What Makes Salt Water Taffy the Perfect Summer Candy?

The first families of the sugary treat stir up another season of making history by the bite

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/a3/09/a30913a4-3091-44c7-917c-f4d74ddbb170/julaug2017_g83_prologue.jpg)

Not all candy is pulled, but much of it is,” Justice William Howard Taft wrote in the 1921 Supreme Court decision Hildreth v. Mastoras. That high-profile patent dispute over rival improvements to salt water taffy pullers—the multiarmed machines that aerate the candy and give it its signature chew—shows just how lucrative salt water taffy had become since it appeared on the boardwalk at Atlantic City, New Jersey, in about 1880.

Taffy, unlike chocolate, resists melting, so it was the perfect hot weather confection for the country’s new, and booming, seaside resorts in the days before refrigeration. “Until the beginning of this century, candy was pulled only by hand,” explained Taft, the former U.S. president. “Since 1900, the art has advanced from a production of 300 pounds a day to 10,000 pounds, with the same labor.”

Today a single taffymaker can crank out five times that amount annually, and over the last century the gooey treat has become synonymous with the carefree days of summer. At antique taffy stands up and down and even between the coasts, vacationers line up for a taste of American tradition. “The pullers in the window have been in use since the 1930s, and pull taffy every day,” says Mark Igel, co-owner of The Taffy Shop in Estes Park, Colorado. “It’s like a museum that makes really good candy.”

Many stands are still run by descendants of founders—or those otherwise fated to enter the trade. “When I was 12, my family took a trip up the Oregon coast,” says Daniel Shirk, who co-owns Ainslee’s Salt Water Taffy in Depoe Bay, Oregon. “I have a very distinct memory of watching my [future] father-in-law making taffy through the window of this store.” In 1915, after Herbert Haven pursued his wife-to-be from Boston to Portland, Maine, his parents, candymakers themselves, made a wedding present of the family taffy recipe. Haven’s Candies uses it to this day.

We tapped a few long-pedigreed taffymakers to share the lessons and lore of this deeply American tradition.

Anna Bushnell

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/1a/3c/1a3c7d00-56ed-4091-a2b1-47ae8572f681/julaug2017_g28_prologue.jpg)

President and Co-Owner

Dolle’s • Ocean City, MD

Founded 1910

Top flavors: Peanut Butter-Filled Vanilla, Chocolate, Banana

It’s hard to say how much we sell every day, as we only make it on demand, so it fluctuates drastically. But in the busiest days in the summer, we sell upward of 1,500 pounds. It’s primarily corn syrup, sugar and then palm kernel oil. That’s really it. We use approximately 120,000 pounds of sugar a year and 225,000 pounds of corn syrup. It is temperamental, though. It has to be cooked according to the temperature and humidity. Let’s say we have a heat wave and it’s over 100 degrees outside for a week. We’ll actually make the candy harder. We cook it up a degree or two hotter, so it won’t melt.

Art Dillon

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/21/c3/21c3533a-e316-4580-a0f9-5f8bedf41c82/julaug2017_g25_prologue.jpg)

Master candymaker

Haven’s Candies • Portland, ME

Founded 1915

Top flavors: Peanut Butter, Sea Salt Caramel, Watermelon, Beach Ball, Blueberry

We get approached every once in a while for unique flavors and we’re pretty accommodating. Up in Lisbon, Maine, every year they have a Moxie Day parade. Are you familiar with Moxie Cola? I’d equate to it Dr Pepper. The parade organizers approached us to make Moxie taffy. We did a pretty good job of it. In the ’90s, when internet cafés were popping up everywhere, one place wanted coffee flavor with added caffeine, which was so pure it was dangerous to handle. A local lobster festival asked if we could make a lobster flavor. It didn’t get as far as a taste test, thank goodness.

Daniel Shirk

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/28/6a/286ad058-f8e3-4c1d-befa-9d946cc6ff7a/julaug2017_g29_prologue.jpg)

Co-Owner

Ainslee’s Salt Water Taffy

Depoe Bay, OR

Founded 1947

Top flavors: Peanut Butter, Black Licorice, Hot Cinnamon

The taffy is aerated on the puller, which is hooked up to a big chain drive. The old owner used to joke that if you connected the puller to the rocks at the ocean, across the street, it would pull the store into the ocean. The aerating traps oxygen molecules in the taffy, which adds volume and changes the texture. Some people add the flavors during the pulling, but we add most of our flavors during the cooking process, except the very strong flavors, like cinnamon. We tried adding that during cooking, but it created a caustic cloud of cinnamon and we had to evacuate the store for 30 minutes.

Meryl and Blagoj Vangelov

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/8d/65/8d65abc0-e6be-457b-85e4-e10e6ae654bc/julaug2017_g34_prologue-wr.jpg)

Owners

Shriver’s • Ocean City, NJ

Founded 1898

Top flavors: Vanilla, Chocolate, Strawberry

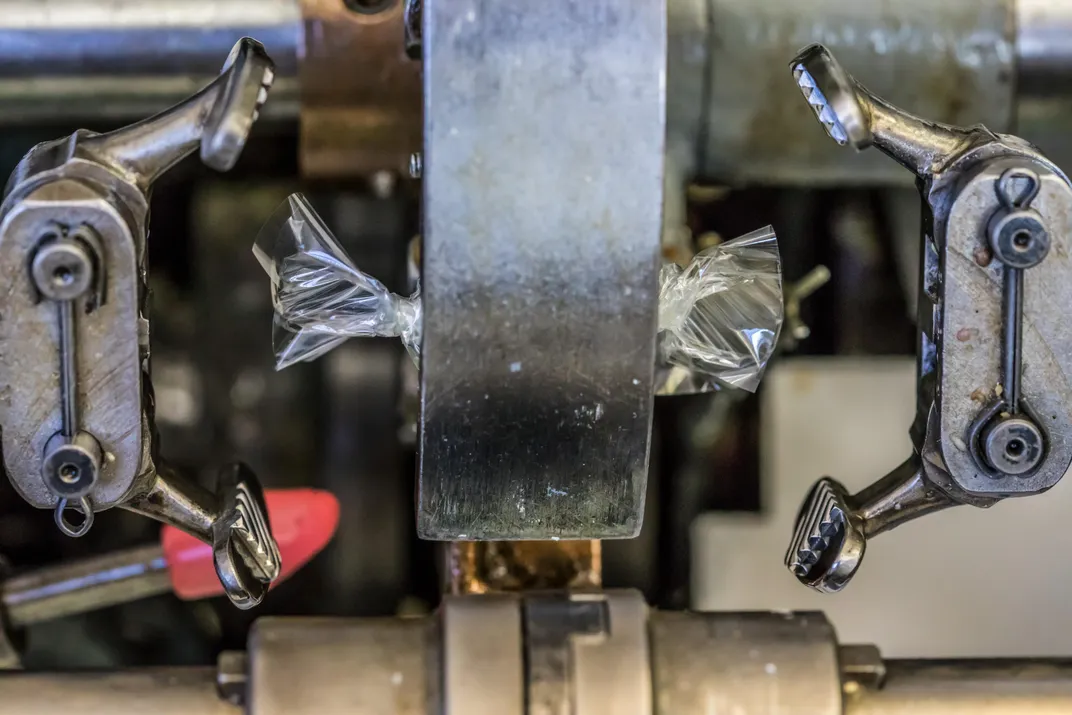

Our wrapping machines were built and shipped from Great Britain, one in the 1950s, the other in the 1960s. As the taffy travels through the machine, it gets squeezed smaller and smaller, until eventually it gets cut by a knife and then wrapped. The machine can wrap up to 500 pieces a minute, but we usually run it slower than that. Each batch of taffy is about 50 pounds. From 50 pounds, we produce about 2,000 pieces of taffy. We use white chocolate and molasses as bases to make our 70 flavors. Even with the machines, we still do a lot by hand, like packing the boxes.

Mark Igel

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer/7d/35/7d354a52-54d7-415e-8d86-823b760e5e4f/julaug2017_g21_prologue.jpg)

Co-Owner

The Taffy Shop • Estes Park, CO

Founded 1935

Top flavors: Cinnamon, Texas Pecan, Salted Caramel

Taffy in Colorado is a curious but rewarding proposition for travelers who link salt water taffy with the oceanside. It’s just a great American candy, and our shop is like a museum that still makes it. Our Model K kiss wrapping machine is in its 70th year of service. It cost about $1,900 when we bought it. They shipped it by train to Denver, and then to the mouth of a canyon at the foothills, where we are, and they had to spend another $100 to bring it up. It’s huge. It’s the gold standard. It’s built like a tank. And it’s reliable, I’ll tell you that. I think of it as a relationship, and probably one of the easier relationships I have.

Related Reads

Planning Your Next Trip?

Explore great travel deals

Smithsonian magazine participates in affiliate link advertising programs. If you purchase an item through these links, we receive a commission.