Scanning a Stradivarius

Medical 3-D imaging makes it possible to study the world’s greatest stringed instruments – and uncover the secrets of its makers

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/ATM-Stradivarius-Bruno-Frohlich-CT-scan-631.jpg)

As an 8-year-old boy in Denmark, Bruno Frohlich wanted to be a musician. He became a church organist’s assistant, yearning to create the haunting sound that poured from the instrument’s pipes.

But Frohlich soon became more interested in how the organ worked; the church organist arrived one morning to find his young pupil taking apart the instrument with a screwdriver and a hammer.

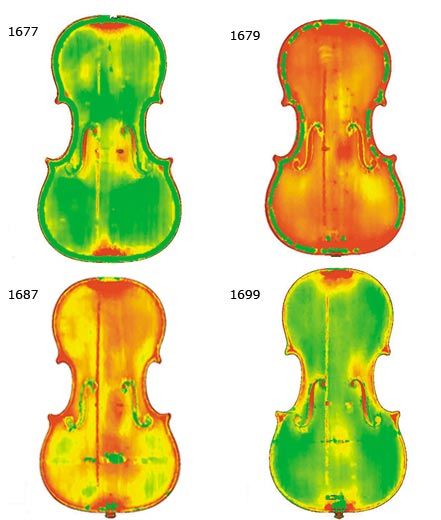

Frohlich, 64, and now a research anthropologist at the National Museum of Natural History, is still fascinated with musical instruments—though he has found a less destructive way to study them. In his laboratory sits a massive CT scanner, which is normally used to create three-dimensional images of human tissue. Frohlich uses it to probe the anatomy of the world’s greatest violins, including those made by Antonio Stradivari between 1677 and 1727.

Musicians throughout Europe traveled to Italy to purchase Stradivari’s violins. His competitors tried to figure out his “secret”—or, failing that, simply put his name on their violins. Today, artisans and scientists are still struggling to recreate the Stradivari sound. Some have chipped varnish off the violins, hoping to discover a special chemical compound. Others have built their own instruments, using artificially aged wood.

But Frohlich puts no stock in secret ingredients. He prefers an investigation into all elements of the violins’ design. “There’s no way we can do a study focusing on just one small thing,” he says.

Nor does he see much value in trying to assess how a violin actually sounds—mainly because there is no objective way to measure euphony, where beauty is in the ear of the beholder. Still, the popularity of Stradivari’s instruments attests to their having struck a chord among many musicians.

Over the past ten years, Frohlich has scanned nearly 50 violins and other stringed instruments—by Stradivari, his contemporaries and current artisans. He is still compiling data, but has come to some initial conclusions. One distinguishing characteristic of a Stradivari violin is a consistent volume of air within it, which can affect tone quality. And, while the wood in other violins can be several millimeters thick, many of the Stradivari instruments Frohlich has studied are just one millimeter thick in places of the body. Frohlich is not certain whether the thinner wood contributes to the instrument’s unique sound. More likely, he suggests, musicians simply preferred a violin that weighed less—allowing for more comfort with the instrument and better performances.

Until now, there has been no way for instrument makers to quantify such characteristics and correlate them to musicians’ preferences for dark, low tones that linger in the air and for richness and depth of sound.

“What we might find from Frohlich’s work is that there’s a way to describe a perfect air volume before you hear it, before we finish the violin,” says John Montgomery, a violin maker who repairs instruments at Smithsonian museums and the Library of Congress. Such knowledge, he adds, “can be repeated from one instrument to the next.”

Once Frohlich is done analyzing the data, he says, he’ll work with Montgomery to make the results available to instrument makers—something unthinkable in Stradivari’s day.

“In the old days you had this very rigid master-apprentice relationship, and it was very secretive,” Montgomery says. “You weren’t allowed to tell people what you knew, you had to keep it to your trade.” But Frohlich’s research could transform the crafting of violins from solo performances into symphonies.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/erica-hendry-240.jpg)

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/accounts/headshot/erica-hendry-240.jpg)