that the circuits will not harm our health or the environment when they dissolve. Of course, it remains to be seen whether this is the case, and further testing is necessary before the invention is implemented.

Transient circuits could be used in environmental monitoring applications, eliminating the need for cleanup afterward. Image via the Beckman Institute, University of Illinois and Tufts University

Each of these various applications would require different rates of decay. “A medical implant that is designed to deal with potential infections from surgical site incisions is only needed for a couple of weeks. But for a consumer electronic device, you’d want it to stick around at least for a year or two,” said John Rogers, who led the University of Illinois group that worked on experimentation and fabrication.

To control just how long a circuit sticks around, the researchers cover it with protective silk coats of different thicknesses. The thicker the silk, the longer it takes to dissolve, and only then does the silicon start to disintegrate. Until the silk is gone, the circuits can function while completely submerged in water or a phosphate buffered saline liquid, chemically similar to fluids in the human body.

The research group is currently refining their designs and conducting more animal tests, as well as working with a semiconductor manufacturer to test the potential for industrial-scale manufacturing. The fact that the technology relies upon printing circuits on a silicon surface—like the vast majority of electronics in existence—means that minor alterations to the manufacturing process could yield functional transient circuits.

“It’s a new concept, so there are lots of opportunities, many of which we probably have not even identified yet,” Rogers said. “We’re very excited. These findings open up entirely new areas of application.”

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/joseph-stromberg-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/joseph-stromberg-240.jpg)