What happens when you combine the strength of the American worker with investment in cutting-edge science and technology? Innovations capable of changing the world.

Manufacturing USA®, a network of 14 manufacturing institutes across the United States, does just that. Each of its public-private partnerships enables precompetitive collaboration between industry, academics, government labs and manufacturing institutes to support research and workforce development and usher in the next generation of manufacturing across energy, health, medicine and technology.

From clothing that can adapt to temperature to bandages that can speed up the healing process, here are five innovations developed by Manufacturing USA-affiliated institutes that will soon change the lives of people across the country.

1) Fabrics: The New Software

Imagine athletic garments that could self-adjust to increase performance and breathability, or military uniforms that could adapt to changing climates and regulate temperature. Our clothes help define us, yet the fabrics we wear haven’t evolved much over the course of human history—that is, until now. Recent breakthroughs in fiber material and fabric processing are allowing engineers and manufacturers to design and produce fibers and fabrics that see, hear, sense, communicate, store and convert energy, regulate temperature, monitor health and change color. The basis for these new fabric capabilities are fibers that contain semiconductor devices, made possible by Advanced Functional Fabrics of America (AFFOA). By transforming traditional fibers, yarns and fabrics into highly sophisticated, integrated and networked devices and systems, AFFOA has enabled a domestic, manufacturing-based revolution and set the stage for a "Moore's Law for fibers," meaning that the functions of fibers will develop exponentially over time. Since its inception, AFFOA has successfully integrated hundreds of thousands of electronic chips into fibers. The institute is now scaling the technology and making it available to the more than 130 startups, universities, domestic manufacturers and commercial brand companies that make up their Advanced Fabric Innovation Network. These initiatives and more will support new waves of product development in the years to come and fundamentally shift our relationship with clothing.

2) Better Automotive Brakes

While military vehicles are built for endurance, rollovers are still a common issue faced by our troops. To increase soldier safety, Lightweight Innovations for Tomorrow (LIFT) and Ricardo Defense LLC developed an improved anti-lock brake system (ABS) that can be installed in future vehicles and retrofitted to current Humvees. According to data from the National Highway Traffic Safety Administration on vehicles similar to those used in the military, this technology could improve rollovers by as much 74 percent. Beyond technological improvements, the project trained soldiers on how to install the new brake system and demonstrated its effectiveness in the field. Long-term, it could lead to increased commercial availability of improved ABS systems.

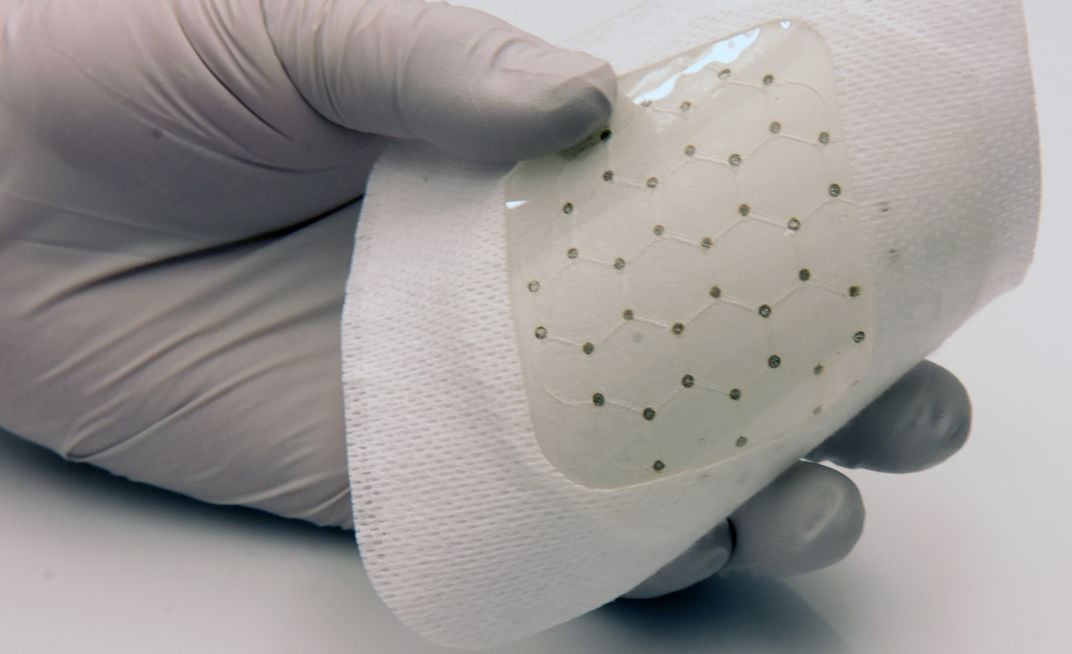

3) Smart Bandages

Over 6.5 million Americans suffer each year from chronic non-healing wounds, and treatment costs related to these injuries add up to over $25 million annually. To combat this, America’s Flexible Hybrid Electronics Manufacturing Institute, also known as NextFlex, is developing a bandage that can not only sense, but also control oxygen flow to wounds in order to speed healing. Purdue University, Indiana University and Western Michigan University have joined forces to manufacture a prototype using flexible semiconductor units, which is now in its testing stages. Ultrathin and comfortable, this bandage could increase the collective health of the American population.

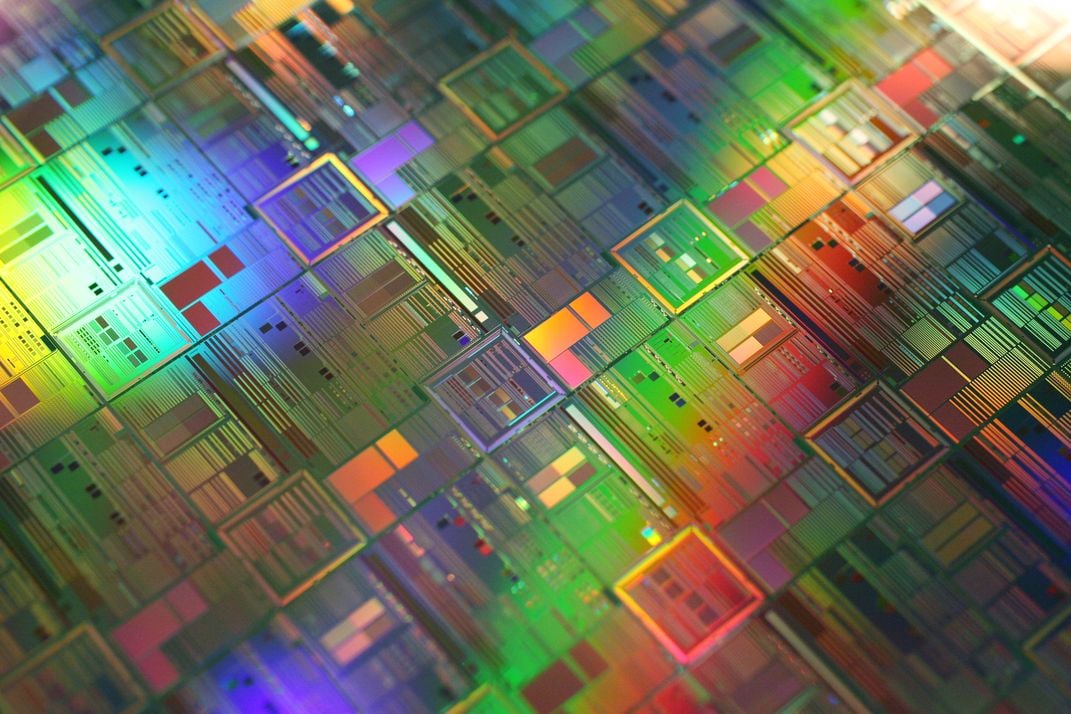

4) Light-Speed Computers

Photonic chips, which operate using light as opposed to electricity, promise to change computing as we know it. With this new technology, computers and other electronic devices could operate millions of times faster than they do now. One challenge that still needs to be unlocked is how to produce photonic chips at scale in a cost-effective way. Thanks to the American Institute for Manufacturing Integrated Photonics, widespread use is on the horizon. Columbia University and Cisco Systems are currently developing a critical fiber-to-photonic-chip coupling technology that will open the path to high-volume manufacturing and reduce cost by downsizing system components. Access to this previously unheard-of computing power will open the door for all types of product development initiatives, accelerating the technology-driven age we live in.

5) Accessible EV Charging Stations

Electric vehicle (EV) charger models in use today face certain limitations, among them restrictive building permits. Enter a new generation of EV charging stations, spearheaded by PowerAmerica and North Carolina State University. Thanks to wide-bandgap semiconductor technology, these new charging stations will be 10 times smaller (about the size of a small microwave), 60 percent more efficient and able to charge cars more quickly than existing models. What's more, PowerAmerica is working with a number of startups to scale the chargers' commercial availability, which could make electric vehicles accessible to more people.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/05/40/0540a325-25ac-44c1-95ed-cbc208a7082b/manufacturing_usa_banner.jpg)